2025

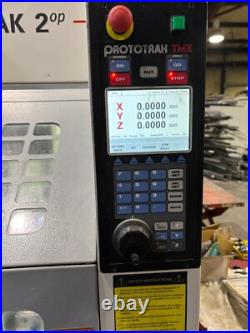

Southwestern industies X axis Servo MOTOR proto trak SWI

COMPLETE UNIT MOTOR BRACKETS AND ENCODER.

Comments Off

COMPLETE UNIT MOTOR BRACKETS AND ENCODER.

Comments Off

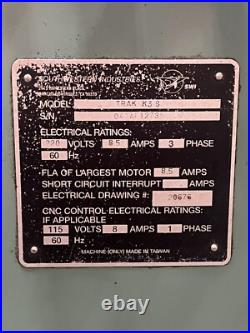

Nice fully functional mill that can be used as a manual machine or with the CNC control in X & Y. The table and ways are all in good shape with no damage or scarring. Southwestern Industries Trak K3 2-axis CNC Knee Mill. 3HP 230/460 3-phase motor. Proto Trak Edge CNC controller. 10″ x 50″ table. DRO for all 3 axis. Kurt power draw bar. Located in Peoria, AZ. If you are nearby and wish to pick it up I have a forklift to load.

Comments Off

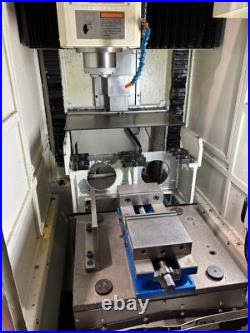

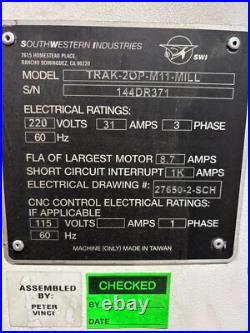

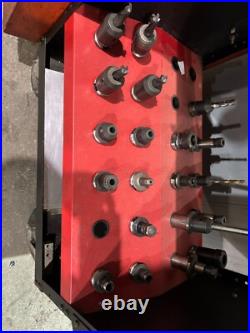

This is a Southwestern Industries CNC Vertical Machining Center with an 8 tool automatic tool changer. The Machine uses BT30 toolholders and this unit comes with a tooling cart and 59 toolholders. It also comes with a pallet jack to move it around. We bought this machine new in 2015, mainly to make small, end of arm, gripper tooling. The machine is under power and can be inspected if you are in the Kansas City area. Comes with operating manual, Kurt Vise, 2 tooling plates and the above mentioned tooling cart. The mill itself weighs 2,825 pounds. Size is 36″ W x 64″ L x 94 H. If you can get to the Kansas City area, we will load you out for free. Would prefer to be paid by check or wire transfer.

Comments Off

Power Drawbars to fit Southwestern Industries K2, K3 Knee mills with R-8 spindles. Drawbars for other models are available upon request. Send us a message. All Sales are Final.

