2024

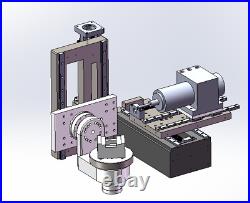

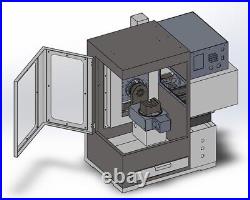

5 Axis CNC Milling Machine V4 Desktop with Horizontal Spindle with Metal Enclosu

Overall size L700W400H510mm Workbench size 140130mm Total machine weight 60Kgs Workbench maximum load 10Kgs X, Y, Z three-axis effective stroke X160Y200Z125 A, C rotary axis are both Harmonic Drive effective stroke A-20–+110 degrees, a total of 130 degrees, C-axis 360 degrees unlimited. 5-axis effective processing range X150Y150Z125 A-axis rotary axis parameter 1:50 grinding worm reducer, cross roller rotary bearing C axis rotary axis parameter 1:50 grinding worm reducer, cross roller rotary bearing Three-axis ball screw X, Z-axis 1204 C7 Y-axis 1605 C7 Linear guide X-axis adopts silver MGN12 linear guide, Y-axis adopts silver MGN15 linear guide Z-axis adopts HGH20 Rack 6061T6 aviation aluminum + force parts 45 steel quenching and tempering, the whole machining center drilling, fine milling, tapping. Processing materials Plastic, wood, aluminum. Copper, gold, silver, wax, etc. Processing speed 2500mm / min (mm / min) (depending on the material, processing speed is different) Spindle model 65mm diameter 800W electric spindle 24000 rpm Dustproof organ dustproof + oil seal dustproof (rotary table waterproof treatment) Tool diameter ER11 0-7mm Fixture Steel fixture, reserved for er50 collet holder, 63 80 chuck. Standard offer of Desket-V4. One complete horizontal 5-axis CNC milling machine, BLDC Servo Motor, C5 Ground ball screw 1204 and 1604, HIWIN dual linear rails, Harmonic Reducer the 5-axis Control box/Power supply Power cord USB cable 1 set of hexagon wrench Self centering vise 8-55mm A set of ER11 wrench Two ER11 collets 4 test tools 8 pieces (2, 4mm end mill, R1 ball cutter, 0.2 point cutter) Gauge block Electronic handwheel 4 pieces of test substitute wood Spindle motor cooling system (pump). Are servo motors standard, or is that an option? Servo motors of the V4 are standard offer and ground ball screw, harmonic drive r5-axis. Does only the “C” rotary axis use a harmonic drive, does the “A” axis also use a harmonic drive? A and C rotary axis are both harmonic drives. Does the “Y” axis require a counter-weight? (I noticed a cable in one of the photos on the webpage). No need for a counterweight. Are all the motors and electronics well sealed against cutting/cooling fluid (water-soluble)? With enclosure, yes it’s well sealed. Is the enclosure sealed against cutting/cooling fluid and is there a reservoir (sump) at the bottom of the enclosure that is suitable for coolant recirculation? Yes, there is a reservoir at the bottom for the coolant recirculation. Is the spindle water cooled? If so, is the pump and cooling system reliable? Yes, the spindle is water-cooled with cold exhaust and cooling fan, pump and cooling system provided is reliable. Is there any disadvantage (other than the additional cost) to get the high-speed spindle? Speed mainly depends on the needs of processing materials. With high speed, the finish and cutting load of each edge will be smaller, but the tool will wear out faster. Is there any kind of semi-automated tool setting mechanism? Is there a touch-off sensor? There is an automatic electronic tool setting. Do you provide a post-processor for Fusion 360 that works well? Yes, Fusion 360 post-processor is provided. Do you provide any post-sales support for setup, configuration, trouble-shooting? If you have WeChat, we have a group of more than 10 already from worldwide and our engineer in to take your questions.

Comments Off