2019

High Speed Milling Small Aluminum Accessories

Comments Off

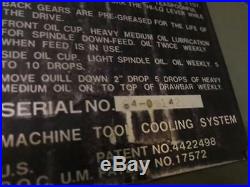

DOALL VARIABLE SPEED MILL W/ POWER FEED – 54″ X 9″ TABLE. This is a fixed listing for a DoALL Milling Machine. Specifications: Make: DoALL Type: Vertical Mill Table Size: 54″ x 9″ Power Feed Installed Variable Speed: 60-4200 RPM. The mill is exactly as pictured and has been tested to be in operational condition. We will load your truck or carrier free of charge at our loading dock. International buyers are always welcomed. Get Images that Make Supersized Seem Small. Tailor your auctions with Auctiva’s. Track Page Views With. Auctiva’s FREE Counter. The item “DOALL VARIABLE SPEED MILL With POWER FEED 54 X 9 TABLE” is in sale since Monday, October 30, 2017. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “dockguys” and is located in Rochester, New York. This item can be shipped worldwide.

Comments Off

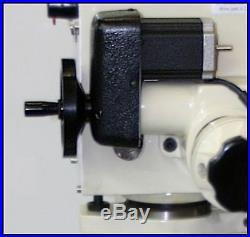

The CNC Express SQ Model has ample 20″ x 9″ travels to accommodate your larger parts! Now with even more powerful motors! The CNC Express SQ is well proven, offers a good size working envelope, runs on 115 or 230 VAC single phase power, has high speed machining, and accommodates coolant, and spindle control. The custom made anti-backlash ballscrews allow precision conventional and climb milling operations as well as accurate circular and contour cuts along any pair of axes without time consuming setups. Offering impressive machining power, repeatability, in a relatively small footprint. The square column CNC Express Milling Machines are available in two sizes, the CNC Express SQ medium size and the extra large CNC Express XL Gearhead models! Compare the specifications and choose the one that is right for you. The Stand, tray and basic accessories are included with the system at no extra charge. Our own custom designed software is complete with built-in graphic test mode and geometry wizards! Other systems use generic 3rd party software and they have no control on features or updates. Precise, powerful, and over 150 in/min rapids! Supports the latest operating systems and includes our advanced USB motion controller! Includes the stand, chip tray, accessories, and professional crating (Domestic orders) all at no extra charge. MN400 Motion Controller (Included in DriveRack). MillMaster Pro for Windows. The latest technology constant current chopping drives used in the. Power electronics result in very high feed and rapid rates, while our fully optoisolated. Motion controller insures maximum reliability with the use of opto-isolated inputs and outputs on. Other systems may use direct connection or a printer port whose reliability is typically not suitable for industrial applications. Since our CNC machines are designed around existing manual machines, they accept standard tools and accessories. This means you won’t have to spend a fortune on specialized or custom tooling. The most commonly needed ones are included with the package for convenience and added savings. We also offer a full assortment of practical tools and accessories to choose from below in the optional accessories section. MicroKinetics CNC systems are expertly built and performance tested to conform to stringent standards. Detailed assembly and testing procedures and checklists are followed to insure consistent, repeatable, high quality machines. CNC Express (Also available). CNC Express SQ (This listing). CNC Express XL (also available). 17.00 (432 mm). 20.00 (508 mm). 28.00 (711 mm). 7.00 (178 mm). 9.00 (229 mm). 12.00(305 mm). 5.00 (127 mm). 4.75 (121 mm). Swivel 360 Degrees 15 7/8 (403 mm). Tilt 90 Degrees Left 90 Degrees Right. 8 1/4″ × 28 1/2″ (210 mm X 724 mm). 9 1/2″ × 32 1/2″ (241.3 mm X 825.5 mm). 9 3/8″ × 39 1/2″ (238 mm X 1003 mm). New Variable Speed 100 to 3000 RPM with included VFD. Torque selectable via gearing. New Variable Speed 100 to 3200 RPM with included VFD. 230VAC 1 PH 10 Amp. 115VAC (230 optional) 1 PH 15 Amp. Floor Space & Height. 42″ Deep ×58″ Wide x 62 Height (1.07 m x 1.47 m x 1.57 m). 46″ Deep ×66″ Wide x 68 Height (1.17 m x 1.68 m x 1.73 m). 