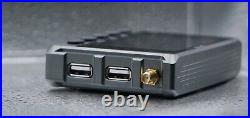

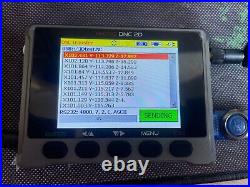

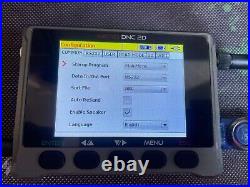

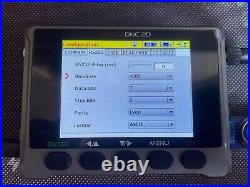

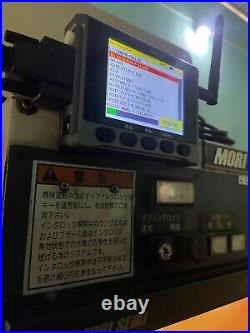

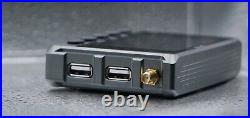

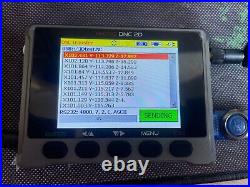

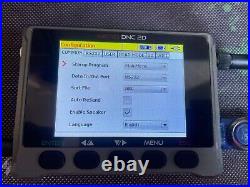

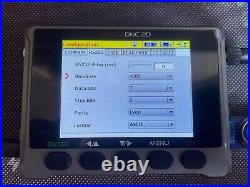

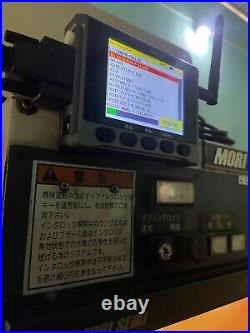

MICRO DNC 2C/MICRO DNC 2D (called DNC 2) is a device used to transmit or receive G-code programs with CNC machines – that is the basic function of the DNC 2 device. The MICRO DNC 2D is a prototype of the MICRO DNC 2C with a redesigned aluminum case and flexible plastic keyboard. The software inside still uses the firmware of MICRO DNC 2C. So basically MICRO DNC 2D and MICRO DNC 2C are the same. DNC 2 is designed to optimize and simplify program transmission to CNC machines (compact, does not take up working space, very high stability, good anti-interference), replacing computers or some other devices. Complex old equipment to transmit G-code program to cnc machine. You can transfer programs from the DNC 2 memory (4GB memory) or transfer programs from a USB stick (up to 64GB memory). Can transfer the program into the CNC machine memory, or drip large programs to the CNC machine through the CNC machine’s DNC function. You can receive data from the CNC machine to the DNC 2 device program storage, tool offset parameters, CNC machine parameters… DNC 2 can connect to a computer via wireless LAN (wifi network). There will be software installed on the computer. From the software on your computer, you can copy the program from your computer to DNC 2 or vice versa from DNC 2 to your computer. Notification can be sent to the machine operator (notification on the DNC 2 screen). Execute the program transmission command for DNC 2 from the software on the computer, you can monitor the status of the DNC 2 device transmitting or stopping, displaying % of the program being transmitted… Computers and DNC 2 connected to the same WIFI network can connect to each other. If connecting to different wifi networks, it will not work. A very special function on DNC 2 is the ability to simulate toolpaths, you can simulate programs in memory or USB cards. DNC 2 device has 4 selected languages for display (English, Japanese, Italian, Vietnamese). DNC 2 has data formats (ASCII, EIA, ISO). There are instructions for using the basic functions on the DNC 2 screen (HELP/INFOR page). In addition, you can create or edit programs on the DNC device screen. You can use the virtual keys on the DNC 2 or you can use an external USB keyboard. (the device will recognize the keyboard and you will compose or edit the program very simply). DNC 2 device has two USB ports (you can only use 1 USB port at a time). The device has 1 RS232 port to connect to CNC machines. There is 1 power port to supply 12V DC power from outside. Parity setting – (even-odd-none). There is an automatic transmission mode when the program ends (used for processing parts with many repetitions). Package includes DNC 2, 2 meter long RS232 DP9-DP25 cable, 12V AC-DC power adapter. Customer service throughout the process of customer use. We can assist in setting up DNCdevice and CNC working together. Products are warranted for 1 year. Link to download the user manual of the MICRO DNC 2 device. Link 1-ONEdriver : MANUAL DNCdevice. Link 2- Mediafire: MANUAL DNCdevice.