2024

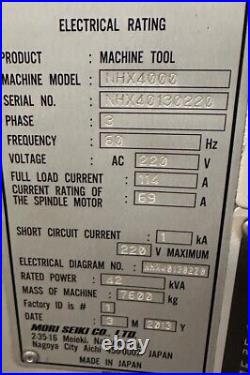

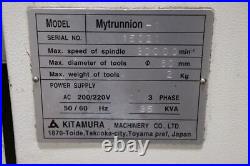

Kitamura Mytrunnion-1 5-Axis VMC Vertical Machining Center

/ Template: Frooition Description: Version: 1.2 /. CNC Vertical Machining Centers. America’s Premier Machine Tool Dealer. Providing Quality Machining and Fabrication Machinery Solutions. Air Cooling & Heating Equip. Chemical & Processing Equip. Cleaning, Painting, & Washing. CNC Horizontal Machining Ctrs. Electrical and Power Equipment. Glass and Window Machinery. Inspection & Measuring Equip. Paper & Printing Equipment. Tube and Pipe Machinery. Add to Favorite Sellers. Sign up to Newsletter. Kitamura Mytrunnion-1 5-Axis VMC Vertical Machining Center. 17′ L x 8′ W x 10′ H. Fanuc Series 300i-Model A CNC Controller, Coolant System, Chip Conveyor. The Kitamura VMC can be demoed upon request. Check out the video on the listing to see it in operation. Video will open in a new window. The Equipment Hub is a used machinery dealer and auctioneer that provides superior industrial equipment solutions to manufacturers throughout the world. We operate in a 40,000-square-foot warehouse and showroom located in Stone Mountain, Georgia with satellite offices located in Florida, North Carolina, and Texas. Established in December 2011, our core belief is that superior customer service is of paramount importance to the success of our company and yours. As proud members of the MDNA (Machinery Dealers National Association) we back up our core belief by providing 30-day MDNA return privileges on most of the machinery we sell. The Equipment Hub provides various services to help manufacturers achieve their machinery goals. We look forward to doing business with you and becoming a lifelong business partner. If you prefer to set up your own trucking we will place the item on a standard pallet with metal banding. If you need a custom pallet or skid built we can direct you toward local companies that provide these services. S place of business, unless otherwise specified on the accompanying “quote/invoice” form. The Equipment Hub SHALL NOT BE RESPONSIBLE FOR THE CONSEQUENCES OF PURCHASER’S FAILURE TO INSPECT THE EQUIPMENT OR MERCHANDISE OR FOR ANY INACCURACIES, INSUFFICIENCIES, OR OMISSIONS IN SUCH DESCRIPTIONS, SAMPLES, TOLERANCES AND/OR SPECIFICATIONS. The employees or representatives of The Equipment Hub are not authorized to make any statement or representation as to the quality, character, size, condition, quantity, etc. Of the equipment and merchandise offered for sale inconsistent with these Terms and Conditions. Any such statements made will not be binding on The Equipment Hub or be grounds for any subsequent claim. STORAGE: The Equipment Hub will provide up to 30 days of free storage, unless otherwise specified on the accompanying “quote/invoice” form. Basis or brokered bears a thirty day return privilege. All implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed and excluded from this agreement. Care is taken to give reliable descriptions but these are not guaranteed and prospective purchasers are advised to check vital details. We also reserve the right to correct any stenographic errors. All specifications and descriptions of said goods are approximate only. THE WARRANTIES DISCLAIMED HEREUNDER INCLUDE, BUT ARE NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No salesman or other representative of The Equipment Hub has authority to make any warranties. It is Purchaser’s responsibility to inspect the goods and to ascertain if the specifications, tolerances, descriptions and condition of the goods conform to the Purchaser’s requirements. Purchaser does hereby discharge The Equipment Hub from any and all liability directly or indirectly resulting from the presence of the aforesaid chemicals or materials, including and not limited to any and all liability directly or indirectly resulting from the failure of The Equipment Hub to give more specific warning with respect to individual articles or substances or from the inadequacy of any warning. Suggestions by The Equipment Hub regarding the design, specification, tolerances, use or suitability of the Products are made in good faith but are not binding upon any party and do not give rise to any liability by The Equipment Hub. MODIFICATIONS/ SEVERABILITY: Purchaser acknowledges that these are the only Terms and Conditions of sale, and is intended by the parties as a complete and exclusive statement of the terms of their agreement. This supersedes all prior agreements, written or oral. Any variation from the terms hereof contained in the Purchaser’s acceptance is hereby rejected. The agreement of which these terms are a part can be modified or rescinded only in writing signed by The Equipment Hub. If any provision of the invoice or these Terms and Conditions is determined illegal or unenforceable, it shall not affect the enforceability of any other provision or paragraph of the invoice or these Terms and Conditions. The remedy hereby provided shall be the exclusive and sole remedy of Purchaser and any right to consequential and incidental damages is excluded. You May Also Like. View more great items. Mazak Nexus VCN 510C-II Vertical Machining Center. $49,500.00. Fadal VMC4020HT CNC Vertical Machining Center w/4th Axis. $19,500.00. Doosan DNM 500II CNC Vertical Machining Center w/ 4th Axis. $57,500.00. Northwood FA294FT 5 Axis CNC Vertical Machining Center. $325,000.00. Shop Popular Used Machinery Categories. This listing is currently undergoing maintenance, we apologise for any inconvenience caused.

Comments Off