50″ Deep × 80″ Wide x 75 Height (1.27 m x 2.03 m x 1.91 m). CNC Express Unique Advantages. More torque where it counts – Our NEW, custom made 750 oz-in motors deliver 41% more torque in bipolar drive method used here plus a 2 to 1 pulley ratio produces over 1500 oz-in of torque at the drive shaft. This maximizes the torque available at the full range of speeds, not just the holding torque. The overall performance with a properly engineered system of mechanics and electronics results in very impressive forces at standstill, at typical cutting speeds and at rapid positioning speeds. Limit switches included in both directions on X and Y and up direction on Z for more convenient referencing and for end of travel without relying solely on mechanical dead stops. Mechanical dead stops provide excellent redundancy which comes into play in the event a limit sensor is not recognized for any reason. While the electronic limit sensors almost never fail, it is great to have this design for setup and testing. Lifetime timing belts that are overdesigned. To never break or need replacement in this application but are important in achieving low vibration and smooth operation. High voltage drivers offer impressive high speed performance (over 150 Inches per minute typical). No thrust bearings – We use high performance tapered roller bearings. Many other competing models use thrust bearings which limit the speed and features or updates. We listen to our customers and add features regularly. Now MillMaster pro offers more G-codes and M-codes than ever, plus Windows 10/8/7/Vista/XP support. Controls and graphically simulates a 3-axis milling type CNC control on any PC running Windows 98/2000/XP/Vista/7/8. The CNC part program can be typed directly into the editor screen, or can be generated via a CAD/CAM program. The interactive mode allows you to see the operation performed graphically as you type each CNC line, aiding in part program development or training. For documentation purposes, you can print the graphics screen and the part program together or separately. True circular interpolation on any two axes and simultaneous linear interpolation on all axes are standard. This allows full 3-D surfacing designs to be run on the target 3 axis machine. Bed mill base system with 2 HP single phase or 3 phase motor. 003 per foot max linear error. Stepper motors (2) 34M750 (1) 23HT350. High performance power Multidriver. Continuous contouring motion controller. G-code control & graphical software. Limit switches, cables, and technical manuals. Included accessories: Cabinet stand with chip pan, shelf and latched door plus the following pictured accessories. 52 Piece Clamping Set. Drill Chuck with Key. 4 Precision CNC Vise. Face Mill with 4 HSS inserts. Covering the front and both sides of the table, this shield provides an added safety measure and retains chips and fluid, keeping the work area clean. The front forward slant design offers improved functionality. No drilling or tapping is needed – the guard mounts easily with two thumbscrews (provided). 6″ and 8″ Vertical/Horizontal. Increases tool life, lubricates metal cutting process and reduces heat buildup. Use with water soluble concentrates and light cutting oils. It comes complete with a tank , pump, 6′ plastic hose, flexible nozzle with valve, and a screen strainer. The pump comes with a 6′ 3-conductor cord with a three- prong plug 110VAC. 110V to 220V transformer available. High Speed Steel 3/8 shank Includes six 2-flute end mills: 1/8, 3/16, 1/4, 5/16, 3/8, 1/2 Comes with wooden organizer stand. 3 Jaw Chuck & Adapter for Rotary tables. 4 Jaw Chuck & Adapter for Rotary tables. High Speed Steel 3/8 shank Includes six 4-flute end mills: 1/8, 3/16, 1/4, 5/16, 3/8, 1/2 Comes with wooden organizer stand. Titanium Coated for longer life High Speed Steel &bull Center Cutting, Single End Complete with wooden storage case 10 pieces 2-flute: 3/16 – 3/4 by 16ths 10 pieces 4-flute: 3/16 – 3/4 by 16ths. Made of high grade steel and precision ground to close tolerance. Sizes: 1/8 to 3/4 by 8ths. R8 Quick Change Tooling. Engineering Quality CNC Components and Systems Since 1985. The free listing tool. The item “New Geared Head Variable Speed spindle Square Column CNC Milling Machine” is in sale since Saturday, July 23, 2016. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “microkineticscnc” and is located in Kennesaw, Georgia. This item can be shipped worldwide.