Comments Off

Welcome to Select Machine Tool. SOUTHWESTERN INDUSTRIES Trak DPM Rigid Bed CNC Milling Machine With Proto Trak SMX-3 CNC Control. Can Also Be Used As A Manual Mill With 3 Axis DRO, Power Feed, & Jog Capabilities, Item No. 071CF15369, 2007 Year Model. Table Size – 50″ x 10″. T-Slots (number x width x pitch) – 3 x. 63″ x 2.48″. Travel (X, Y, Z axis) – 31.5 x 17 x 23.5. Quill Diameter – 4 1/8. Maximum Quill Travel – 5. Spindle Taper – NMTB 40. Spindle Speed Range RPM – Varispeed drive – 70-3950. Spindle Center to Column Face – 19. Spindle Motor Power – vari-speed head – 5 HP. Power requirements, control – 110V; 1P; 8A. Power requirements, machine with vari-speed head – 220/440V;3P; 14/7A. Maximum Weight of Workpiece – 1320 lbs. Height of table from bottom of bed – 38. Max spindle nose to table – 23.5. Min height – 85. Max height – 95. Width of machine including table – 73. Length with electric box door closed – 60. Overall width incl full table traverse – 108. Overall length with electrical door open – 70. Footprint of Machine – 24″ x 44″. 4100 / 4400. Rapid traverse X, Y, Z – 150 IPM. Precision ground ballscrews in the table, saddle and ram. Chrome hardened and ground quill. Slide ways are Turcite coated. Wide way surfaces are hardened and ground. Drilling max capacity, Varispeed head- 1 dia. Milling max capacity, Varispeed head – 5 inch3/min. Tapping max capacity, Varispeed head – 1. ProtoTRAK SMX System Specifications. Two- or three-axis CNC, 3-axis DRO. Real handwheels for manual operation. 10.4 color active-matrix screen. P/S 2 Keyboard connector. Override of program feedrate. LED status lights built into display. Uncluttered front panel with few hard keys. Integrated Ram and Quill encoders resolve to one Z dimension. Software Features – General Operation. Clear, uncluttered screen display. English language – no codes. Soft keys – change within context. Selectable two or three-axis CNC. Color graphics with adjustable views. Convenient modes of operation. Incremental and absolute dimensions. Jog at rapid with override. Powerfeed X, Y or Z. Do One CNC canned cycle. Teach-in of manual moves. Servo return to 0 absolute. Tool offsets from library. Scaling of print data. Three-axis Geometry conversational programming. Automatic diameter cutter comp. Look -graphics with a single button push. List step – graphics with programmed events displayed. Conrad – automatic corner radius. Math helps with graphical interface. Auto load of math solutions. Tool step over adjustable for pocket routines. Pocket bottom finish pass. Selectable ramp or plunge cutter entry. Subroutine repeat of programmed events. Rotate about Z axis for skewing data. Mirror of programmed events. Clipboard to copy events between programs. Set Up Mode Features. Tool length offset with modifiers. Tool path graphics with adjustable views. Program run time estimation clock. Trial run at rapid. 3D CAM file program run. 3D G code file run with tool comp. Real time run graphics with tool icon. Program In/Out Mode Features. Simple program storage to floppy. Converter for prior-generation ProtoTRAK programs. Auto Geometry Engine T. Countdown clock to next pause or tool change. Total program time estimator. Tool path conversational programming. Copy with or without offsets. Copy Rotate, Copy Mirror. We want you to be happy and we also want to help you in any way possible. We want to build relationships with our customers and the best way to do that is by providing quality products, honest representations, value, and service. Again, we want to thank you for your time and interest and we look forward to earning your business in the near future. Thank You for stopping by and please view our other items. FOR ALL OF YOUR AIR, TOOLING, AND MACHINING NEEDS.

