2020

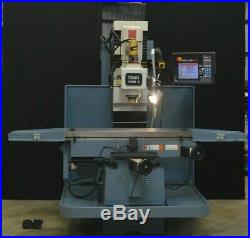

SWI TRAK DPM FHM5 Bed Milling Machine With ProtoTRAK SMX CNC Control

Welcome to Select Machine Tool. TRAK DPM FHM5 Bed Milling Machine with the ProtoTRAK SMX CNC Control. Table size 50 x 12. T-slots (number x width x pitch) 3 x 63 x 2.52. Travel (X, Y, Z axis) 40 x 20 x 24. Quill diameter – 4.13. Spindle center to column face 20.5. Spindle motor power 5 HP. Power requirement 220V, 3P, 60HZ, 17.5 FLA. Power Requirement Control 110V; 1 phase; 15A. Maximum weight of workpiece 1760 lbs. Height of table from bottom of bed 41. Maximum spindle nose to table 24. Width of machine including table 94. Length with electric box door closed 80. Overall width including full table travel 136. Overall length with electrical door open 105. Footprint 24 x 48.4. Way surface dovetail X axis; square ways Y and Z axis. Weight (approximate) net 4400 lbs. Maximum work capacities Drilling (mild steel) max. 1.00; tapping, 5/8; milling capacities, 5 inch. Way surfaces hardened and ground. Turcite coating on all slide ways. Chip pan / splash shield. ProtoTRAK SMX System Specifications. (O) indicates optional feature. Two- or three-axis CNC, 3-axis DRO. Real handwheels for manual operation. 10.4 color active-matrix screen. P/S 2 Keyboard connector. Override of program feedrate. LED status lights built into display. RJ45 Port and Ethernet card (O). Override of program spindle speed (O). 128 MB USB Thumb Drive flash memory (O). Uncluttered front panel with few hard keys. Ballscrew and motor assembly installed on quill. Software Features general operation. Clear, uncluttered screen display. English language no codes. Soft keys – change within context. Selectable two or three-axis CNC. Color graphics with adjustable views. Convenient modes of operation. Incremental and absolute dimensions. Jog at rapid with override. Powerfeed X, Y or Z. Do One CNC canned cycle. Teach-in of manual moves. Servo return to 0 absolute. Tool offsets from library. Go To Dimensions (O). Spindle speed setting with manual override (O). Auto Geometry Engine (O). 3-axis geometry programming (O). Tool Path programming (O). Scaling of print data (O). Multiple fixture offsets (O). Programming of Auxiliary Functions. Three-axis Geometry conversational programming (O). Automatic diameter cutter comp. Look graphics with a single button push. List step graphics with programmed events displayed. Conrad automatic corner radius. Math helps with graphical interface. Auto load of math solutions. Tool step over adjustable for pocket routines. Pocket bottom finish pass. Selectable ramp or plunge cutter entry. Subroutine repeat of programmed events. Rotate about Z axis for skewing data. Mirror of programmed events (O). Global data change (O). Clipboard to copy events between programs (O). Set Up Mode Features. Tool length offset with modifiers. Tool path graphics with adjustable views. Program run time estimation clock (O). Trial run at rapid. 3D CAM file program run. 3D G code file run with tool comp. Real time run graphics with tool icon. Countdown clock to next pause or tool change (O). Program In/Out Mode Features. Simple program storage to floppy. Converter for prior-generation ProtoTRAK programs. DXF/DWG file converter (O). Selection of file storage locations (O). Automatic file back-up routine (O). Preview graphics for unopened files (O). Countdown clock to next pause or tool change. Total program time estimator. Scaling of print data. Tool path conversational programming. Mirror of programmed events. Copy with or without offsets. Clipboard to copy events between programs. Automatic file back up routine. Preview Graphics for unopened files. USB Thumb Drive flash memory, 128 MB or more. Networking via RJ 45 port. The DXF File Converter Option. Import and convert CAD data into ProtoTRAK programs. DXF or DWG files. Easy, prompted process you can do right at the machine. CAM Out Converter Option. Save ProtoTRAK files as CAM files for running on different controls. Electronic Handwheels on X and Y (replaces the mechanical handwheels). TRAKing of programs during program run. Selectable Fine/Coarse handwheel resolution. We want you to be happy and we also want to help you in any way possible. So that we may earn your business. We want to build relationships with our customers and the best way to do that is by providing quality products, honest representations, value, and service. Again, we want to thank you for your time and interest and we look forward to earning your business in the near future. In order for this to be an enjoyable experience, please ask all questions before purchasing. And we will try to reply within 24 hours. Thank You for stopping by and please view our other items. The item “SWI TRAK DPM FHM5 Bed Milling Machine With ProtoTRAK SMX CNC Control” is in sale since Monday, February 3, 2020. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “selectmachine” and is located in Roanoke, Virginia. This item can be shipped to United States.

- Machine Type: Milling Machine

- Power Source: Electric

- MPN: Does Not Apply

- Brand: Southwestern Industries

- Control: CNC

Comments Off