Comments Off

THIS LISTING COMES WITH A STAND. IF YOU WOULD LIKE A MACHINE WITHOUT THE STAND, PLEASE SEE OUR OTHER LISTING. Variable Speed Head, with all Hardened and Ground Steel Gears for. This machine uses 120V Standard Power! Highlights Of This Machine. Variable Spindle Speeds to perfectly match the speed to the job. Wide speed range, 40-3000 RPM. All Hardened and Ground Steel Gears in head, for much heavier. Cutting capability, particularly when compared with plastic gear equipped models. Compact Size for smaller work shops, but has more weight and power to. Remove material when needed. 001 on X and Y with a true Inch Pitch. Leadscrew, leads to easier operation when tolerances matter. Main Column is attached to the base with 4 bolts from the top, with. A very wide mounting surface for much more rigidity over other. Models in this size range. Only Requires Standard 120V Single Phase Circuit, so it can be. Set up virtually anywhere, without needing additional circuits. Installed in your work shop. Compact, Accurate, Economical Machine. Great for those who are looking for a compact machine for a smaller work shop, yet need the ability to take heavier cuts compared with other machines in this size range Spindle is Supported by High Precision Tapered Roller Bearings Mill Head May be Tilted ±90° (both left and right) Precision Manual Fine Down Feed is standard Adjustable Tapered Gibs for longer life Positive Locks are standard for Table, Head, Quill, and Column Easy Reading Dials Have Satin Chrome Finish, Graduated in. 001 Quill DRO is Standard, Accuracy of the Display 0.0005, Selectable from mm/inch Generous 18-1/4 Spindle To Table Max Distance for taller work 8-1/2 Y Axis Travel, More than other machines in this class. Average time delivered is 2-7 days depending on how far from Pittsburgh you are, it could be a little longer in remote places but normally is very fast. 1060 Montour West Industrial Park. We are machinists here too, so we know what we sell. This is really a top quality machine, and will last a long, long time. AND we are here for support too. We sell these machines regularly, we know them inside and out, and have been in business for many years, so if there is any question, we can help. End Milling Capacity: 1. Face Milling Capacity: 3. Table Size: 27-1/2 x 7-1/8. Cross Travel (Y Axis): 8-1/2. Longitudinal Travel (X Axis): 15. Table Leadscrew Pitch 10 TPI. Vertical Travel (Z Axis): 16. Max Distance Spindle to Table: 18-1/4. Taper of Spindle: R-8, w/7/16-20 Drawbar Thread. Spindle (Quill) Travel: 3. T Slot Size: 1/2T Slots are slightly less than 1/2, actual size 12mm, our 1/2 kit. Is sized for this machine. Range of Spindle Speeds: 40-3000 RPM, 6 STEPS and Variable. Head Tilt: Left & Right ±90°. Net Weight: 575 LBS. Power Required: 110/120V, 20 Amp Circuit. Dimensions: 39W x 70H x 30D. NO extra charge for residential or anything on these, as long as a truck can get to you, its covered. If you have ANY questions, feel free to message us. Check out our other auctions for more lathes and mills. The item “PM-727V VERTICAL BENCH TOP MILLING MACHINE WithSTAND VARIABLE SPEED FREE SHIPPING” is in sale since Wednesday, May 22, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “qualitymachinetools” and is located in Pittsburgh, Pennsylvania. This item can be shipped to United States, Canada.

