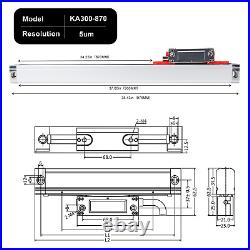

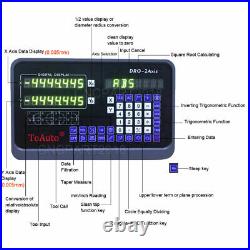

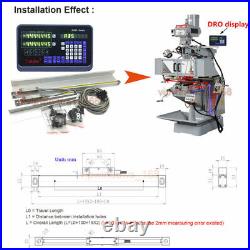

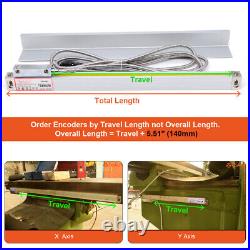

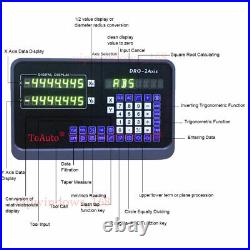

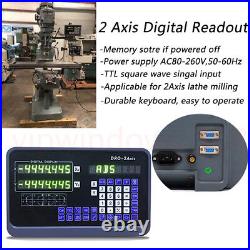

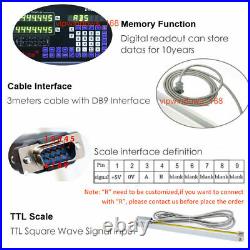

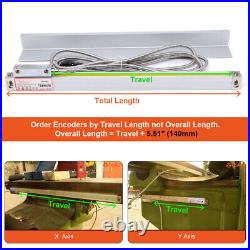

Applications This DRO kit is commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy. Use of DROs is not limited to manually operated machines. CNC machines can usually be switched to manual operation, and in this case a form of DRO is simulated on its control panel. Jewelry Design & Repair. Digital Readout& Linear Scale. Welding & Soldering Tools. Rosin Heat Press Machine. 3001000mm Linear Scale 2 Axis DRO Digital Readout for Bridgeport Mill Lathe, US. 3001000mm Linear Scale w/ 2 Axis DRO Digital Readout for Bridgeport Milling Lathe, US. This DRO kit is. Commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy. Linear scale 300mm+1000mm (12″ & 40″). 2Axis digital read out with holder and mount bracket. Mounting base for scales. Protective cover for scals some screws for scales. So to accomplish a perfect project. To offer excellent long-distance viewing. DRO providing a two axis display with pitch circle calculator, diameter/radius conversion, absolute and incremental toggle, and inch metric toggle. Digital readout kit can avoid wasting weeks to check machine precision. Lifetime free technical supp. Readout allowable input signal. Allowable input signal frequency. Less than 5M Hz. Max resolution of digital display length. 5µm(0.005mm/0.0002). Min resolution of digital display angle. (11.2″7″2.8). Backup data for power fail. Power off Memory by E2PROM for ten years. Q1 : are the length 300MM, 900MM travel length or total? Answer : all are travel length. Q2 : what does the dro measure to? Answer : measure to 0.005mm, 0.0002inch (1inch=25.4mm). Q3 : Can i cut the scales by myself? Answer : Technically NO, it maybe unavailable after cutting. Q4: Do you have English user manual? Answer : yes, it comes with the dro box. Q5: Do you have other cheaper types, such as measure to 0.001mm? Q6: Is it easy to mount these scales and dro? Answer : Please must check the scale pin definition (1,2,3,4,5,6,7,8,9), which is very important!! Q8: How to switch between milling machine lathe grinding machines. How to switch Mill type to Lathe type? Answer : Please see the following video. (press 6 times after DRO powers on). Q11 : How to set. Radius to Diameter Mode? Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Like LCD screen, industrial burner accessories, printer accessories, instrument accessories, and other fields solutions, we supply Sumsung, LG, AUO, Xinje, Riello, Honeywell, Dungs, Mitsubishi, Siemens, Heidelberg machine parts and The international famous brand accessories etc. Due to time zones, our reply to your questions may not be immediately. But within above working time, we w. If it’s non-workdays, please kindly be patient and wait till Monday.