2025

Mini Press Precision Table Drilling Machine Portable Benchtop Driller 120W

Mini Drill Press Precision Table Drilling Machine Portable Benchtop Driller CNC 795 Motor B10 Chuck Metal Wooden DIY Crafts Tool. Name: Mini Bench Drill.

Comments Off

Mini Drill Press Precision Table Drilling Machine Portable Benchtop Driller CNC 795 Motor B10 Chuck Metal Wooden DIY Crafts Tool. Name: Mini Bench Drill.

Comments Off

Caste Iron Precision Swivel 3inch Precision Milling Vices(Jaw Width 75 mm)(USA). ? Premium Quality & High Precision- Crafted from high-tensile seasoned cast iron for strength and durability. ? 3 (75 mm) Jaw Width- Ideal for holding a variety of workpieces securely. ? 360° Swivel Base- Graduated in 1-degree increments for precise angle adjustments on the Y-axis. ? Adjustable Tilt Mechanism- Locks at any angle between 0° and 90° for versatile positioning. ? Jaw Specifications- Max Jaw Opening: 78 mm ; Jaw Depth: 35 mm. ? Center Height- 165 mm in the vertical position for optimal alignment. ? Base Dimensions- 195 x 138 mm for a compact and stable footprint. ? Easy Mounting- Mounting Slots PCD: 175 mm; Slot Width: 12.5 mm for secure installation.

Comments Off

Magnet Scale Read Head Sensor 2Axis 3Axis Digital Readout Display Milling Lathe. Through non-contact induction, the linear motion is converted into orthogonal pulse signal output, which can accurately measure the length, acceleration and so on. The shape design is small, the installation is convenient, saves the installation space, the straight line length can reach more than 100 meters. Lathes, Milling Drilling, Grinding Machines. Sheet Metal Working Machines. Output Signal Type: TTL square wave RS422 Line Driver. Output Signals: A, /A, B, /B, Z, /Z. Current: Maximum 30 mA per Channel. Gap Between Tape and Sensor. 2mm is recommended, Max. Repeatbility: +/- 1 Plus. Oerating Temperature range: -10 to + 70 Celsius degrees. Non-contact induction to detect rotation position and speed, no need to worry about mechanical wear. The highest reaction speed is 20m/s, the highest resolution is 0.005mm, and the system precision is ±0.01mm/m. The sensor head is small in size and suitable for small installation space. And high protection grade design (IP67), can be used for oil pollution, cutting, vibration and other harsh environment. In industrial applications, it can avoid the sensitivity of general optical environmental pollution and increase the long-term stability of the system. It’s especially suitable for the facilities: metal processing facilities, stone material machinery. And wood working machine. 1pc digital readout only. 1pc magnet scale &Read Head only. Please contact customer service if you do not agree to cut off.