Comments Off

Power Feed APF-500X Torque for Type Milling Machines 0-210 RPM Feeding Device. The machine is used for X axis, if you want to used for Y axis, a SUPPORT PLATE will be needed. You are looking at our new Power Feed X for Bridgeport and Similar Knee Type Milling Machines. These will fit almost any vertical knee type mill out there with the 5/8 Shaft End, Including but not limited to Bridgeport, Precision Matthews, Grizzly, Enco, Jet, Sharp, Acer, Webb, GMC, Kent, Clark, Supermax, Enco, Turn Pro, Vectrax, Acra, Birmingham, Accu, First… The gear ratio between transmission plastic gear and motor shaft gear is not a whole number. 107T for plastic transmission gear and 6T for motor shaft gear 107 is not divisible by 6, 107 % 6 = 17.8333333333… The two gears will not mesh and wear at the same spot, this not only increases durability and longevity but even reduces noise over time. Set the fix stand on work table, set table bearing bushing on the axis screw, then set the power table feed on the fix stand, take out the gear housing. Use one hand to hold the center transmission shaft. Set the bevel gear on axis screw with the other hand. Then check if the backlash between gears is between 0.1-0.2mm. Add shims (1.0t, 0.25t, 0.1t) if the backlash is too large. Repeat step 2-3 until reaching satisfying backlash. Tighten the handle to start setting socket parallel key and bevel gear. Rotate the handle slightly to feel if any interfere occurs in between. If do, please repeat step 3-4 to add more shims. If not, go to next step. Take out the handle, add proper shim (43×33), adjust the backlash between dial & bevel gear and lock with fix ring. Set the handle and tighten, slightly rotate the handle. Normally it should be smooth without any interfere. Finally, set the gear housing and limit switch. Power supply switch and reset switch. The right side of power switch is ON. The left side is OFF. Red light will show when machine is on. The red round button on right side is reset switch. Reset button will jump up to cut off the power if the machine overloads. The operator must reduce cutting load, then press reset switch to continue operating. Feed knob and rapid button. Rotate feed knob after power is on. Turn left for left side feeding and vice versa. The button in the middle is rapid button. Tool will travel rapidly to left side if you keep pressing the button. Release to make power table feed will back to normal speed. Speed can be adjust according to operators requirement, ranging from 0-9. Normally, jog switch should be at FEED position. For jog movement, just switch to “0″ position. Kept holding the switch until it travels to requires position. NOTE: To stop jog operating, you must first turn FEED KNOB TO 0(OFF) position. Then move JOG SWITCH to FEED position. Be sure to follow the procedure for jog operation to avoid any damage caused by wrong movement. Gear cover must be open every 6 month to check whether lubrication for spiral gear is sufficient. Graphite type lubrication is suggested rather than silicon type. Carbon brush cap should be open every 6 month to check if the brush has wore out. Brush should be replace immediately if its length is under 5mm (front and back brush should be replaced together). Add an auto power table feed to your milling machine. A simple and inexpensive way to increase productivity. Small volume and easy installation. Excellent speed control in the entire range. Jog function operates at any feed speed. Power table feed won’t vibrate or strain in low speed. Direction control knob for easy and rapid operation. Safety feature to protect transmission gear and electronic components. Package Dimensions: 11713(275175335mm). 1 x X-Axis Fix Stand with Bushing. 1 x Bevel Gear with Fix Ring. 1 x Handle Washer. 2 x Stop Blocks. 2 x Stop Set. 2 x Socket Screws (M8P1.2535). X Socket Screws M8P1.0. 6 x Small Shims. 2 x Small Shims 26.2. 3 x Small Shims 26.2. 4 x Large Shims. 2 x Spring Pins. 1 x Cable Clamp. 1 x User Manual. Sign up to newsletter. As a leading and emerging company in manufactory and exporting business, we are specialized in Business and Industrial Products, Sporting Goods, Pet Products, Home and Garden products for more than 10 years. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. If you have any changes, pls inform us. These charges are the buyers responsibility. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Leave a Message if. You want to cancel an order. If you need further assembly instructions for a product. Any other unspecified questions or concerns. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. A: The item ships from Rancho Cucamonga, CA, United States. A: Please log on your account. Q: How do I return an item? Please contact our customer service before you return an item. The item “X AXIS POWER FEED MILLING BRIDGEPORT ACER ADJUSTABLE SPEED MILLING MACHINE” is in sale since Monday, November 13, 2017. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “bilibusyeasy_4″ and is located in Ontario, California. This item can be shipped to United States, Canada, Mexico, Germany.

