2023

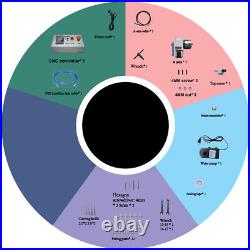

3/4 Axis 6090 3040 6040 CNC Router Engraver Milling Drilling? 3D Cutter USB NEW

3/4 Axis 6090 3040 6040 CNC Router Engraver Milling Drilling? 3D Cutter USB NEW. Model One:usb 4 Axis Cnc 6090 Router 2200w. Cnc 6090 Router 4axis+2.2kw Spindle Motor +Vfd +Usb Port Metal Wood engraver with. Cnc Router Engraving Machine Parameters. Outside Dimension:1150x970x650mm(Lxwxh). Working Platform Size:1045x720mm(Lxw). Frame Material:the Whole Machine Used 6061 Aluminum Profiles. Feeding Height:? 140mm(from Base of Z Axis to Platform). X, Y, Z Working Area:600x900x150mm. Sliding Unit:x Axis:sfu1605 Ball Screws;Y Axis:sfu1605 Ball Screws;Z Axis:sfu1204 Ball Screws. Drive Unit:x Axis:ø20 High Intensity Round Rail, Y Axis: Sbrø20 High-strength Aluminum Base Rails;Z Axis: ø12 High-strength Round Rail. Stepping Motor:two-phase 3a (with Handwheels). Driving Power for Stepping Motor:ac110,240w, Output Dc24v10a. Maximum Idle Speed:1500mm/M. Working Speed:50-1500mm/Min (Different Material with Different Speed Settings). Spindle Motor:2200whigh-speed Variable Frequency Spindle Motor, Er11 Chuck, Matching 6mm Bur. Variable-frequency Drive(Vfd):Ac110v, 2200w, 0-400hz(Built-in Control Box). Tips:1, the Spindle Motor Must Connect with the Vfd. 2, It Cannot Directly Connect with the Supply Voltage (Ac110v/220v). 3, Please Don’t Change the Data Setting of the Vfd If You Are Not Professional Technicians, or It Might Damage the Spindle Motor. Drive of Stepping Motor. 0-3.5a Adjustable Four-axis DriveTb6560ahqchip, 24v Power Supply, 2,4,8,16subdivision. Settings, Factory Setting:8subdivided. Repositioning Precision:? 0.05mm. Cooling Method:water Cooling, Matching Heat Dissipation Water Pump. Spindle Precision:radial Runout? 0.03mm. Carving Command:g Code/Tab File/Nc/Tab /Ncc/File. Protection:emergency Stop Button. Communication Interface:through Usb Port Connect with Computer. Support System:windows Xp / Win7 with 32bite. Gross Weight of Machine. Update Function: with Limit Switch. Woodworking Industry: Sculpture, Round Carving, Wooden Handicraft Processing. Advertising Signs: Logo Making, Cutting Acrylic, Plastic Molding, Suit for Making a Variety of Materials Advertising Decorative Products. Other Industries: the Engraver Could Do Shadow-carved, Sculpture Which Widely Used in the Gift Industry; Can Be Used in Aluminum Cutting Industry, Such As Aluminum, Aluminum-plastic Plate, Aluminum Honeycomb Panels, Aluminum, 3d Engraving Process, Artificial Plate, Cutting Led and Neon Letter, Making Plastic Light Box Model; Also Can Engrave on Acrylic, Copper, Pvc Board, Artificial Stone, Mdf Board, and Other Metal Sheet. 1, the New 2.2kw Water-cooled Vfd Is Available Operating for Long Time, Which Can Reinforced the Processing Ability of the Machine and Can Be Used to Engrave on Aluminum Alloy and Hard Wood. 2, Water Cooling Spindle Works More Stable and Durable. 3, High Quality Accurate Ball Screws Drive Make the Engrving More Precision. Anti-blackflash, High Precision, Long Life Circle. Assembling and Locating the Cnc Machine on Steady Desk Well. Make Sure That Your Computer Has a Usb Port Output. Place the Control Box in a Ventilated Dry Place Where There Is No Dust, No Moisture. Connecting the Control Box with the Cnc Machine and You Computer and Make Sure the Plug Will Not Come off. Correctly Connect the Machine with the Controller. Don’t Suspended the Cable Which Connect the Spindle Motor with Axis(X, Y, Z, a). Damage the Driver of the Controller. Correctly Instal the Spindle Motor and the Heat Pump. The Heat Pump Should Be Covered Completely in the Water, Then Turned on the Electric Current to. Check Whether the Water-cooling System Working Well. Before Turn on the Machine, Please Check All the Cable and Water- Cooling System to Make Sure They Are Working Fine. You Can Enjoy Making You Dream with Using Our Cnc Machine Now. 1x Main Unit (Frame). 