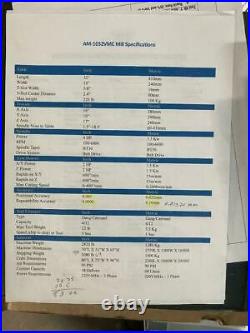

CNC Mini Machine Center VMC6030S Weiss 24″x12″ 3 SIEMENS 808D SYSTEM AND SERVO MOTORS. Standard Equipment: 3 Axis Ball Leadscrew made by TPI Robust and precise dovetail guide with adjustable V-ledges free of play Electronic controllable drive Automatic Lubricating System Front door equipped with a safety switch Base designed on two side. Front side with access to the coolant tank. Simens Control System Toolbox & Tools. Full closed loop high precision linear guide. Optional Equipment: Description Item No. CNC Benchtop Machining, it is ideal for schools and training colleges and can easily be moved between rooms. This is best hobby CNC mills, benchtop CNC mills for personal CNC machining works a Small Machining Center and Small CNC Mills Weiss Series is among the most versatile machine tools in the compact class. All models are high-performance centers, which can be set up quickly and are easy to operate, very stable, highly dynamic and low-maintenance. Thanks to the modular structure, there are numerous configuration possibilities. This allows us to customize any basic machine to your needs to achieve a perfect individual solution for you. Your benefit in a compact space: CNC cutting at low unit costs at high processing quality and unique speed. All machines are tested and certified for quality. Our machines are guaranteed for 3 years of the parts framed by us. Variety of controller options. You can use a low-cost PC controller to reduce your budget. But also through another CNC system to adapt to any application requirements. In the smallest footprint, the high quality and efficient production. At the same time, you can upgrade the two forms of external protective sheet metal. Machine bed structure can also be used high precision mineral casting parts. Through the important core components to control and upgrade quality. WEISS MODEL VMC 6030S ITEM NO 10222003 Capacity Max. Drilling capacity Ø35 mm Max. End milling capacity Ø20 mm Max. Face milling capacity Ø76 mm Milling Accuracy Positioning accuracy ±0.015mm/300mm Repositioning accuracy 0.015mm Spindle Spindle taper ISO30 Max. Spindle speed 6000 rpm/min Distance from spindle to column 200 mm Mill-Drill Head Z-axis travel 300 mm Feed speed 6000mm/min Cross Table Table 605×305 mm Longitudinal travel(X axis) 355 mm X axis feed speed 6000mm/min Cross travel(Y axis) 305 mm Y axis feed speed 6000mm/min T-slot 3 x 12 mm/63 mm Distance from spindle nose to table 380 mm Electric Supply Motor 2200W 230V/50Hz or 110V/60Hz Coolant pump 40W. Servo motor power(3 Axis). SIEMENS 1.0 KW. Servo motor torque(3 Axis). 2.2kw (AC frequency). Spindle and three-axis full servo control. Bed and milling head for the reinforcement of high-rigidity castings. Spindle synchronous pulley drive system, low power consumption, large transmission. Torque, high cutting strength. Each device is round and laser to detect the equipment to ensure high precision requirements. Spindle specifications BT30, the maximum speed of 8000rpm. Low inertia spindle design, positive and reverse speed. Spindle with domestic spindle, excellent rigidity, to meet the long time heavy load processing, running more smoothly, long life. Three-axis hard rail design, the formation of the best rigid structure, regardless of light, heavy cutting, are greatly enhance the efficiency and stability. Three-axis rapid displacement 6000mm / min, speed up, shorten the processing time. Electrical box is located on the right side of the column, shortening the depth, saving space, and the effective use of space planning. Oversized water tank capacity of 100 liters, greatly enhance the cooling effect when processing. CNC controller, using SIEMENS 808 controller, the operator panel in line with ergonomic design, with three directional positioning design, to provide convenient control features. Minimum command unit: 0.002mm. Rapid displacement speed adjustment. Automatic origin return G28. Work piece coordinate system G54-G59. Fixed cycle G73, G76, G81-G89. Rigid tapping G84, G74. The program is paused. Manual control function: manual rapid feed, jog feed, hand wheel feed. Tool length correction G43, G44 / G49. Tool radius correction G41, G42 / G40. Pitch error memory compensation. Program number serial number search. Convert to the system. Transmission interface, DNC capability. Macro programs and variables. Program graphic display function. NC control language: Chinese, English, and other languages optional. Monitoring function: full coordinate display, spindle speed display, spindle load display, PLC ladder circuit monitoring. Protection function: over-stroke protection, overload protection, interlocking function. Installation commissioning and acceptance. Installation and commissioning: the supplier sent an experienced service engineer free of charge to the customer office is responsible for the installation of the machine, debugging work. The company received the customer feedback the first 8 hours of work time to make a preliminary judgment on the customer’s questions and further guide customers to confirm and solve, if sent to the customer service maintenance, to ensure that up to 72 hours Within the customer’s location. The item “CNC Mini Machine Center VMC6030S Weiss 24×12 3 SIEMENS 808D SYSTEM AND SERVO” is in sale since Sunday, September 23, 2018. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “superdiscounttools” and is located in Nanjing. This item can be shipped worldwide.

- Model: VMC6030S

- Modified Item: No

- Country/Region of Manufacture: China

- Custom Bundle: No

- MPN: VMC6030S

- Brand: WEISS MACHINERY

- Non-Domestic Product: No