2025

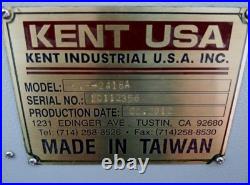

KENT USA KVR-2418A Vertical Machining Center 24 ATC X 24 Y 18 CHILLER LOW HRS

Fanuc 0iM-D axis cnc control. Large working capacity with 24″ x 18″ x 19″ travels, and 30″ x 18 table. Powerful 15HP high torque spindle motor – 10,000 RPM with spindle chiller system. Heavy duty “Roller” type Linear guide ways outperform ball-type linear ways. Roller Guide Ways – 44% More Rigid Than Ball Guide Ways!! 4th Axis Ready pre-wired with cables and connectors for servo and air. Coolant wash-down and Air hose connections up front for operator convenience. High flow high capacity coolant system with built-in chip flush and chip auger conveyor. Automatic coolant tank oil skimmer with adjustable timer. Swing-out operator panel for easy and convenient machine operations. Certified Meehanite® FC-25 grade machine casting for superior dampening and stability. 610 mm (24.0 in). 460 mm (18.1 in). 480 mm (18.9 in). 760 x 460 mm (29.9 x 18.1 in). 600 kg (1320 lb). T-slots: 4 slots (width x pitch)……………… 14H8 x 100 mm (0.55 x 3.94 in). Table height from floor approx. 930 mm (36 in). Spindle nose to table top……………………… 100580 mm (3.922.8 in). Spindle center to column……………………… 500 mm (19.7 in). 11 kW (15 hp). 70 Nm (52 ft-lb). 76 mm (3.0 in). 150 mm (5.9 in). 250 mm (9.8). 5.5 kg 12.1 lbs. Tool change time (TTT)……………………….. 36/36/32 m/min (1417/1417/1260 in/min). 15 m/min (590 in/min). 1.8/1.8/3.0 kW (2.4/2.4/4.0 hp). Linear “Roller” type, 30 mm (1.2 in). 32 mm (1.26 in). ±0.005 mm (±0.0002 in). ±0.002 mm (±0.0001 in). 20KVA / 3PH / 220V. 5.5 bar (80 psi). 240 L (63 gal). 2 L (0.5 gal). 271 cm (8.9 ft). Machine width x depth………………………… 235 x 291 cm 7.7 x 9.5 ft. 3650 kg 8030 lbs. 245 x 227 x 252 cm 8.1 x 7.5 x 8.3 ft. 4100 kg 9000 lbs. (PLEASE CHECKOUT THE OTHER ITEMS FORSALE). PLEASE CHECK OUT MY OTHER AUCTIONS.

Comments Off