1x Main Unit (Working Base). 1x Sinal Cable for a Axis. 10x 47mm Round Head. 6x 410mm Black Inner Six Angle Screw with Nut. 8x 520mm Black Inner Six Angle Screw. 4x 58mm Flat Philip’s Head Screw with Nut and Gasket. 8x 624mm Balck Flat Inner Six Angle Screw. 2x Six Angle Wrench(3mm). 2x Six Angle Wrench(4mm). 1x Tools Setting Auto-check Instrument for Cnc. Model Two:usb 4 Axis Cnc 6090 Router 1500w. 4axis Usb 1500w Cnc Router Engraving Machine Engraver for Wood Acrylic 6090 Ball Screw. Outside Dimension: 1150970650mm(LWH). Working Platform Size: 1045720mm(LW). X, Y, Z Working Area: 900(Y)600(X)140mm(Z). X Axis:sfu1605 Ball Screws. Y Axis:sfu1605 Ball Screws. Z Axis:sfu1204 Ball Screws. X Axis: ø20 High Intensity Round Rail. Y Axis: Sbrø20 High-strength Aluminum Base Rails. Z Axis: ø12 High-strength Round Rail. Stepping Motor: 57 Two-phase 3a (with Handwheels). Driving Power for Stepping Motor: Ac110, 240w, out Put: Dc24v, 10a. Maximum Idle Speed: 1500mm/Min. Working Speed: 50-1500mm / Min (Different Material with Different Speed Settings). Spindle Motor: 1500w High-speed Variable Frequency Spindle Motor, Er11 Chuck, with 6mm Collet. The Spindle Motor Must Connect with the Vfd. It Cannot Directly Connect with the Supply Voltage (Ac 110v). Please Don’t Change the Data Setting of the Vfd If You Are Not Professional Technicians, or It Might Damage the Spindle Motor. Drive of Stepping Motor: 0-3.5a Adjustable Four-axis Drive. (Tb6560ahq Chip, 24v Power Supply, 2,4,8,16 Subdivision Can Be Set, Factory Settings 8 Subdivision). Spindle Precision: Radial Runout? 0.03mm. Carving Command: G Code / Tab File / Nc File / Ncc File. Vfd: Ac110v, 1500w, 0-400hz (Built-in Control Box). Usb Control Box Parameters. Protection: Emergency Stop Button. Communication Interface: Through Usb Port Connect with Computer. Support System: Windows Xp / Win7 with 32 Bit. Input Volts: Ac 110v. Advertising Industry: Advertising Signs, Logo Making, Cutting Acrylic, Plastic Molding, Suit for Making a Variety of Materials Advertising Decorative Products. The New 1.5kw Water-cooled Vfd Is Available Operating for Long Time, Which Can Reinforced the Processing Ability of the Machine and Can Be Used to Engrave on Aluminum Alloy and Hard Wood. Water Cooling Spindle Works More Stable and Durable. High Quality Accurate Ball Screws Drive Make the Engrving More Precision. Model Three:usb 4 Axis Cnc 6040 Router 1500w. 1x 25pin Parallel Lines. Notes:please Prepare a Computer with Db25 Parallel Interface. Suitable for Pcb, Wood, Plexiglass, Pvc, Crystal Acrylic, Resin, Plastic, Seals, Mdf, Composite. Aluminum Material, Copper, Iron. This Cnc 6040t Machine Is Suitable for Industry, Technology Research, Advertising Design. Arts Creation, Teaching, Student Project and Hobby Purposes. It Can Work with Various Materials(Metallic & Non-metallic), Such As: Wood, Pmma or Other. Plastic, Mdf Board, Native Wood, Pvc, Acrylic, Wood, Composite. Like Aluminum, Copper and Silver to Engrave Them into. It Can Used for Engraving: Advertising Signs, Pcb, Nameplates, Badges, Seals, Bronzing Plate, Aluminum Alloy, Acrylic Plates, Abs Resin Double Color Plate. Pvc Foaming Board, Indentation Plates, Signs, Construction Models, Instrument Panels, Wooden Products, Etc. The Mini Cnc Router Frame Is Movable. The Machine Can Connect with Computer As Other. External Device Such As Printer, Scanner.. With the Assist of the Cnc Router 6040t, Your Design Idea Will Be Real-time Display. Cnc Engraving Machine Parameters. X, Y, Z Working Area : 600(Y)390(X)120(Z)Mm. Lathe Structure : 6061/6063 Aluminum Alloy. X Axis :1605 Ball Screws. Y Axis :1605 Ball Screws. Z Axis:1204 Ball Screws. X Axis:high Intensity Chromeplate Shaft. 