2024

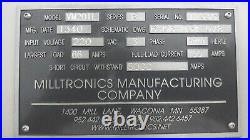

Milltronincs Model VM20 CNC Vertical Machining Center, S/N 9899

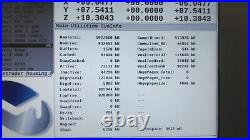

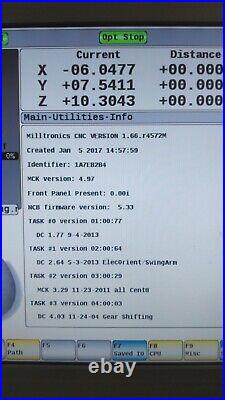

Table Size – 44″ x 20″ Table Travels (XYZ) – 40″ x 20″ x 26″ Throat Distance – 21″ Distance, Spindle to Table Top – 4″ to 30″ Maximum Table Load – 2000 Lbs. 1 min / 30 min. 24/15 HP Spindle Speeds – 8,000 RPM Spindle Taper – CT40 Carousel Type Tool Changer # of Pockets – 24 Rapid Traverse – 1000 IPM Max Feedrate (Part Dependent) – 500 IPM Floor Space Requirement – 112″ x 92″ Machine Weight, Approx – 10,000 Lbs. Milltronics Centurian 7 CNC Control 10 LCD Color Display Conversational plus G & M Code Programming 3D Part and Tool Path Graphics Front Panel Electronic Handwheel with Handwheel Feed Auxiliary Keyboard Port for PC Keyboard with Optional Tray Electronic Spindle Orient AC Brushless Digital Servo Drives Flood Coolant Spray Mist Auto Lubrication Full Enclosure Software Package A Convenience Package B Performance Package C Specs Subject to Verification.

Comments Off