2023

Fanuc Robodrill 5X a-D21MiB5 CNC Vertical Mill low Hours 5 Axis

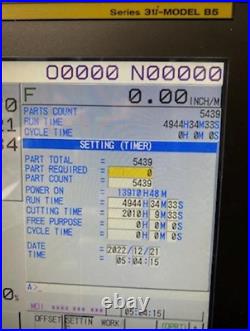

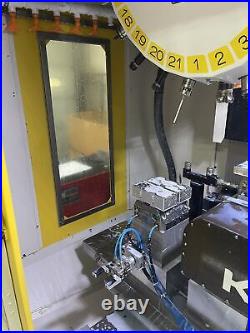

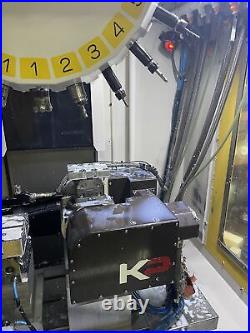

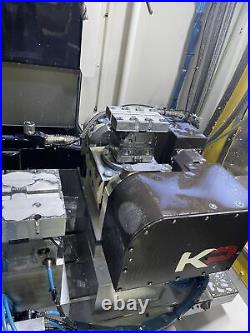

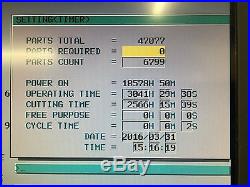

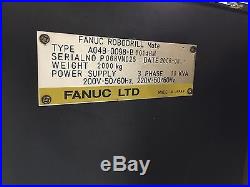

Fanuc Robodrill 5X a-D21MiB5 CNC Vertical Mill low Hours 5 Axis. The machine has a custom washdown coolant system on it ran by an M Code to turn it on and off. It has a custom air blast system that is also ran from an M Code. The Chip conveyor has been customized to run off an M Code as well. The machine is technically a 2018 Machine, but it was on the dealer’s floor as a show model until it was installed in my shop in 2020. The machine has run great. We did a wellness check on the machine during a routine maintenance call and it was perfect. They did check the spindle and it was as good as new. We don’t run the spindle over 20,000 RPM. It has 1,000PSI Thru Spindle Coolant, A Renishaw NC4 Laser Tool setter and a spindle Probe. · Axis Travel of 19.68″ (X Axis), 15.74″ (Y Axis), and 12.9 (Z Axis). · 25.6″ X 15.74″ Table Area With A 660 Lbs Load Capacity. · 200-24,000 RPM Direct Drive High Torque Spindle. · 200L Coolant Tank. · BT-30 Spindle Taper with “Big Plus” Dual Contact Spindle (four bearing design). · 21 Position, Bi-Directional Tool Changer. · “Quick” ATC Recovery System. · 1.6 Second Tool Change Time (Chip to Chip). · 0.9 Second Tool Change Time (Tool to Tool). · 5,000,000 Duty Cycle Time. · Rigid Tapping up to 8,000 RPM. · “Quick” Tap Recovery System. · High Speed Reverse Tapping. · Helical and Linear Interpolation. · 1 Millisecond Servo Response Time. · Three Axis Simultaneous expandable to Five Axis Simultaneous. · Simultaneous ATC / Table Positioning. · 2125 IPM Rapid Rate – X, Y, Z Axis. · Feed Rates to 1181 IPM X, Y, Z. · Multi Step Skip. · AI Contour Control I. · Nano CNC System. · Ultra Precise 32,000,000 Pulses/Rev encoders. · 1.5 G Acceleration. · Thermal Growth Compensation. · 2 MB Memory. · 1,000 Registerable Programs. AD21MiB5 24,000 RPM. CNC Vertical Machining Center. · Smart Backlash Compensation. · Tool Compensation Memory C. · Tool Offset Pairs 200 Pairs. · Part Program Storage 2 MB. · 6 + 48 Work Offsets. · Coordinate System Rotation G68. · Coordinate System Setting (G92). · Custom Macro B. · Canned cycles for drilling (G73, G74, G81G89/G80). · Manual Handle Feed. · Coolant System- 200 liter coolant tank and Spindle Coolant Nozzle. · Skip Function (G31). · Dynamic Graphic Display. · On Screen Display of Spindle’ RPM’ and’Load’ Meters including cutting time count down. · Basic Metal Top Cover. · Leveling Bolts and Pads. · Alpha Numeric Keyboard. · Automatic Lubrication System. · Quick Side (Operator Interface). · Manual Guide for Milling (Shop Floor Programming System). · Manuals (1) Each: Operators, Maintenance, Parts, Operators CNC. · MistBuster Mist Collector. · Interior Work Light – LED STYLE. Qty 1: D21MiB5-24K-STD-F001 RoboDrill Medium 21 ATC 24k RPM. Qty 1: MMT-28293 Tsudakoma TWA-130 4th and 5th Axis Rotary Table. Qty 1: MMT-24564 Column Riser. Qty 1: MMT-28207 CTS High pressure coolant thru spindle. Qty 1 MMT-25726 Fanuc Robodrill High Speed package B, High speed. Package Includes below 10 line items. AI CC II 200 Block Look Ahead 31iB5. High Speed Process 31iB5. 1000 Block Lookahead 31iB5. Rotary Table Dynamic Fix Offset 3IiB5. Tool Center Point Control 5Axis 31iB5. 3D Cutter Comp 31iB5. Tilted Working Plane Command 31iB5. Data Server Function 31iB5 Fast Ethernet/Dataserver 4GB 31iB5. Qty 1: CC-57008058 LNS-Turbo Chip conveyor LH/RH Side Discharge. MicroHinge 500, 227 liter / 60 gallon tank. Qty 1: MMT-25031 Renishaw OMP 40 In Process Measurement Optical Probe. Qty 1: MMT-24616 Renishaw NC4 Laser Tool Setter. If you have any question let me know. Four three five seven six zero three six eight six. Or send me a message. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “racetunediesel” and is located in this country: US. This item can be shipped to United States.

- Model: Robodrill 5X a-D21MiB5

- Brand: FANUC

- Function: Milling

- Control: CNC

- Model Year: Unknown

- Machine Type: Vertical Milling Machine

Comments Off