1, the Spindle Motor Must Connect with the Vfd. 2, It Cannot Directly Connect with the Supply Voltage (Ac110v). 3, Please Don’t Change the Data Setting of the Vfd If You Are Not Professional Technicians. Or It Might Damage the Spindle Motor. Material:304 Stainless Steel, Copper Coil, Pressure Cast Aluminum Pipe Water Jacket. Ac110v-220v/50hz, 5a, 1.5kw Vfd. Spindle Speed : 24000 Rpm. Max Working Frequency : 400hz. Principal Axis Collet: Er11collet, Standard Configuration :6mm. Speed Mode:by Adjusting the Vfd Output Voltage and Operating Frequency. Lubrication Way: Lubricated by High Grease. Repeat Accuracy:0.05mm. Spindle Precision:radial Beat Acuities 0.03mm. Carving Instructions: G Code / Tab Files / Nc File / Ncc Files. Communication Interface:through Usb Connection with Computer. Support System: Windows Xp Win7. Maximum Idle Speed:1500mm/Min. Working Speed :50-1500mm / Min (Different Material with Different Speed Settings). Control Unit:toroidal Transformer + Pwm Power Supply Module + Tb6560 Stepping Motor Drive. Command Code:g Code. 1, the New 1.5kw Water-cooled Vfd Is Available Operating for Long Time, Which Can Reinforced the Processing Abilty of the Machine and Can Be Used to. Process Aluminum Alloy and Hard Wood. Make Sure That Your Computer Has a 25pin Parallel Port Output. Place the Contral Box in a Ventilated Dry Place Where There Is No Dust, No Moisture. Model Four:usb 3 Axis Cnc 6040 Router 1500w. 3 Axis Cnc Router 6040 Engraver Engraving Mill&Drill 3d. Suitable for Pcb, Wood, Plexi Glass, Pvc, Crystal Acrylic, Resin, Plastic, Seals, Mdf, Composite, Aluminum Material, Copper. This Cnc 6040 Machine Is Suitable for Industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. It Can Work with Various Materials(Metallic & Non-metallic), Such As: Wood, Pmma or Other Plastic, Mdf Board, Native Wood, Pvc, Acrylic, Wood, Composite Board Plywood. Like Aluminum, Copper and Silver to Engrave Them into 3d/2d Works Etc. It Can Used for Engraving: Advertising Signs, Pcb, Nameplates, Badges, Seals, Bronzing Plate, Aluminum Alloy, Acrylic Plates, Abs Resin Doublecolor Plate, Pvc Foaming Board, Indentation Plates, Signs, Construction Models, Instrument Panels, Wooden Products, Etc. The Machine Can Connect with Computer As Other External Device Such As Printer, Scanner.. X, Y, Z Working Area: 600(Y)390(X)120(Z)Mm. Lathe Structure: 6061/6063 Aluminium Alloy. X Axis—1605 Ball Screws. Y Axis—1605 Ball Screws. It Cannot Directly Connect with the Supply Voltage (Ac220v). Material: 304 Stainless Steel, Copper Coil, Pressure Cast Aluminum Pipe Water Jacket. Volts, Current, Power: Ac110 /60hz, 5a, 1.5kw Vfd. Spindle Speed: 24000 Rpm. Max Working Frequency: 60hz. Speed Mode: by Adjusting the Vfd Output Voltage and Operating Frequency from 0-24000rpm. Repeat Accuracy: 0.05mm. Spindle Precision: Radial Beat Acuities 0.03mm. Communication Interface: Through Usb Connection with Computer. Support System: Windows Xp/Win7. Control Unit: Toroidal Transformer + Pwm Power Supply Module + Tb6560 Stepping Motor Drive. Computer Connection: Usb Port. Command Code: G Code. The New 1.5kw Water-cooled