2016

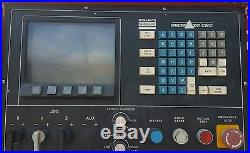

Milling Machine CNC, Dynapath 20 control, Vertical Machine Tree Mill, power knee

Tree Machine Tool Company model Journeyman 325, very likely, one of the best made knee machines ever, certainly one of the most expensive knee Mills ever built during its time. This is a pure bread Dynapath system 20 not an auto con{generally light gray in color}. I had a system 20 auto con and I did not like it, I know people say it’s the same but I can tell you from experience there is a massive difference in the one that I had and the two purebred Dynapath 20{black in color}. First I never had the first second of trouble with either the five, 10, 20, but I did have all sorts of issues to numerous to mention with the generic version called auto con {light gray in color}. And I’m not the only one that has said that but that’s solely my opinion. A little ditty/piece of information. When I had my machine shop in the very beginning, 75% of what I did was grinding of all nature, surface, ID grinding, OD grinding etc. Back then I got a job from Reynolds Metal out of Richmond Virginia, that required a circle, be machined or ground, roughly 11.125 inches diameter plus. 2 inches deep into the plate. When I wrote the operation sheet, I had planned on grinding this dimension with my ID grinder, but when I checked the part with a Bore with the Dial indicator Bore gages, I could find no out of roundness, at any point. So I simply eliminated the grinding operation and Milled the circle to size. There were 55 parts, and I was expecting some problems I actually made three spare parts, Reynolds Metal, bought all 58 parts. I did this on my earlier version Dynapath 10. So imagine just what you can do with this newer version, CNC Dynapath 20 Control. The tool offsets can be set by simply, putting in the tool touching off on your plate using a piece of notebook paper, watch the paper sticks, push the button Tool Cal, and guess what, that tool offset has now been entered into the offset. I’ve owned the Bendix 5, the next version, which to my understanding was a newly formed company and they changed their name to Dynapath controls. I was extremely happy, with the Dynapath 10. So when the newer Dynapath 20 controls, came along, I ordered the upgrade also and I had a Dynapath 20 Lathe Controls.. The only problem I ever had the entire time I owned all 3 pieces of equipment, we were peck drilling 102 holes in one particular cast part, roughly 4 1/4 inches deep{and we had over 2600 castings} over three-year period and then one morning, the Z motor/drive gave out. Three milling machines , that I owned, +1 Lathe had a Dynapath 20, I never express any downtime. It is an extremely reliable control. A recent sale of a Hurco bed machine, we used for quite some time. And now the customer is using, and doing so happily and finding the control easy to utilize and program, we even have a video on how to write the programs, maybe we could make some copies. PS: at the present time, we are. The approximate weight is 3,900 pounds. 75 a mile and you have to add in all the fuel, plus drive the truck yourself, going and coming home…… I believe the above calculations are in the ballpark. So you can see where cheaper than doing it yourself. But you certainly have the option. Please understand, we will not deliver in any kind of implement whether like heavy rains, snow or ice. Generally speaking we prefer to deliver Friday evening over the weekend to your location. Or come pick it up , and pay cash. Cash is not a cashiers check, but green bills, with pictures of dead presidents on them. Respectfully Larry and Pam. PS: at the present time, we are NOT!! The item “Milling Machine CNC, Dynapath 20 control, Vertical Machine Tree Mill, power knee” is in sale since Tuesday, April 26, 2016. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “pamelaann1969″ and is located in Martinsville, Virginia. This item can be shipped to United States.

Comments Off