Comments Off

General Info: Stock #: CL-B-191016 Location: Cumming, GA 30041 Brand: Bridgeport Model: Series 1 Serial #: 142488 Approx. Also has a shaper affixed to the back. Additional Info: Machine is under power and can be demoed upon request. We always recommend machine be inspected in person to verify condition. If you have any specific questions or would like to set up a time to view this piece of machinery feel free to contact the contact person for this listing 7 days a week. Purchaser shall pay The Equipment Hub a late penalty on all amounts over 30 days past due computed on an interest rate equal to 18% per annum. The Equipment Hub SHALL NOT BE RESPONSIBLE FOR THE CONSEQUENCES OF PURCHASER’S FAILURE TO INSPECT THE EQUIPMENT OR MERCHANDISE OR FOR ANY INACCURACIES, INSUFFICIENCIES, OR OMISSIONS IN SUCH DESCRIPTIONS, SAMPLES, TOLERANCES AND/OR SPECIFICATIONS. The employees or representatives of The Equipment Hub are not authorized to make any statement or representation as to the quality, character, size, condition, quantity, etc. Of the equipment and merchandise offered for sale inconsistent with these Terms and Conditions. Any such statements made will not be binding on The Equipment Hub or be grounds for any subsequent claim. All implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed and excluded from this agreement. Care is taken to give reliable descriptions but these are not guaranteed and prospective purchasers are advised to check vital details. We also reserve the right to correct any stenographic errors. All specifications and descriptions of said goods are approximate only. THE WARRANTIES DISCLAIMED HEREUNDER INCLUDE, BUT ARE NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No salesman or other representative of The Equipment Hub has authority to make any warranties. It is Purchaser’s responsibility to inspect the goods and to ascertain if the specifications, tolerances, descriptions and condition of the goods conform to the Purchaser’s requirements. Purchaser does hereby discharge The Equipment Hub from any and all liability directly or indirectly resulting from the presence of the aforesaid chemicals or materials, including and not limited to any and all liability directly or indirectly resulting from the failure of The Equipment Hub to give more specific warning with respect to individual articles or substances or from the inadequacy of any warning. Suggestions by The Equipment Hub regarding the design, specification, tolerances, use or suitability of the Products are made in good faith but are not binding upon any party and do not give rise to any liability by The Equipment Hub. MODIFICATIONS/ SEVERABILITY: Purchaser acknowledges that these are the only Terms and Conditions of sale, and is intended by the parties as a complete and exclusive statement of the terms of their agreement. This supersedes all prior agreements, written or oral. Any variation from the terms hereof contained in the Purchaser’s acceptance is hereby rejected. The agreement of which these terms are a part can be modified or rescinded only in writing signed by The Equipment Hub. If any provision of the invoice or these Terms and Conditions is determined illegal or unenforceable, it shall not affect the enforceability of any other provision or paragraph of the invoice or these Terms and Conditions. The remedy hereby provided shall be the exclusive and sole remedy of Purchaser and any right to consequential and incidental damages is excluded. The item “Bridgeport Series 1 Variable Speed Vertical Milling Machine” is in sale since Thursday, March 28, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “equipmenthub” and is located in Cumming, Georgia. This item can be shipped to United States.

