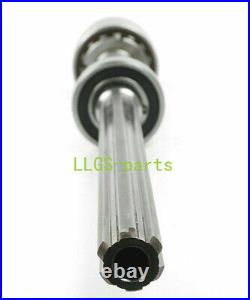

Mill Machine Parts R8 Spindle + Bearings Assembly Fit BRIDGEPORT Milling US Product description: This product is a high quality R8 spindle + bearing for 3#4# milling machine. After the spindle is replaced, it can change the surface or side of the milling workpiece caused by the tool wear caused by the long wear of the spindle and the bearing clearance. Smooth, rough and uneven! Product specifications: Name: Milling R8 spindle + bearing Total length of the spindle: 545mm Head outer diameter: 46mm Spline outer diameter: 25mm D:25mm D1:20mm B:5mm Bearing position: 35mm and 30mm Packing size: 561010cm Weight: 4.2kg Scope of application: Most milling machines (3#4# milling machine) The package includes: 1X R8 spindle + bearing. Milling Machine Parts R8 Spindle + Bearings Assembly for. Mill Machine Parts R8 Spindle + Bearings Assembly Fit BRIDGEPORT Milling. This product is a high quality R8 spindle + bearing for 3#4# milling machine. Name: Milling R8 spindle + bearing. Total length of the spindle: 545mm. Head outer diameter: 46mm. Spline outer diameter: 25mm. Bearing position: 35mm and 30mm. Scope of application: Most milling machines (3#4# milling machine). 1X R8 spindle + bearing. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Do not send to Brazil. Creative Design, Durable Material, Beautiful Appearance. Milling R8 spindle + bearing. Total length of the spindle. Most milling machines (3#4# milling machine).