Comments Off

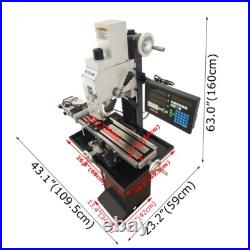

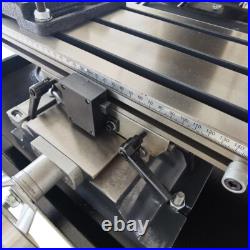

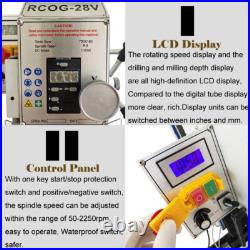

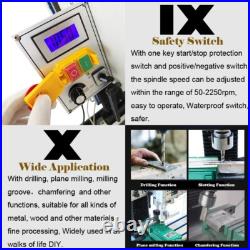

110V 1300W High Precision Metal Drilling and Milling Machine Brushless Drilling Lathe. RCOG-28V multi-functional drilling and milling machine has rich functions, can meet the metal, wood, plastic, Buddha beads and other finishing, all copper brushless motor, strong power, simple operation, durable, high processing accuracy, is the home DIY processing of various parts of the necessary machine. Powerful function: This is a multi-functional drilling and milling machine, can complete drilling and milling operations. Also can be used for precision parts processing, sample processing and model. Three axis grating ruler: Three axis grating ruler includes zero clear, preset, inch/metric display, relative/absolute switch, automatic sub-centers, calculator, power failure memory, RI and other functions, greatly improve the processing efficiency and accuracy! – All metal: It USES an integrated spindle and brass gear, which makes it not only precise but also durable. Variable-Speed: Weather you need high speed or lower speed spindle operations this machine can handle it. Boasting a 20-2250 RPM spindle speed for the extreme precision your project needs. It is important to note that this lathe has only a metric scale. ±90°(The nose can actually rotate 360 degrees). Distance from spindle to table. The Range of spindle speeds. 27.5″7.1″(700mm180mm). 320.8LB(145.5kg)/386.9LB(175.5kg). Product Features & Advantages. Workbench is equipped with a bench clamp, the bench clamp is fixed on the workbench, can be used to clamp a variety of workpiece processing, clamping effect is good, save time and effort. Motor power up to 1300W!! Adopt high quality brushless motor, with overload and overheating protection function; Belt drive, high efficiency, low energy consumption, low noise; Long service life. The head of the machine can be tilted to the left and to the right by loosening the fixing screws of the head of the machine. The tilt Angle range is up to 90°, which is easy for drilling and milling special angles. The rotating speed display and the drilling and milling depth display are all high-definition LCD screens, which are clearer and richer than the previous digital tube display and convenient to operate. Spindle micro feed locking handle, convenient manual control of drilling and milling depth, release the hand can automatically return to the starting position. The processing table is designed behind the drainage hole, through the connection of the hose can be discharged at any time in the process of cooling liquid and excess oil. Axis X Power Feed. Equipped with axis X power feed, can achieve positive and reverse reversing and stepless speed regulation, running more stable, less noise; Greatly improve the machining accuracy and efficiency. Equipped with a three-axis digital display grating ruler, can realize the Angle or length measurement and control; The accuracy reaches 0.005mm, greatly improve work efficiency and machining accuracy. With one key start/stop protection switch and positive/negative switch, the spindle speed can be adjusted within the range of 20-2250rpm, easy to operate; Waterproof switch, safer. With drilling, plane milling, milling groove, chamfering and other functions, suitable for all kinds of metal, wood and other materials fine processing, widely used in all walks of life DIY. Drilling and milling machine 1. Axis X power feed 1. Milling chuck set 1. Drill chuck retaining pin 1. Drill chuck wrench 1. You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

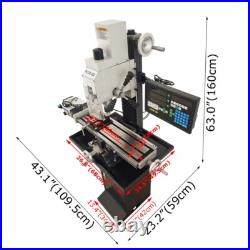

1300W RCOG-28V Brushless Precision Milling and Drilling Machine 110V. RCOG-28V multi-functional drilling and milling machine has rich functions, can meet the metal, wood, plastic, Buddha beads and other finishing, all copper brushless motor, strong power, simple operation, durable, high processing accuracy, is the home DIY processing of various parts of the necessary machine. ±90°(The nose can actually rotate 360 degrees). Distance from spindle to table. The Range of spindle speeds. 27.5″7.1″(700mm180mm). 35.4″22.4″37.8(90cm57cm96cm). 260.1LB(118kg)/313.0LB(142kg). Product Features & Advantages. Powerful function: This is a multi – functional drilling and milling machine, can complete drilling and milling operations. Also can be used for precision parts processing, sample processing and model. Brushless motor:Adopts 1300 watt high power pure copper brushless motor, strong power, can work continuously for a long time; At the same time, the belt drive is used for lower noise. All metal: It USES an integrated spindle and brass gear, which makes it not only precise but also durable. Variable-Speed: Weather you need high speed or lower speed spindle operations this machine can handle it. Boasting a 50-2250 RPM spindle speed for the extreme precision your project needs. It is important to note that this lathe has only a metric scale. Product Presentation & Details. Drilling and milling machine 1. Milling chuck set 1. Drill chuck retaining pin 1. Drill chuck wrench 1. You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

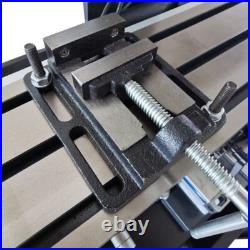

High-precision Metal/Wood Drilling&Milling Machine Bench Brushless Drilling Machine. RCOG-28V multi-functional drilling and milling machine has rich functions, can meet the metal, wood, plastic, Buddha beads and other finishing, all copper brushless motor, strong power, simple operation, durable, high processing accuracy, is the home DIY processing of various parts of the necessary machine. ±90°(The nose can actually rotate 360 degrees). Distance from spindle to table. The Range of spindle speeds. 27.5″7.1″(700mm180mm). 35.4″22.4″37.8(90cm57cm96cm). 260.1LB(118kg)/313.0LB(142kg). Powerful function: This is a multi – functional drilling and milling machine, can complete drilling and milling operations. Also can be used for precision parts processing, sample processing and model. Brushless motor:Adopts 1300 watt high power pure copper brushless motor, strong power, can work continuously for a long time; At the same time, the belt drive is used for lower noise. All metal: It USES an integrated spindle and brass gear, which makes it not only precise but also durable. Variable-Speed: Weather you need high speed or lower speed spindle operations this machine can handle it. Boasting a 50-2250 RPM spindle speed for the extreme precision your project needs. It is important to note that this lathe has only a metric scale. The rotating speed display and the drilling and milling depth display are all high-definition LCD display, Compared to the digital tube display more clear, rich. Display units can be switched between inches and mm. With one key start/stop protection switch and positive/negative switch, the spindle speed can be adjusted within the range of 50-2250rpm, easy to operate, Waterproof switch, safer. Workbench is equipped with a bench clamp, Bench clamp is fixed on the workbench, Can be used to clamp a variety of workpiece processing, clamping effect is good, save time and effort. Motor power up to 1300W!! Adopt high quality brushless motor, with overload and overheating protection function; Belt drive, high efficiency, low energy consumption, low noise; Long service life. The head of the machine can be tilted to the left and to the right by loosening the fixing screws of the head of the machine. The tilt Angle range is up to 90°which is easy for drilling and milling special angles. Spindle micro feed locking handle, convenient manual control of drilling and milling depth, release the hand can automatically return to the starting position. The processing table is designed behind the drainage hole, through the connection of the hose can be discharged at any time in the process of cooling liquid and excess oil. With drilling, plane milling, milling groove, chamfering and other functions, suitable for all kinds of metal, wood and other materials fine processing, Widely used in all walks of life DIY. Drilling and milling machine 1. Milling chuck set 1. Drill chuck retaining pin 1. Drill chuck wrench 1. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