Comments Off

General Info: Stock #: CD-191052 Location: Stone Mountain, GA Brand: Bridgeport Model: Series 1 Serial #: 124205 Approx. Check out the video on the listing to see it in operation. We are glad to show under power. Video will open in a new window. If you have any specific questions or would like to set up a time to view this piece of machinery feel free to contact the contact person for this listing 7 days a week. Purchaser shall pay The Equipment Hub a late penalty on all amounts over 30 days past due computed on an interest rate equal to 18% per annum. The Equipment Hub SHALL NOT BE RESPONSIBLE FOR THE CONSEQUENCES OF PURCHASER’S FAILURE TO INSPECT THE EQUIPMENT OR MERCHANDISE OR FOR ANY INACCURACIES, INSUFFICIENCIES, OR OMISSIONS IN SUCH DESCRIPTIONS, SAMPLES, TOLERANCES AND/OR SPECIFICATIONS. The employees or representatives of The Equipment Hub are not authorized to make any statement or representation as to the quality, character, size, condition, quantity, etc. Of the equipment and merchandise offered for sale inconsistent with these Terms and Conditions. Any such statements made will not be binding on The Equipment Hub or be grounds for any subsequent claim. All implied warranties of merchantability and fitness for a particular purpose are hereby disclaimed and excluded from this agreement. Care is taken to give reliable descriptions but these are not guaranteed and prospective purchasers are advised to check vital details. We also reserve the right to correct any stenographic errors. All specifications and descriptions of said goods are approximate only. THE WARRANTIES DISCLAIMED HEREUNDER INCLUDE, BUT ARE NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No salesman or other representative of The Equipment Hub has authority to make any warranties. It is Purchaser’s responsibility to inspect the goods and to ascertain if the specifications, tolerances, descriptions and condition of the goods conform to the Purchaser’s requirements. Purchaser does hereby discharge The Equipment Hub from any and all liability directly or indirectly resulting from the presence of the aforesaid chemicals or materials, including and not limited to any and all liability directly or indirectly resulting from the failure of The Equipment Hub to give more specific warning with respect to individual articles or substances or from the inadequacy of any warning. Suggestions by The Equipment Hub regarding the design, specification, tolerances, use or suitability of the Products are made in good faith but are not binding upon any party and do not give rise to any liability by The Equipment Hub. MODIFICATIONS/ SEVERABILITY: Purchaser acknowledges that these are the only Terms and Conditions of sale, and is intended by the parties as a complete and exclusive statement of the terms of their agreement. This supersedes all prior agreements, written or oral. Any variation from the terms hereof contained in the Purchaser’s acceptance is hereby rejected. The agreement of which these terms are a part can be modified or rescinded only in writing signed by The Equipment Hub. If any provision of the invoice or these Terms and Conditions is determined illegal or unenforceable, it shall not affect the enforceability of any other provision or paragraph of the invoice or these Terms and Conditions. The remedy hereby provided shall be the exclusive and sole remedy of Purchaser and any right to consequential and incidental damages is excluded. The item “Bridgeport Series 1 9 x 42 Variable Speed Vertical Milling Machine, Newall DRO” is in sale since Friday, May 3, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “equipmenthub” and is located in Stone Mountain, Georgia. This item can be shipped to United States.

Comments Off

BRIDGEPORT STYLE MILLING MACHINE VARIABLE SPEED HEAD SHARP BRIDGEPORT MILL. It does operate correctly, but does need a upper bearing replaced near the brake drum. The item “BRIDGEPORT STYLE MILLING MACHINE VARIABLE SPEED HEAD SHARP BRIDGEPORT MILL” is in sale since Monday, May 6, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “1070lemans” and is located in Elizabethtown, Indiana. This item can’t be shipped, the buyer must pick up the item.