Vfd Is Available Operating for Long Time, Which Can Reinforced the Processing Abilty of the Machine and Can Be Used Toprocess Aluminum Alloy and Hard Wood. Otherwise, It Will Damage the Driver of the Controller. The Heat Pump Should Be Covered Completely in the Water, Then Turned on the Electric Current to Check Whether the Water-cooling System Working Well. Before Turn on the Machine, Please Check All the Cable and Water-cooling System to Make Sure They Are Working Fine. If You Have Any Problem. Model Five:usb 4 Axis Cnc 3040 Router 800w. 4axis Cnc Router 3040 Engraver Dril Milling Machine Spindle Motor Vfd Usb. Cnc Router Engraving Machine Engraver 3040 Cool Spindlemotor Vfd 800w Usb Port. X, Y, Z Working Area: 400(Y)295. X Axis—Sfu01204-4 Ball Screws. Y Axis—Sfu01204-4 Ball Screws. Z Axis—Sfu01204-4 Ball Screws. It Cannot Directly Connect with the Supply Voltage (220v). Volts, Current, Power: Ac220v, 50hz, 5a, 0.8kw Vfd. Max Working Frequency: 400hz. Principal Axis Collet: Er11collet, Standard Configuration:6mm. Mode: by Adjusting the Vfd Output Voltage and Operating Frequency from 0-24000rpm. Support System: Windows Xp / Win7,32bits. Carving Speed: 0-2500mm/MinDifferent Materials Differ. 8x 611mm Balck Flat Inner Six Angle Screw. This Cnc 3040t Machine Is Suitable for Industry, Technology Research, Advertising. Design, Arts Creation, Teaching, Student Project and Hobby Purposes. And Soft Metal, like Aluminum, Copper and Silver to Engrave Them into 3d/2d Works Etc. It Can Used for Engraving: Advertising Signs, Pcb, Nameplates, Badges, Seals, Bronzing Plate, Aluminum. Alloy, Acrylic Plates, Abs Resin Double Color Plate, Pvc Foaming Board, Indentation Plates, Signs, Construction Models, Instrument Panels, Wooden Products, Etc. With the Assist of the Cnc Router 3040t, Your Design Idea Will Be Real-time Display. The New 0.8kw Water- Cooled Vfd Is Available Operating for Long Time, Which Can Reinforced the Processing. Abilty of the Machine and Can Be Used to Process Aluminum Alloy and Hard Wood. Anti- Blackflash, High Precision, Long Life Circle. Connecting the Control Box with the Cnc Machine and You Computer and Make Sure the Plug Will. Don’t Suspended the Cable Which Connect the. Spindle Motor with Axis(X, Y, Z, a). Model Six:usb 4 Axis Cnc 3040 Router 400w. 4 Axis 3040 400w. More Precise Stepping Motor. The Engraving Process Is Visible As Controlled by Computer. Simple Operation and Installation. Cnc 3040 Is Suitble for Industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. Cnc3040 Is a Desktop Cnc Machine and Designd for Processing Industrial or Hobby Prototype Building, Building Model Making, Pcb. Adverstising Signs, Artwork, Crafts, Aircraft Models, Rc Model Parts, Etc. So, You Can Do Engraving Work at Office or Home. Exquisite 3040 Is a Miniature Version of Mobile Longmen Structure of Carving Machine, Put on You Computer Is like Puting a Printer or Scanner That Coordination, and Can Completely As a Compute Peripherals Tools, Anywhere, Anytime, Help You to Design Intent Fast Real Appear. Nonmetal Materials on the Milling, and It Can Also Be Used to Carving Simple Pcb/Cnc. This 3040 Engraer Is a User-friendly Desktop Engraving Machine for Those with Limited Space and /or a Limited Budget. The Computerized Cnc Engraving and Cutting Machine Is Suitable for Various Materials, Such As Wood, Pmma or Other Plastic. Mdf Board, Native Wood, Pvc, Acrylic, Wood, Composite Board Plywood, It Can Be Used Widely to Process or Make Adverstising Signs, Pcb. Nameplates, Badges, Seals, Bronzing Plate, Aluminium Alloy, Acryplates, Abs Resin Double Color Plate, Pvc Foaming Board, Indentation Plates, Signs. Construction Models, Instrument Panels, Wooden Products, Etc. Effective Working Travel:275(X)Mm385(Y)Mm60(Z)Mm. Work Table Dimension:320mm530mm. Frame Materials:aluminum Alloy 6063 and 6061. Leadscrew:1404 Double Thread Trapezoidal Screws. Driving Units:x Axis:1204 Trapezoidal Screws. Y Axis:1204 Trapezoidal Screws. Z Axis:1204 Trapezoidal Screws. Sliding Units:x Axis:dia. 16mm Chrome Plate Shafts. 