2024

VEVOR X-Axis/Z-Axis Power Feed Table Mill for Milling Machine 450/150 in-lb

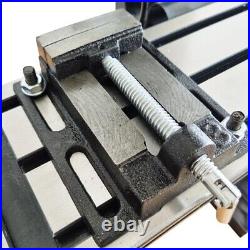

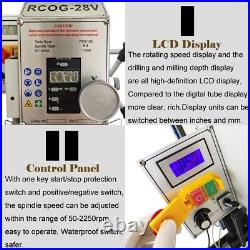

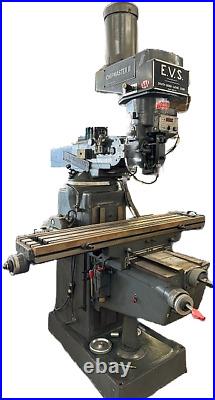

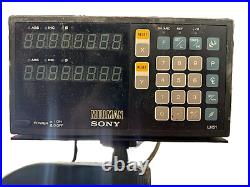

VEVOR Milling Machine Power Feed. Our power table feed brings a stable transmission ratio and high load-bearing capabilities. Take control of speed with ease using the manual lever and automatic knob. Ideal for 5/8” end shaft diameter machines and X-axis/Z-axis milling machines. Equipped with Gleason spiral bevel gears, our milling machine power feed ensures a stable transmission ratio, low noise output, high transmission efficiency, and excellent load-bearing capacity. With noise levels? 85dB, providing a conducive environment for your work or study without disruptions. Our power feed table mill is equipped with overload protection. In instances of rapid transmission, if there is a collision or instantaneous reversal between the tool and the workpiece, a special security mechanism safeguards the gearbox’s plastic gears and electronic components from damage. Our compact and lightweight power table feed is easy to install and operate. The control panel features clear functions, making the operation straightforward. Additionally, we provide a detailed installation and user manual, ensuring you have all the information you need to operate effectively. Our power feed milling machine comes with a set of sturdy metal parts that are built to last, including 1 x copper gear, 1 x install the retainer plate, 3 x fixing screws, 2 x limit switch springs, 15 x adjusting shims, 1 x bearing inner ring, and 1 x copper gear gasket. Here we will provide you with 3 types of Power Feed for your option: X-Axis 450 in-lb, X-Axis 150 in-lb, Z-Axis 450 in-lb. Ultimate High-Compatibility Solution: Our power feed table mill Includes everything needed to mount on most knee-type mills with a 5/8” end shaft diameter that shares the same installation pattern, such as Bridgeport, Precision Matthews, Enco, Jet, Sharp, Acer, Webb, and others. Infinitely Variable Speed Control: With the continuously variable speed knob, you can adjust the speed according to your needs. Our milling machine power feed offers a rated torque of 450 in-lb(50.7 NM)/150 in-lb(16.9 NM), a maximum speed of 200 RPM, a maximum feed rate of 965 mm/min, and a maximum return speed of 1385 mm/min. Highly Stable and Efficient: Featuring Gleason spiral bevel gears, our power table feed boasts stable transmission ratios, low noise, high transmission efficiency, and high load-bearing capacity. Plus, it comes with a special security device that protects the gearbox plastic gears, and electronic components from damage in the event of tool collision or sudden reversal during rapid transmission. Easy to Use, Manual or Automatic: Our power feed milling machine offers two different speed adjustment modes: manual and automatic. With manual control buttons, you can adjust the speed as needed. Alternatively, set the device to automatic constant speed mode for hands-free operation, making your milling tasks a breeze. Designed for X-axis Direction: This power feed woodworking enables smooth movement in the X-axis/Z-axis direction. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. Please be aware that. Please DO NOT fill in the PO Box address. California Warehouse: City of Industry, CA. New York State Warehouse: Perth Amboy, NJ. Georgia Warehouse: Austell, GA. North Carolina Warehouse: Grove NC. Oregon Warehouse: AIRPORT WAY Portland, OR. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices.

Comments Off