2021

Sixis 101 Milling Machine With Accessories

Comments Off

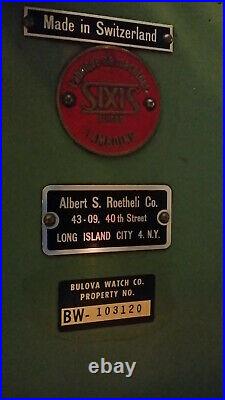

A year or so ago I listed my Sixis 101 Mill complete with collets and inclinable indexer. I’ve owned this machine over 20 years and used it once. It was originally made for Bulova in Woodside, Queens, NYC, When they closed the factory it was transferred to Hamilton in Lancaster, PA. He was a mechanical engineer who made up the phase converter you see in the pictures. The motor started out as 440V and rewired to 220V 3-phase. The mill works very well, I do not recall any play in the bed, it comes with a vise, a right square and a milling quill that was intended for cutting watch or clock gears. NO collets – they were 12mm. The machine is currently in a climate controlled storage unit. PLEASE, if you have any questions, JUST ASK! The item “Sixis 101 milling machine ex Bulova and Hamilton watch factories” is in sale since Monday, September 28, 2020. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “neilywatch” and is located in Red Bank, New Jersey. This item can’t be shipped, the buyer must pick up the item.

Comments Off

Offered here today is a Sixis 101 milling machine. I believe it to be about 70 years old. It is complete and running. This was the smallest mill Sixis made, designed based the Deckel setup and made to compete with the Aciera F1. It first saw service with the Bulova Factory in NYC, then was transferred to Hamilton, in Lancaster, PA, in the early 1960′s. It originally was made by Perrenoud in Switzerland. Sixis has a great reputation for Quality. As I said, it works. Will need to be greased and adjusted. It comes with a mechanical phase converter. The guy who I bought it from was a mechanical engineer and made this setup. He also stated he had the motor rewound from 440v to 220v. He recommended that for best results, to use the mechanical converter instead of a VFD. There is a milling quill that was made from a watchmakers lathe, and indexing attachment, and a tray of 12mm Schaublin collets. It is all metric except for one fractional chuck. Collet numbers are 4,5,6,7,8,1/32,9,10,11,12,13,14,15,16,17,18,19,20,22,24,25,26,28,30,32,34,35,36,38,40,42,44,45,46,48,50,52,54,55,56,58,60, and 65. I will leave it set up for 2 more weeks if you want to see it running. After that I will dismantle it and put it in storage. The item “Sixis 101 Mill ex Bulova and Hamilton Factories running plus accessories” is in sale since Sunday, October 13, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “neilywatch” and is located in Red Bank, New Jersey. This item can’t be shipped, the buyer must pick up the item.

Comments Off

SIXIS S102 ISO 30 SPINDLE ASSEMBLY FROM A WORKING S102 MILL. COMPLETE ASSEMBLY TO DRIVE ISO SPINDLE AND ALSO CAN BE USED AS A VERTICAL HEAD WITH PROPER BRACKET. ISO 30 SPINDLE WITH 0.5 HP MOTOR. SPINDLE PROX 70MM DIAMETER. MOTOR 220/440 3 PHASE 60 CYCLES, SET FOR 220. INCLUDES PULLEY GUARD, NO CENTER MOUNTING BOLT, EASY TO REPLACE AND ISO 30 DRAWBAR. HAS PLUG AS PICTURED. THE COVER FOR THE GEAR HOUSING IS DIFFERENT THAN ANOTHER UNIT HERE. THIS ONE IS PLASTIC WITH CENTER HOLE, OTHER IS SOLID (PIC FOR COMPARISON) NOT SURE WHY THE DIFFERENCE, HAS NO AFFECT ON USE. EVERYTHING LOOKS FINE INSIDE. PLEASE MESSAGE ME IF INTERESTED, CAN TRY TO HELP. The item “SIXIS S102 MILLING MACHINE COMPLETE ISO 30 SPINDLE & MOTOR DRIVE VERTICAL HEAD” is in sale since Friday, October 6, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “earlypearl” and is located in Tunkhannock, Pennsylvania. This item can be shipped to United States.

Comments Off

This machine would be great for someone who is in the jewelry or horology field or even someone making high precision small instruments. Here is a description of the machine on Lathe Archives: Sixis 101 Designed for the precision machining of small components used in the instrument, watch, jewellery and similar industries, the Sixis 101 was a superbly made miniature universal miller capable, in the right hands, of the finest quality work. Like the better known and very similar (but rather lighter and smaller) Aciera F1 it is not as big as photograph might suggest and, even allowing for the full extent of the table’s travel and the length of the operating handles, it is possible to mount and work one within a space equal to a square with a side length of little more than 24 inches (580 mm). With its cast-iron base plate the (58 kg/127 lbs) machine could be either bench mounted or fitted to the maker’s heavy 60 kg (130 lbs) cabinet stand that was neatly arranged inside to hold a range of accessories. Consisting of a motor, a smooth-running 3-step flat pulley and a 2-speed gearbox, the drive system was arranged as a neat, integral unit and able to power the spindle in either a horizontally or vertical position (although in the latter case a support casting part number 211 was necessary) with a total of six speeds that spanned 125 to 4000 rpm. However, these speeds were not fixed, the factory being able to vary the speed range according to a customer’s requirements by fitting different pulleys – although the gearbox speed range always remained unchanged. The options available were: Geared speeds: 125, 250, 500, 1000, 2000 and 4000 rpm Direct (belt) drive: 1000, 2000 and 4000 rpm 2000, 4000 and 6000 rpm 6000, 8000 and 10000 rpm 9000, 12000 and 15000 rpm Two T-slotted tables were offered: a plain right-angle type and a useful swivelling, tilting and inclinable version both of identical size at 200 mm x 600 mm. The table feed screws were hardened and ground and (on the example used by the writer) ran through backlash-adjustable bronze nuts; each axis was also fitted with a lever feed, the very sensitive feel obtained through the long (adjustable) activating arms being considered an advantage when machining delicate jobs. The length of both the longitudinal and vertical feeds was just under 6 inches (150 mm) and the traverse a little less than 4 inches (100 mm). Large and clearly engraved micrometer dials were fitted, graduated in intervals of 0.001″ on the longitudinal and traverse feeds and at intervals of 0.0005″ on the vertical. All feeds were by hand, there being no provision for a power fitting, though rumors persist of one offered by a third-part supplier and not included in the main catalogue. Unfortunately, and a surprising omission on a machine developed for ultra fine work of a complex nature, the vertical head had no quill movement, either fine or quick-feed. Consequently, all vertical travel had to originate from the knee – a serious inconvenience when the need arose to drill or machine downwards along an inclined axis. The direct competitor to the Sixis 101, the Aciera F1 did offer such a fitting (part 01-87-1504-01) and it is just possible that Sixis did too, but no details have come to light. The collet fitting was the popular and easily-obtained Schaublin type W12.. It runs on a VFD using 110V and is in good working condition. After refurbishing the machine I have never used it so after moving it twice I have decided to sell it (the cosmetic scratches came from moving). The machine will be ready to be picked up on a pallet and all accessories packed in boxes. The item “Swiss Sixis 101 Universal Milling Machine” is in sale since Friday, November 17, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “allennvalerie” and is located in New Braunfels, Texas. This item can’t be shipped, the buyer must pick up the item.

Comments Off