12mm Chrome Plate Shafts. Stepping Motor Type:57 Two-phase 1.8a. Spindle Motor:400w Dc Motor 5008000prm/Min. Principal Axis Collet:er11 / 3.175 Mm. Spindle Precision:radial Beat Acuities 0.03 Mm. Control Unit:triaxial One-piece Drive + Ring Variable Power + Pwm Speed. Communication Interface:usb Port. Support System:windows Xp / Win7, 32bits. Control Unit:2.5a Stepping Motor Driver plus Adjustable Spindle Speed Controller. Computer Connection:usb Port. Make Sure That Your Computer Has a On-board Usb Port Output. Connecting the Control Box with the Cnc Machine and You Computer. Model Seven:usb 4 Axis Cnc 3020 Router 300w. 3020t 4axis Cnc Router Engraver Drill Milling Machine 3d Cutter Artwork. Item Units and Pictures (What You See What You Get). Cnc 3020 Is Suitble for Industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. Cnc 3020 Is a Desktop Cnc Machine and Designd for Processing Industrial or Hobby Prototype Building, Building Model Making, Pcb, Adverstising Signs, Artwork, Crafts, Aircraft Models, Rc Model Parts, Etc. So, You Can Do Engraving Work at Office or Home. Exquisite 3020 Is a Miniature Version of Mobile Longmen Structure of Carving Machine, Put on You Computer Is like Puting a Printer or Scanner That Coordination, and Can Completely As a Compute Peripherals Tools, Anywhere, Anytime, Help You to Design Intent Fast Real Appear. Engrave Almost Anything on Almost Any Surface. X? Y? Z Axis Carving Make More Precise and and Three-dimensional Effect. Cover Plates Reducing Pollution for the Screws and Shafts. More Steady and Strong Equiped with Aluminum Alloy Frame Materials. Reinforced and Thickened Machine Body Make Transportation Absolutely to Be Safer and Longerlife Time. This 3020 Engraer Is a User-friendly Desktop Engraving Machine for Those with Limited Space and /or a Limited Budget. The Computerized Cnc Engraving and Cutting Machine Is Suitable for Various Materials, Such As Wood, Pmma or Other Plastic, Mdf Board, Native Wood, Pvc, Acrylic, Wood, Composite Board Plywood, It Can Be Used Widely to Process or Make Adverstising Signs, Pcb, Nameplates, Badges, Seals, Bronzing Plate, Aluminium Alloy, Acryplates, Abs Resin Double Color Plate, Pvc Foaming Board, Indentation Plates, Signs, Construction Models, Instrument Panels, Wooden Products, Etc. 3020t Triaxial Engraving Machine Part Parameters. Effective Working Travel : 200(X)Mm300(Y)Mm45(Z)Mm. Frame Materials : Aluminum Alloy 6063 and 6061. X Axis 1204 Trapezoidal Screws. Y Axis 1204 Trapezoidal Screws. Z Axis 1204 Trapezoidal Screws. 13mm Chrome Plate Shafts. Stepping Motor Type : 57 Two-phase 1.45a-2a. Spindle Motor: 300w Dc Motor. Principal Axis Collet: Er11/3.175 Mm. Spindle Speed : 300 8000rpm/Min (Pwm Stepless Speed Regulation). Empty Line Speed: 0-2500mm/Min (16 Subdivided Driving down). Spindle Precision: Radial Beat Acuities 0.03 Mm. Control Unit: Triaxial One-piece Drive + Ring Variable Power + Pwm Speed. Carving Instructions: G Code/Tab Files/Nc File/Ncc Files. Communication Interface Through Usb Port with Computer. Support System : Windows 7/ Xp. Carving Speed: 0-2000mm/Min (Different Materials Differ). Control Unit :2.5a Stepping Motor Driver plus Adjustable Spindle Speed Controller. Command Code G Code. Protection Emergency :Stop Button. Can Be Controlled by Computer. Can Control the Engraving More Precise. Emergency Stop Button Enhance Security. Large 3d Engraving in Soft Wood, Mdf Board, Native Wood, Pvc, Acrylic We Suggest Use One or Two Spiral Flute Ball Bits. Can Engraving Much More Materails by Spiral Flute Bits, Such As Metal, Steel, Mdf Board, Solid Wood, Composite Board Plywood, Stone. Spindle Motor Knob Is Useful for Small Positioning Adjustment, with Steady and Strong Support Structure. The Reinforced and Thickened Machine Body Make Transportation Absolutely to Be Safer and Longer Life Time. The Chrome Shafts Is Not Easy to Deform, Suitable for Long Time Use. Flexible Coupling Can Be Used for High Torque Transmission. High Precision Stepping Motor Makes Engraving More Precise. 32-Bit Version of Windows 2000, Windows Xp, Windows Vista, or Windows 7 (64-Bit Versions Will Not Work) 1ghz Cpu 512mb Ram Non-integrated Video Card with 32mb Ram(Large G-code Files, Especially 3d Files Will Require a Video Card with 512mb Ram or Higher). Model Eight:usb 3 Axis Cnc 3040 Router 400w. Usb Cnc Router 3 Axis 3040 400w Engraver/Engraving Milling M/C 110av More Precise Stepping Motor The Engraving Process Is Visible As Controlled by Computer Simple Operation and Installation Engrave Almost Anything on Almost Any Surface X? Y? Z Axis Carving Make More Precise and and Three-dimensional Effect Cover Plates Reducing Pollution for the Screws and Shafts. More Steady and Strong Equiped with Aluminum Alloy Frame Materials Reinforced and Thickened Machine Body Make Transportation Absolutely to Be Safer and Longer Life Time. Introduction Cnc3040 Is Suitble for Industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes. Cnc3040 Is a Desktop Cnc Machine and Designd for Processing Industrial or Hobby Prototype Building, Building Model Making, Pcb, Adverstising Signs, Artwork, Crafts, Aircraft Models, Rc Model Parts, Etc. So, You Can Do Engraving Work at Office or Home. This 3040 Engraer Is a User-friendly Desktop Engraving Machine for Those with Limited Space And /or a Limited Budget. 3040t Triaxial Engraving Machine Part Parameters: Effective Working Travel :275(X)Mm385(Y)Mm70(Z)Mm Shape Dimension :610x480400mm Max. Workpiece Dimension :60mm Work Table Dimension :320mm530mm Frame Materials :Aluminum Alloy 6063 and 6061 Leadscrew :1404 Double Thread Trapezoidal Screws Driving Units X Axis:1404 Trapezoidal Screws Y Axis:1404 Trapezoidal Screws Z Axis:1404 Trapezoidal Screws Sliding Units X Axis:dia. 16mm Chrome Plate Shafts Y Axis:dia. 16mm Chrome Plate Shafts Z Axis:dia. 12mm Chrome Plate Shafts Stepping Motor Type :57 Two-phase 1.8a Spindle Motor :400w Dc Motor 5008000prm/Min Principal Axis Collet :Er11 / 3.175 Mm Repeat Accuracy :0.05mm Spindle Precision :Radial Beat Acuities 0.03 Mm Control Unit :Triaxial One-piece Drive + Ring Variable Power + Pwm Speed Carving Instructions :G-code/. Txt Communication Interface :Through Usb Port with Computer Support System :Windows Xp / Win7 Maximum Idle Speed:1500mm/Min Working Speed :50-1500mm / Min (Different Material with Different Speed Settings) Machine Weight :28kg. Operating Voltage: Ac110v Us Plug Control Unit: 2.5a Stepping Motor Driver plus Adjustable Spindle Speed Controller Computer Connection: on Board Palrallel Port Command Code: G Code Protection: Emergency Stop Button. 1× Engraving Machine 1× Control Box 1× Usb Cable 1× Power Cable.

Comments Off