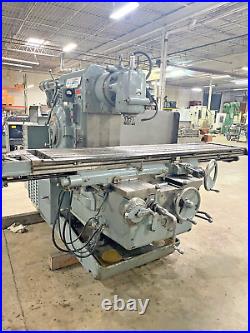

Welcome to Select Machine Tool. Southwestern Trak DPM5 CNC Vertical Bed Mill 50″ x 12″ SM Control. Trak DPM5 Rigid Bed CNC Milling Machine With Proto Trak SM-3 CNC Control, S/N 043AS13013, 2004 Year, Item 06000. STANDARD EQUIPMENT & FEATURES. CNC Controlled Ram Motion. Use As SM-2 Or SM-3. Solid Ram Construction For Rigidity. Ram Is Counterbalanced For Easy Positioning. Large Quill Diameter 3.930. Precision Ground Ball Screws. Ways Are Hardened & Ground With Turcite. Servo Motors With High Resolution Encoders. Graphics Let You See Your Part Before Machining. Program Part Geometry, Tool Path Is Generated Automatically. Heavy Table Loads 1,320 lbs. SPECIFICATIONS OF MILLING MACHINE. SPECIFICATIONS OF MILLING MACHINE: CONT. Net Weight Of Machine. FEATURES OF SM-3 CONTROL HARDWARE. Pentium Processor With Built-In Video and Ethernet Cards. 32 MB of Ram With Expansion Slots Available. Teac Floppy Disk Drive. Ports and Connectors: P/S 2 Keyboard and Mouse, RS232, RJ45. 10.4 Color Active-Matrix Display. Override of Programmed Feedrate and Rapid With Graphical Indicator. Polycarbonate Sealed Membrane with LED Status Lights. Servo Motors 280 in-oz Torque. FEATURES OF SM-3 SOFTWARE. Auto Geometry Engine Makes Calculations For You While You Program. Automatic Diameter Cutter Compensation. Two Axis Circular Interpolation. Look – Program Graphics With A Single Button Push. Six Modes of Operation. Color Graphics With Adjustable Views. Tool Length Offset With Modifiers. Jog and Powerfeed in DRO Mode. Automatic Return to ABS Zero. Incremental and Absolute Position Readout. Inch / MM Selectable. FEATURES OF SM-3 SOFTWARE CONT. Teach – In Of Manual Moves. Scaling Of Print Data. Selectable Tool Path or Part Geometry Programming. Convenient Canned Cycles For All Geometry. Circular, Rectangle or Irregular Pockets, Islands, and Profiles. Helix and Thread Milling Routines. Subroutine and Copy of Programmed Events Displayed. Mirror With Selectable Cutting Order. List Step – Graphics with Programmed Events. Conrad – One Input For Automatic Corner Radius. Incremental and Absolute Programming. Math Helps With Prompted, Graphical Interface. Tool Stepover Adjustable For Pocket Routines. Selectable Ramp Or Plunge Cutter Entry. Clipboard to Copy Events Between Programs. Real Time Run Graphics With Tool Icon. Access to Networked Devices. Automatic File Back Up Routine. We want you to be happy and we also want to help you in any way possible. We want to build relationships with our customers and the best way to do that is by providing quality products, honest representations, value, and service. Again, we want to thank you for your time and interest and we look forward to earning your business in the near future. Thank You for stopping by and please view our other items. FOR ALL OF YOUR AIR, TOOLING, AND MACHINING NEEDS.