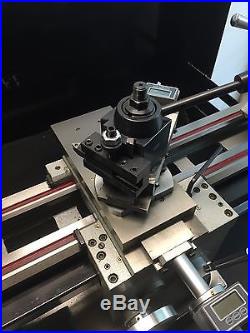

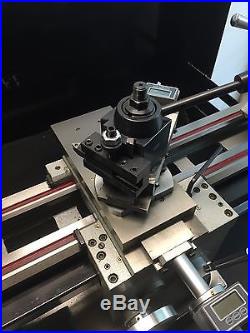

THIS IS YOUR CHANCE TO OWN A COMPLETE MACHINE SHOP SETUP!! If you are interested in gun smithing, prototyping or tinkering these machines can do it all! Plug them in and go! Everything has been meticulously taken care of as is evident in the photos. While building my shop I was also busy building a family – suffice to say I have not had any time to use them. This is your chance to own a great setup that is practically new. I will walk the new owner through all of the machinery. If you have any questions please let me know. Check out my link below for more pictures. 4 axis CNC mill with flood coolant system and mobile stand. 4th axis rotary table with tooling plate, tail stock, and tilting angle plate. Sieg SC6 variable speed lathe with quick change tool post, custom mobile stand and many extras. Grizzly G0561 7×12 metal cutting bandsaw. 580lb capacity 4 drawer rolling cart. BRAND NEW DELL Touchscreen controller Inspiron 19.5 Portable Touch-Screen All-In-One – Intel Pentium – 8GB Memory – 500GB Hard Drive – Windows 10. Software loaded on controller. Custom plexiglass chip guard. 6 precision milling vice. Many end mills (2 and 4 flute, ball). 9 piece Woodruff key set. 10 TTS style precision collets. 12 piece precision R8 collet set. 2 cast iron V-blocks. 2 – 123 setup blocks. Flood coolant nozzles with adjustable magnetic block. Shop fox mobile base. CNC spindle control upgrade kit for SX3/SC6. Grizzly Model H8140 coolant tank. 58 piece clamping kit. Extra zero backlash couplings etc. Quick change tool post with accessories. Brand new boring bar set. Brand new lathe bit set. The mill started out life as a grizzly SX3. I installed a CNC fusion deluxe kit with premium zero backlash ballscrews, Nema23 and Nema34 motor mounts. Angular contact thrust bearings for x and Y axis and zero backlash couplings. I then added a probotix X3 CNC conversion stepper motor driver kit with enclosure which features powerful 420ozin motors for your X- & Y-axis and a 1150ozin motor for your Z-axis and is perfect for your X3 mill conversions. Powerful Z-axis motor eliminates the need for a counter-balance strut. I added the 4th axis (A axis) motor driver and installed limit switches on XYZ a adjustable shop light, Jog pendant, flood coolant, custom flood coolant enclosure, custom built computer arm, tooling plate, 4th axis with tail stock, tilting angle table, tooling plate etc etc. I stripped the mill down and repainted it shop grey. I just finished building the CNC setup and it has only been used for a few test cuts. It runs off Mach 3. Motor: 1 HP, 110V, single-phase, brushless DC. Distance spindle to table: 14-3/4. Collars calibrated: 0.001. Table size: 6-1/4″ x 21-5/8″. Table travel (longitudinal): 15-7/8. Table travel (cross): 5-3/4. Dovetail column with elevation handwheel graduated in 0.0005. Over 14 of headstock movement. Digital spindle scale reads metric or inches, zero set, ON/OFF. Reversing buttons on the spider handles for tapping. Front mounted fine feed knob. Push button motor control for forward, reverse, tapping, and off. 2 x MondoStep 4.2 BiPolar Stepper Motor Driver. 1 x MondoStep 7.8 Bi-Polar Stepper Motor Driver. 2 x Green HT23-420-8 420ozin Stepper Motor (X- & Y-Axis). 1 x HT34-280-8 1150ozin Stepper Motor (Z-Axis). PBX-RF Isolated Parallel Port Breakout Board (Mach3 or LinuxCNC). 40Volt 10Amp Linear Power Supply. 3 x 10 IDC Cables 10-pin. Grizzly Model H8140 flood coolant system enclosed within stand. Custom flood coolant catch tray. Cast aluminum tooling plate 5/8″ thick – 6.3″ x 16″ Holes tapped 3/8″-16. 1 RBX 3-channel opto-isolated relay board for any extra inputs. Seig Super C6 Variable speed (SMITHY MI-921LV 9×21). Swing over bed: 250mm. Distance between centers: 550MM. Hole through spindle: 20mm. Spindle Speed: Variable 125 – 2000 RPM. 0.4MM -3.0MM (12 Thread pitches). 1000W Brushless DC motor. 3 Jaw chuck, MT2 Dead center, Gear set, wrench set, Live center, Chuck. Digital DRO on both Axis. 4 Way tool Turret. Chuck Guard with Auto power-off. Built in spindle speed display. Touch panel controls for speed and direction. Overload protection built into control board. Only used a handful of times to test cut some plastic stock. I added a machine light, a custom welded mobile stand, and a quick change tool post. Everything is variable speed so no messing with gears to change speeds, it’s as easy as pushing a button. I also added the digital DRO option on both axis. The stand started out as a RIGID 48′ storage chest. I welded extra supports on the lid, a chip/coolant catch around the top, adjustable casters (which can be taken off), and tapped secure points. I stripped it down and repainted it with an epoxy black coating. I designed the stand so that the lathe can fit inside of it for transport. Grizzly GO5617 Metal cutting Bandsaw. This is a great bandsaw!! I used it to the cut mild steel for the lathe stand and some aluminum for the CNC mill construction. Works like a champ! This large capacity Metal-Cutting Bandsaw has a small footprint as well as being completely mobile! Designed to cut 7″ round and 7″ X 12 rectangular stock, this machine also features hydraulic downfeed control, coolant system, blade brush and more! Features: Automatic shut-off, Hydraulic feed control. Blade speeds: 90, 135, 195, 255 FPM, Footprint: 13″ x 38″, Coolant capacity: 2-1/2 gal. Blade size: 93″ x 3/4″, Included blade size: 93″ x 3/4″ x 6 TPI, Overall dimensions: 48″L x 16″W x 40H. The item “4 AXIS TOUCHSCREEN CNC MILL/LATHE/METAL CUTTING BANDSAWithMANY EXTRAS” is in sale since Sunday, May 29, 2016. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “easye381″ and is located in Warrenton, Virginia. This item can’t be shipped, the buyer must pick up the item.