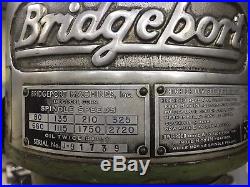

General Info: Stock #: SB-181040 Location: Stone Mountain, GA Brand: Millport Model: 3VH Serial #: 84995 Year: 1984 Approx. Check out the video on the listing to see it in operation. We are glad to show under power. Video will open in a new window. If you have any specific questions or would like to set up a time to view this piece of machinery feel free to contact the contact person for this listing 7 days a week. Purchaser shall pay The Equipment Hub a late penalty on all amounts over 30 days past due computed on an interest rate equal to 18% per annum. The Equipment Hub SHALL NOT BE RESPONSIBLE FOR THE CONSEQUENCES OF PURCHASER’S FAILURE TO INSPECT THE EQUIPMENT OR MERCHANDISE OR FOR ANY INACCURACIES, INSUFFICIENCIES, OR OMISSIONS IN SUCH DESCRIPTIONS, SAMPLES, TOLERANCES AND/OR SPECIFICATIONS. The employees or representatives of The Equipment Hub are not authorized to make any statement or representation as to the quality, character, size, condition, quantity, etc. Of the equipment and merchandise offered for sale inconsistent with these Terms and Conditions. Any such statements made will not be binding on The Equipment Hub or be grounds for any subsequent claim. All implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed and excluded from this agreement. Care is taken to give reliable descriptions but these are not guaranteed and prospective purchasers are advised to check vital details. We also reserve the right to correct any stenographic errors. All specifications and descriptions of said goods are approximate only. THE WARRANTIES DISCLAIMED HEREUNDER INCLUDE, BUT ARE NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No salesman or other representative of The Equipment Hub has authority to make any warranties. It is Purchaser’s responsibility to inspect the goods and to ascertain if the specifications, tolerances, descriptions and condition of the goods conform to the Purchaser’s requirements. Purchaser does hereby discharge The Equipment Hub from any and all liability directly or indirectly resulting from the presence of the aforesaid chemicals or materials, including and not limited to any and all liability directly or indirectly resulting from the failure of The Equipment Hub to give more specific warning with respect to individual articles or substances or from the inadequacy of any warning. Suggestions by The Equipment Hub regarding the design, specification, tolerances, use or suitability of the Products are made in good faith but are not binding upon any party and do not give rise to any liability by The Equipment Hub. MODIFICATIONS/ SEVERABILITY: Purchaser acknowledges that these are the only Terms and Conditions of sale, and is intended by the parties as a complete and exclusive statement of the terms of their agreement. This supersedes all prior agreements, written or oral. Any variation from the terms hereof contained in the Purchaser’s acceptance is hereby rejected. The agreement of which these terms are a part can be modified or rescinded only in writing signed by The Equipment Hub. If any provision of the invoice or these Terms and Conditions is determined illegal or unenforceable, it shall not affect the enforceability of any other provision or paragraph of the invoice or these Terms and Conditions. The remedy hereby provided shall be the exclusive and sole remedy of Purchaser and any right to consequential and incidental damages is excluded. The item “Millport 3VH 2HP Variable Speed Milling Machine with Servo 140 Power Feed” is in sale since Sunday, August 5, 2018. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “equipmenthub” and is located in Stone Mountain, Georgia. This item can be shipped to United States.

- Modified Item: No

- Custom Bundle: No

- Non-Domestic Product: No