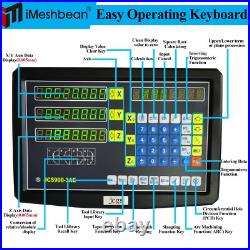

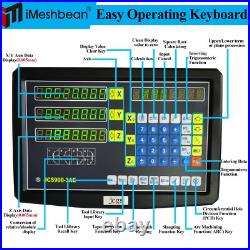

2 Axis Digital Readout Display/ DRO/Encoder with 12″ (300mm) & 36″ (900mm) High Precision Linear Optical Scales/ Grating rulers/ Linear Glass Scales Set, Multi-Function for series I Bridgeport with 9×42 table, TTL Industrial Measuring Tools, ± 0.5/1/2/5/10? M Resolution, 1m/s, 110-240V Wide Voltage. 12″ (300mm) & 36″ (900mm) Travel Length? 2 Axis DRO & 12″ (300mm) & 36″ (900mm) Scales Kit. Targets for series I Bridgeport with 9×42 table. This DRO kit is commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy. Use of DROs is not limited to manually operated machines. CNC machines can usually be switched to manual operation, and in this case a form of DRO is simulated on its control panel. Scales include? 140mm extra length for secure mounting (total length = travel + 140mm). High Precision & Resolution? ±1/ 2/ 5/ 6/ 10? M resolution (adjustable). 5? M grating pitch with TTL signal output for unmatched accuracy. Works with? 5V TTL signals (NPN output) for seamless integration with encoders or scales. 9-pin connector supports TTL square-wave input (pins 1-4: +5V, GND, A, B). 60m/min scanning speed (40ips) for high-speed machining. 2 Axis Display??? 10 Wide LED Display shows real-time X/Y coordinates with? 1m/s tracking speed. A multifunctional 2-axis digital viewing instrument/digital reading gauge is specially designed for numerical control machines, providing high-precision measurements with a resolution of 0.1? M for efficient and accurate machining. Characterized with high scanning frequency, quick graphic machining, low measuring error and powerful functions, It has a good capacity of resisting disturbance. Multi-Functionality? SDM 200+ memory sets, power-off retention, bevel processing, and calculator. Advanced functions–1/2 centering, error compensation, arc/circle drilling, zero setting, tool compensation etc. Industrial-Grade Durability?? IP53/IP64-rated casing with ABS Shell(DRO), or aluminum alloy housing with anti-corrosion chrome plating (TTL glass scales), is dustproof&scratch-resistant. Withstands -10°C to 70°C(14? To 158?), 90% humidity, andand 600m/s² impact resistance for harsh workshop environments. Easy Installation? Includes? 3m shielded signal cable with metal shell for noise immunity. Pre-calibrated scales; zeroing and offset adjustments via intuitive interface. Wide Voltage Compatibility:? 100-265V AC input for global use (built-in voltage regulator). Includes L-shaped dust bar, brackets, screws, and manual. Application? The Multiple function digital readout kit is specially designed for mechanical process. It is suitable for lathe, milling machine, grinder, boring machine, spark tester and more. Milling Machines: Track X/Y/Z coordinates for complex part machining. Lathes: Monitor spindle position and cutting depth (lathe-specific functions included). Grinders/EDM: Measure material removal rates and electrode alignment. Drilling/Cutting: Ensure precise hole positioning and linear cuts. CNC Systems: Simulate manual mode with DRO interface. 2 Axis LED Digital Readout. Radius/Diameter function (lathe machine); 21. Z+Y sum (lathe machine). ± 1µm;± 2µm;± 5µm;± 6µm;± 10µm / 0.0002 (at 20 deg C). Transmission infrared optical measurement system, infrared wavelength 940nm. 5V ± 5% DC. 50 Hz-2 KHz, ? 180m / s. 1m / S (1? M). 16ms, ? 600m / S². 60 m /. IP53 (dust-resistant) / IP64 (splash-proof). 12″ and 36″ High Precision TTL Linear Scale. 5? M (0.005mm) 0.0002. ±0.005 mm or 0.0002 (at 20 deg C). Reference marks at interval of 50mm. Why Choose This DRO? Cost-Effective Precision: Combines industrial-grade accuracy with TTL compatibility. Versatile Compatibility: Fits manual machines, CNC systems (manual mode), and DIY projects. Future-Proof Design: Expandable to 3-axis with add-ons; supports custom scales. User-Friendly: Intuitive menu, calculator, and memory functions reduce setup time. The DRO only allows TTL square wave signal input through 9 pins connector, designed to match multi kinds of linear scale with resolution 1µm, 2µm, 5µm, 10µm. Note: the DRO resolution must be set to completely match the linear scale precision. Pin 1 to 4 connects +5V, 0V, A, B, and the pin 5-9 are blank. 10,000+ switch cycles. Spare Fuse on display unit for reliability. Robust ABS casing, full-closed design ensures its clean and IP54 dust resistance, safety increased. Having a good capacity of resisting disturbance. Durable keyboard is easy to modify its parameter to make it applicable for various machine tools. Custimized Travel length TTL Scale. The fully sealed readhead of high accuracy glass linear scale adopts 5 bearing system design, which ensures repeatable positioning, and is with perfect structure of the profile takes it match IP67 protection class. 3m metal shielded signal cable with multilayer for noise immunity. 9-pin interface supports TTL square-wave signals (NPN output). High speed, can reach 60 Meter/minute for the resolution of 5 micron. Mount scales perpendicular to the machine axis to avoid cosine errors. Use shielded cables and avoid running parallel to power lines. “L” Bar for protection against debris and coolant. Multiple installation holes for your convenient installation. Ideal choice for limited installation space. Scale Width & Height = 28 x 30 mm (L0 = travel length, Total length = travel length + 140mm). Widely used for manual machine, such as milling machine (for Bridgeport Mill, Knee Mill, Rong Fu 31 mill / drill, Grizzly Mill, etc), drilling machine, grinding machine, lathe, EDM, linear cutting machines, boring machines etc. You can use it to achieve the functions of movement controlling, position monitoring, and coordinate measurement, etc. Bridgeport-Type Mills: Track knee mill table movements. EDM Machines: Align electrodes with micron precision. Surface Grinders: Monitor workpiece thickness during grinding. Drilling Jigs: Ensure repeatable hole patterns. Brand: iMeshbean 100% High Quality. We have proudly designed our own products and successfully created our own brands in the industries. In order to provide the peaceful shopping experience, our dedicated customer service teams can response to all the requests within 24 hours. We honor 30 days’ return on any products customers are not satisfied. Being our customer is a wise choice! (No service on Weekend and public holidays). All return products should be in brand new state with all accessories included.