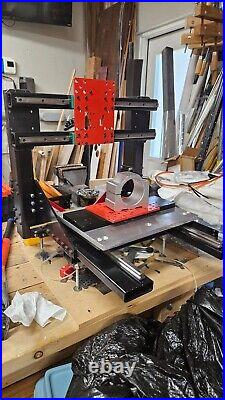

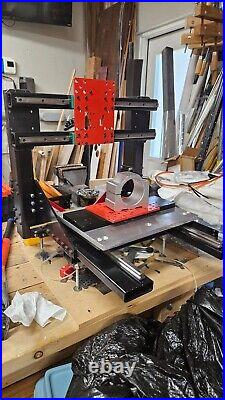

This is a partially assembled DMC2 CNC 3-axis mill KIT, 220V. 3 of 4 pictures have come from the DMC website as reference of what it should look like and machine once assembled. Most relevant surfaces have been ground/machined(steel bed plate, XY rail mounting tubing, X rail plates, Z plate). This was a kit and is partially assembled with no time to get around to finish it. Most of the uneven powder coating was stripped and added a layer of thin rust prevention paint over the raw steel. Shimming still has to be done on a couple of the axis(shim pack included). Everything that came with the kit is included. Let me know if you have any questions or need clarification. There is also an active DMC2 Facebook community with over 500+ members from all over the world and all different levels of experience. 14? X Axis, 10? Y Axis, 6.5? Z Axis. Approximately 21? Wide x 22? Long x 35? Tall, not including the extra 3 for motors. Approximately 180 lbs, without accessories. Up to 9000mm/min [350 inches/min]. Machine Resolution (Varies with Microstepping Settings). 0.0014mm [0.000055 inches]. Generally final part tolerances are within or below 0.01mm on a well built machine. This is with careful finishing passes on parts, after the heavy roughing cuts. 3 HP (2.2kw), 24000 RPM with built in ER20 Collet. 120V AC 60Hz, or 220V AC 50/60Hz You must specify your desired voltage when you add a machine to your cart. Closed loop motors for all axes with stall/crash detection X, Y and Z automatic probing. Central lubrication system and hand pump for all rails and ball screws. High pressure (40 psi) coolant pump with increased variable flow rate. Chip management and filtration (internal chip tray). Frame specifically designed with spray foam points (for quieter operation). Multi axis MPG handwheel available. DMC2 machines all come with a Mach3 controller board and configuration files only for Mach3. You will need your own CAM software to generate g-code files, such as Autodesk Fusion360 which is available for free. The Mach3 controller included can be easily removed and swapped out for another controller of your choice, such as a LinuxCNC controller or GRBL, as long as they can output standard step, direction, enable signals etc. A Informative Note about Tolerances and Accuracy: Under heavy load, tolerances will slightly drop. This is because the DMC2 uses stepper motors operating as servos. Servo motors attempt to go to their desired position, and if there is some deviation detected, they will dump more current into the motors to overcome the load to reach that desired position. This means that there is always a tiny threshold of allowable error before the servo driver triggers an alarm, and under very fast operation the servo may be trying to go to a new position before the last position was even successfully reached. It is good practice to always follow up roughing cuts with a careful, slow, low force finishing pass to get the best final part dimensions. See our YouTube videos for examples.