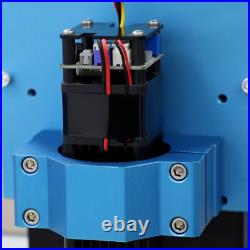

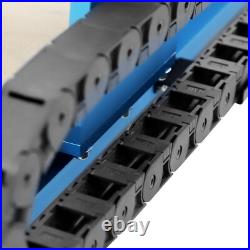

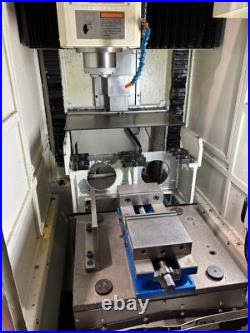

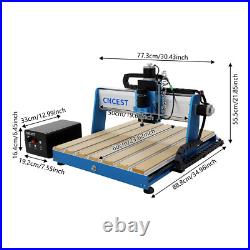

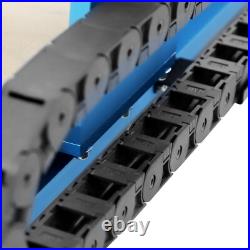

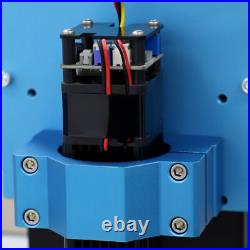

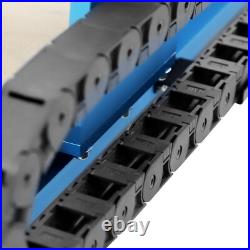

3 Axis CNC 6050 Milling Carving Engraver Router Machine Engraving Machine 500W. Welcome to our store. Our sophisticated engraving machine stands as a pinnacle of craftsmanship, poised to serve as an invaluable aide in your artistic endeavor of carving. With its precision-engineered design, it transforms mere materials into intricate masterpieces, elevating your woodworking craftsmanship to new heights. This elegantly crafted tool doesn’t merely shape wood-it breathes life into your vision, harmoniously fusing artistry with technology. Build to Last: It is composed of high-quality aluminum alloy with a sandblasting anodizing process, which makes it rust-resistant, sturdy, and has a long service life. Powerful Function: It uses a 57-76 stepper motor with a power of 500W and a speed of 10000rpm, which can efficiently and accurately carve according to your carving needs. Thoughtful Design: It adopts XYZ three-axis and easy-to-use integrated control box, with speed regulation, E-Stop, and Reset functions, which can better present your carving skills. In addition, it supports the Windows XP/7/8/10 system, making it easy for you to connect to a computer for precise engraving. Safety Protection: It has an air cooling design and an emergency stop switch, which can ensure timely heat dissipation, as well as the stability and use safety of the product during operation. Enjoy DIY: With it, you can do your own woodworking or plastic DIY to create your favorite works and enjoy the creative process! Ideal Gift: Because of its practicality and powerful functionality, you can give it as a Christmas, Thanksgiving, or Halloween gift to your worker friends. Protective Package: We have used sponge wrapping to minimize damage to the product during transportation. It is our pleasure to answer your confusion and questions. Sturdy Collet: You can mount the drill bit(not included) securely for engraving. Chain Design : The drag-chain cable design is not easily tangled and more beautiful and simple. It is compatible with laser heads and trimmers. It applies to Windows XP / 7/8/10. It can be used in factories, woodworking, workshops, advertising shops, etc. It is suitable for carving wood, aluminum, brass, organic glass, PCB, MDF, acrylic, resin, nylon, carbon fiber, PVC, etc. Color: Blue and Black. Plug Type: US Standard. Maximum Feeding Height: 115mm/4.53in. Y-axis Travel: 600mm/23.62in. X-axis Travel: 500mm/19.69in. Z-axis Travel: 120mm/4.72in. Y-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. X-axis Transmission: 1605 Roller Screw/15 Square Rail+Slider. Z-axis Transmission: 1204 Roller Screw/15 Square Rail+Slider. Z-axis Drive Motor: 57-76 Stepper Motor. Y-axis Maximum Operating Speed: 1500mm/59.06in/min. Z-axis Maximum Operating Speed: 1200mm/47.24in/min. Spindle Motor Power: Air-cooled 500W. Spindle Motor Speed: 10000RPM. Spindle Motor Collet Model: ER11. Spindle Motor Collet Camping Size: 1-7mm/0.039-0.276. Control System Data Transmission Method: USB. Machine Size: 88.877.355.5cm/34.9630.4321.85in. Workbench Size: 78.4 60.6cm/30.8723.86in. Package Size: 937316cm/36.6128.746.3inch. Gross Weight: 24.3kg/53.57lb. Net Weight: 24kg/52.91 lbs. YSB8SU-000200US(Frame and Machine). Package Size: 8349.524.5cm/49.519.499.65inch. Gross Weight: 24.6kg/54.23lb. Net Weight: 24kg/52.91lb. 1 Air-Cooled Spindle Motor. Other Accessories for Use. Please be patient as all parts arrive. Please allow the slight color difference caused by the shooting light and 1-3 cm error due to manual measurement, and make sure you do not mind before ordering. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Router Engraver Milling Machine. Spindle Motor Collet Model. Spindle Motor Collet Camping Size. Control System Data Transmission Method.