Comments Off

Welcome to Select Machine Tool. Southwestern Trak DPM5 CNC Vertical Bed Mill 50″ x 12″ SM Control. Trak DPM5 Rigid Bed CNC Milling Machine With Proto Trak SM-3 CNC Control, S/N 043AS13013, 2004 Year, Item 06000. STANDARD EQUIPMENT & FEATURES. CNC Controlled Ram Motion. Use As SM-2 Or SM-3. Solid Ram Construction For Rigidity. Ram Is Counterbalanced For Easy Positioning. Large Quill Diameter 3.930. Precision Ground Ball Screws. Ways Are Hardened & Ground With Turcite. Servo Motors With High Resolution Encoders. Graphics Let You See Your Part Before Machining. Program Part Geometry, Tool Path Is Generated Automatically. Heavy Table Loads 1,320 lbs. SPECIFICATIONS OF MILLING MACHINE. SPECIFICATIONS OF MILLING MACHINE: CONT. Net Weight Of Machine. FEATURES OF SM-3 CONTROL HARDWARE. Pentium Processor With Built-In Video and Ethernet Cards. 32 MB of Ram With Expansion Slots Available. Teac Floppy Disk Drive. Ports and Connectors: P/S 2 Keyboard and Mouse, RS232, RJ45. 10.4 Color Active-Matrix Display. Override of Programmed Feedrate and Rapid With Graphical Indicator. Polycarbonate Sealed Membrane with LED Status Lights. Servo Motors 280 in-oz Torque. FEATURES OF SM-3 SOFTWARE. Auto Geometry Engine Makes Calculations For You While You Program. Automatic Diameter Cutter Compensation. Two Axis Circular Interpolation. Look – Program Graphics With A Single Button Push. Six Modes of Operation. Color Graphics With Adjustable Views. Tool Length Offset With Modifiers. Jog and Powerfeed in DRO Mode. Automatic Return to ABS Zero. Incremental and Absolute Position Readout. Inch / MM Selectable. FEATURES OF SM-3 SOFTWARE CONT. Teach – In Of Manual Moves. Scaling Of Print Data. Selectable Tool Path or Part Geometry Programming. Convenient Canned Cycles For All Geometry. Circular, Rectangle or Irregular Pockets, Islands, and Profiles. Helix and Thread Milling Routines. Subroutine and Copy of Programmed Events Displayed. Mirror With Selectable Cutting Order. List Step – Graphics with Programmed Events. Conrad – One Input For Automatic Corner Radius. Incremental and Absolute Programming. Math Helps With Prompted, Graphical Interface. Tool Stepover Adjustable For Pocket Routines. Selectable Ramp Or Plunge Cutter Entry. Clipboard to Copy Events Between Programs. Real Time Run Graphics With Tool Icon. Access to Networked Devices. Automatic File Back Up Routine. We want you to be happy and we also want to help you in any way possible. We want to build relationships with our customers and the best way to do that is by providing quality products, honest representations, value, and service. Again, we want to thank you for your time and interest and we look forward to earning your business in the near future. Thank You for stopping by and please view our other items. FOR ALL OF YOUR AIR, TOOLING, AND MACHINING NEEDS.

Comments Off

Power Drawbars to fit Southwestern Industries Prototrak Bed Mills. Fits DPMSX3, DPMSX5, DPMRX3, DPMRX5 and K4 with serial #’s with CF, CS, DL and AC. Drawbars for other models are available upon request. Send us a message. All Sales are Final.

Comments Off

Southwestern Industries TRAK DPM CNC Vertical Bed Mill. Located in a Connecticut shop, under power. Feel free to inspect under power. I have a video of it running. Serious inquires only please. A rigger is required to remove and load. Capital Machine Tools Fairfield CT.

