2025

Bridgeport X Axis Power Feed 6F-A

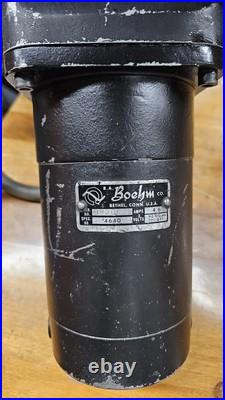

Up for sale is a complete Bridgeport 6F-A version power feed for the table x axis. It is the first version having a seperate box that mounts to the column and houses the pc board. It is the upgraded newer style Seco electronics pc board. This unit was completely taken apart, cleaned and inspected for wear. All the major components were found to be in excellent condition and just a few minor parts were replaced to bring it back to like new condition. Cleaned armature, field windings, and motor end bells of carbon dust and oil residue. Installed new motor bearings, brushes, brush caps and brush seals. Replaced motor wire harness. Tested armature on a growler and verified no shorts, opens and ground faults. Checked commutator for wear and concentricity with dial gauge and trued up the commutator on a lathe with a Jacobs armature chuck. Cutting a commutator on centers will make it true to the center, but I have found that most centers are not true to the bearing and can be off as much as a thou. Cutting with a Jacobs Armature truck ensures the bearing surface is true with the commutator surface. Replaced clutch arm bushing. Install new directional microswitches. Install new oil seal. Inspected main spiroid drive gear for wear and found none. Install new cover gasket, switch boots, and potentiometer knob. Replace safety handle spring, drive pin, washers, bushing & locknut. They are usually dirty on the outside and almost always have sludge in the gear train with unreadable oil sight gauges. How soon before it needs service or repair? Theyr’e between 40 to 60 years old. Full disclosure, no hidden defects, no disappointments.

Comments Off