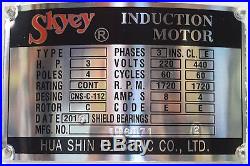

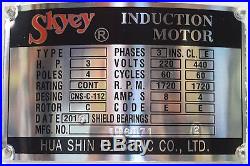

This Listing is for a. This is a very high precision milling machine. There are no shortcuts taken with these machines, they are absolutely top of the line! Here are some features of this milling machine. High Grade Meehanite Castings, High Grade of Cast Iron, Meehanite / Grade 250 (FC250/HT250). Cast Iron, ribbed for rigidity and strength. Be sure to ask if comparing with others. Entire Milling Head and Main Motor are made in Taiwan – only very high quality units used on. Hardened and Ground table and way surfaces greatly reduces wear, which maintains accuracy, and greatly extends machine life. Box Ways on Y axis means more surface area, and more rigidity. Massive 20 Wide Saddle, for extra table support. Turcite B way material on X and Y Axis for smoother table movements and longer machine life. Compare with others, you will notice the feel right away in the table handles. Head Swivels Left and Right, AND Tilts Front To Back. One Shot Lubrication system is standard equipment, which also extends machine life, and reduces. Oiling times of all way surfaces and lead screws to seconds, it is accomplished by simply pumping. High precision Inch Pitch lead screws, for ease of use and greater accuracy (5TPI Screws). High Precision Spindle with +/. 0002 or less runout for greater tool life and accuracy. Balanced pulleys in head for smooth and quiet operation. Full featured head with automatic quill feeds in 3 steps for boring operations. Precision Honed Quill Bore for tighter tolerance fit, which leads to improved accuracy when. Drilling and precision boring. Power Down Feed on quill is standard, in 3 steps. 006 Inches per revolution. Quill is Precision Ground, then Hard Chrome Plated for even longer life. Available with either step pulley speed changes, or variable speeds to suit the user’s preferences. Built in coolant sump in machine base. Tolerance Test Certificate included, each machine is checked for accuracy through a careful. Quality machine that exceeds their expectations. Normal wear items such as belts, bushings, etc. Table Size 9x 50. X Axis Travel 30 with power Feed Installed, with Full Way Support (Not over-traveled past ends of ways). Y Axis Travel 12. Z Axis Travel (Knee) 18. Distance, Spindle to Table 18. Leadscrew Type Precision Ground ACME Leadscrew W/ Double Nut Backlash. Adjustments on X and Y Axis. 200 (5 Threads Per Inch). Spindle Speed Range 70- 4200 RPM (variable). Speed Change Type Variable Speed/ Hi-Low Lever. Spindle Bearing Type High Precision Tapered Roller Bearings, Fully Adjustable. Spindle Bearing Class C7. Overall Height, Head Up 87. Height with head down For moving. Depth Front to back, rear of machine to front of knee casting 46. Rear of machine to tip of Y axis handle 51. Width X Axis Table Handles, Tip to Tip 68. Machine Weight 2550 LBS. Voltage / Phase 220 Volt 3 Phase, 20 Amp Circuit. Average time delivered is 2-10 days depending on how far from Pittsburgh you are, it could be a little longer in remote places but normally is very fast. If you would like to stop in and see one in person, we are at. Quality Machine Tools, 701 Parkway View Drive, Pittsburgh, PA 15205. We are machinists here too, so we know what we sell. This is really a top quality machine, and will last a long, long time. AND we are here for support too. We sell these machines regularly, we know them inside and out, and have been in business for many years, so if there is any question, we can help. NO extra charge for residential or anything on these, as long as a truck can get to you, its covered. THIS MACHINE IS NOT ABLE TO BE DELIVERED WITH A LIFT GATE. Check out our other auctions for more lathes and mills. The item “NEW PM-950V 9×50 VERTICAL KNEE MILL MILLING MACHINE 3 AX DRO, X PWR FD, 3PHASE” is in sale since Friday, July 15, 2016. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “qualitymachinetools” and is located in Pittsburgh, Pennsylvania. This item can be shipped to United States.

- Brand: Precision Matthews

- MPN: PM-950V

- Model: PM-950V-3PH