Comments Off

/ Template: Frooition Description: Version: 1.2 /. CNC Vertical Machining Centers. America’s Premier Machine Tool Dealer. Providing Quality Machining and Fabrication Machinery Solutions. Air Cooling & Heating Equip. Chemical & Processing Equip. Cleaning, Painting, & Washing. CNC Horizontal Machining Ctrs. Electrical and Power Equipment. Glass and Window Machinery. Inspection & Measuring Equip. Paper & Printing Equipment. Tube and Pipe Machinery. Add to Favorite Sellers. Sign up to Newsletter. Southwestern Industries Trak K3SX-3 ProtoTrak SMX 3-Axis CNC Vertical Milling Machine. 6′ L x 7′ W x 8′ H. 60 – 4200 RPM. 220V/3PH(Motor Head), 115V/1PH(Controller). Southwestern Industries ProtoTrak SMX 3-Axis CNC Controller (2012). The Southwestern Industries CNC Milling Machine can be demoed upon request. Check out the video on the listing to see it in operation. Video will open in a new window. The Equipment Hub is a used machinery dealer and auctioneer that provides superior industrial equipment solutions to manufacturers throughout the world. We operate in a 40,000-square-foot warehouse and showroom located in Stone Mountain, Georgia with satellite offices located in Florida, North Carolina, and Texas. Established in December 2011, our core belief is that superior customer service is of paramount importance to the success of our company and yours. As proud members of the MDNA (Machinery Dealers National Association) we back up our core belief by providing 30-day MDNA return privileges on most of the machinery we sell. The Equipment Hub provides various services to help manufacturers achieve their machinery goals. We look forward to doing business with you and becoming a lifelong business partner. If you prefer to set up your own trucking we will place the item on a standard pallet with metal banding. If you need a custom pallet or skid built we can direct you toward local companies that provide these services. S place of business, unless otherwise specified on the accompanying “quote/invoice” form. The Equipment Hub SHALL NOT BE RESPONSIBLE FOR THE CONSEQUENCES OF PURCHASER’S FAILURE TO INSPECT THE EQUIPMENT OR MERCHANDISE OR FOR ANY INACCURACIES, INSUFFICIENCIES, OR OMISSIONS IN SUCH DESCRIPTIONS, SAMPLES, TOLERANCES AND/OR SPECIFICATIONS. The employees or representatives of The Equipment Hub are not authorized to make any statement or representation as to the quality, character, size, condition, quantity, etc. Of the equipment and merchandise offered for sale inconsistent with these Terms and Conditions. Any such statements made will not be binding on The Equipment Hub or be grounds for any subsequent claim. STORAGE: The Equipment Hub will provide up to 30 days of free storage, unless otherwise specified on the accompanying “quote/invoice” form. Basis or brokered bears a thirty day return privilege. All implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed and excluded from this agreement. Care is taken to give reliable descriptions but these are not guaranteed and prospective purchasers are advised to check vital details. We also reserve the right to correct any stenographic errors. All specifications and descriptions of said goods are approximate only. THE WARRANTIES DISCLAIMED HEREUNDER INCLUDE, BUT ARE NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No salesman or other representative of The Equipment Hub has authority to make any warranties. It is Purchaser’s responsibility to inspect the goods and to ascertain if the specifications, tolerances, descriptions and condition of the goods conform to the Purchaser’s requirements. Purchaser does hereby discharge The Equipment Hub from any and all liability directly or indirectly resulting from the presence of the aforesaid chemicals or materials, including and not limited to any and all liability directly or indirectly resulting from the failure of The Equipment Hub to give more specific warning with respect to individual articles or substances or from the inadequacy of any warning. Suggestions by The Equipment Hub regarding the design, specification, tolerances, use or suitability of the Products are made in good faith but are not binding upon any party and do not give rise to any liability by The Equipment Hub. MODIFICATIONS/ SEVERABILITY: Purchaser acknowledges that these are the only Terms and Conditions of sale, and is intended by the parties as a complete and exclusive statement of the terms of their agreement. This supersedes all prior agreements, written or oral. Any variation from the terms hereof contained in the Purchaser’s acceptance is hereby rejected. The agreement of which these terms are a part can be modified or rescinded only in writing signed by The Equipment Hub. If any provision of the invoice or these Terms and Conditions is determined illegal or unenforceable, it shall not affect the enforceability of any other provision or paragraph of the invoice or these Terms and Conditions. The remedy hereby provided shall be the exclusive and sole remedy of Purchaser and any right to consequential and incidental damages is excluded. You May Also Like. View more great items. Jet JTM-1055 10″ x 54″ Vertical Milling Machine w/ Acu-Rite DRO, (3) Power Feeds. $6,950.00. Acra LCTM1 3 Axis CNC 10″ x 50″ Knee Mill. $33,250.00. Bridgeport M Head 9″ x 32″ Vertical Milling Machine w/ Pneumatic Indexing Tab.. $2,450.00. Shop Popular Used Machinery Categories. This listing is currently undergoing maintenance, we apologise for any inconvenience caused.

Comments Off

Ia have a dmp trak iam stripping down for parts what i have is good used spindle we have to remove, this is a stock photo. Will include bearings with spindle if you need quill we can include same price.

Comments Off