Comments Off

NO STAND WITH THIS LISTING. IF YOU ARE LOOKING FOR A STAND, PLEASE SEE OUR OTHER LISTING. Extremely Reliable, Brushless DC Variable Speed Motor Included Standard. Belt Drive Design, For Smoother, Quieter Running. Extra Large Column To Base Mount. 3 Bolt Head to Column Mount is Standard, Also For Increased Rigidity. Larger Dials at Table Ends, Graduated in. 001, For Easier Reading, And More Accurate Table Movements. Leadscrews Are True Inch Pitch Screws (Not Metric Conversions Like Many), 10 Threads Per Inch. More Information below It is NOT just the same old model with just a belt drive upgrade Be sure to compare carefully. Special Features that set this mill apart from others (BE SURE TO COMPARE THESE DIFFERENCES). MUCH Larger Travels and work area. Quill DRO Included Standard (This is for the spindle up/down movement). 3 Bolt Head Mount is now standard (where the head mounts to the Z Axis), for more rigidity when milling Much improved over the single bolt mount type. Main Z Axis Column is attached to the base with 4 bolts, and mounted from the top, with a wide, proper mounting surface for much more rigidity over other models in this size range. 001 Readings with larger dials on the X and Y axis, with true 10 Thread Per Inch Leadscrews make it easier to cut accurately One line on the dial is. 001, one full turn of the handwheel is. 100, much easier to use than those with odd metric conversions. 50-3000 RPM variable speed with the turn of a knob, properly set up with Low and High for a wider speed range, and plenty of power at lower speeds. Precision ground ways for smoother movements Not just rough milled. Thrust Bearings in leadscrew ends not bushings Much smoother movements and less backlash. Split nuts on X and Y Axis to allow for backlash adjustment. DC BRUSHLESS MOTOR, Variable Speed, POWERFUL, SMOOTH, and RELIABLE Belt Drive from Motor to Spindle runs MUCH quieter than others, and eliminates any failure prone plastic gears (And the hassle of changing them when stripped). Variable Speed with Belt Drive and Brushless DC Motor 4. Way Cover Set 5. R8 Spindle Taper 7. Quill/Spindle Depth DRO 8. PM30MV (DC Brushless Motor, and Belt Drive Head is Standard) Max. Drilling Capacity 1-1/4 Max. End Milling Capacity 3/4 Max. Face Milling Capacity 3-1/2 Table Size 8-1/4 x 33 Cross Travel (Y Axis) 8-3/4 Longitudinal Travel (X Axis) 23 Table Leadscrew Pitch 10 TPI. 100 Per Turn Table Dial Graduations. 001 Vertical Travel (Z Axis) 14 Max Distance Spindle to Table 17 Taper of Spindle R-8, w/7/16-20 Drawbar Thread Spindle Travel 3 T Slot Size Actual size 14mm, our 9/16 kit listed is sized for this machine Range of Spindle Speeds 50-3000 rpm, 2 Ranges (Properly set up with high and low range belt positions for more power at lower speeds as it should be) Headstock Tilt Left & Right ±90° Motor 2 HP Net Weight 530 LBS Power Required 220V, Single Phase, 10 Amp. Dimensions Height, Head at normal working height (W/O Stand) 39 Max Height, Head at top of travel (W/O stand) 48 Width, Tip to Tip of table handles 46-1/4 Dimension Front To Back, from back of chip pan, to front table handle tip 31 (Can be pushed back against a wall, and table handle tip will be 31 from wall). Average time delivered is 2-7 days depending on how far from Pittsburgh you are, it could be a little longer in remote places but normally is very fast. 1060 Montour West Industrial Park. If you have ANY questions, feel free to message us. Check out our other auctions for more lathes and mills. The item “PM-30MV VERTICAL BENCH TYPE MILLING MACHINE VARIABLE SPEED FREE SHIPPING” is in sale since Wednesday, April 17, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “qualitymachinetools” and is located in Pittsburgh, Pennsylvania. This item can be shipped to United States, Canada.

Comments Off