CT125 3-in-1 Micro Multi-function Drilling and milling Lathe Machine Product Description This CT125 3-in-1 Micro Multi-Function Drilling and Milling Lathe Machine adopts cast iron body and all metal gears. It is mainly used for the outer circle, inner hole, end face, taper and metric and inch thread processing of various rotating parts. It is suitable for families, studios, schools, and various small repair workshops. Specification Machine Type: CT125 Power: 180 W Voltage: 110 V Size: 523041 CM/20.511.5816.14IN Wight: 22 KG Package size: 553048 CM/21.711.818.9IN Detailed Product Information 1. Turning Maximum workpiece rotation diameter: 125mm/4.9in Maximum workpiece length: 180mm/7.1in. 180W 180mm Brushless Precision Milling and Drilling Machine 110V Lathe. Ct125 3-in-1 Micro Multi-function Drilling and Milling Lathe Machine. This Ct125 3-in-1 Micro Multi-function Drilling and Milling Lathe Machine Adopts Cast Iron Body and All Metal Gears. It Is Mainly Used for the Outer Circle, Inner Hole, End Face, Taper and Metric and Inch Thread Processing of Various Rotating Parts. It Is Suitable for Families, Studios, Schools, and Various Small Repair Workshops. The Control Panel of the Machine Tool Is Simple and Easy to Operate. The Machine Has High Precision Spindle and Quality Electronic Control System The Bed Saddle Is Easy to Fix Fixtures, Molds, Pliers, and Other Tools. The High-power All-copper Asynchronous Motor Provides Strong Power. Dovetail Rail: the Bed Adopts Dovetail Guide Rail, the Contact Surface Is Larger and More Stable. Three-jaw Chuck: This Machine Has 80mm High Precision Three-jaw Chuck. Drilling and Milling Head: It Can Be Rotated 360°, Raised and Lowered Within a Range of 80mm. Drilling and Milling Gears/Pulleys: Through the V-belt Position, the Drilling and Milling Spindle Can Achieve 10 Kinds Rotate Speed. Compact and Easy to Install. Easy to Operate, No Training Required. This Machine Can Process Various Non-ferrous Metals Such As Titanium, Stainless Steel, Steel, Iron, Aluminum, Copper, and Soft Materials Such As Wood and Nylon. Machine Type: Ct125 Power: 180 W Voltage: 110 V Size: 523041 Cm/20.511.5816.14in Wight: 22 Kg Package Size: 553048 Cm/21.711.818.9in. Maximum Workpiece Rotation Diameter: 125mm/4.9in Maximum Workpiece Length: 180mm/7.1in Maximum Workpiece Rotation Diameter on the Tool Rest: 60mm/2.4in Spindle Through Hole Diameter: 9mm/0.35in Spindle Taper Hole: Mt. 1 Number of Metric Threads Processed: 8 Machining Metric Thread Pitch Range: 0.4-1.5mm/0.02-0.06in Number of Inch Threads Processed: 8 Machining Inch Thread Pitch Range: 0.0028-0.00551 /N Longitudinal Feed Series: 2 Longitudinal Feed of Spindle per Rotary Tool Holder: 0.07-0.14mm/0.003-0.005 Tailstock Sleeve Stroke: 18mm/0.71in Taper Hole of Tailstock Sleeve: Mt. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.

Comments Off

Comments Off

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 400;font-size: inherit}. Title:after{content:’You may like’;color: #FFFFFF}. Cs-list>li:nth-child(n+7){display:none}. Title{margin:0;font-weight: 400;font-size: inherit}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off’;font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid="264392372246"]. Title:after{content:’INTBUYING Milling Machine Shaft Spindle Taiwan Rocker R8 Vertical 545mm’}[data-lid="264392372246"]. Coupon:before{content:’6%’} [data-lid="265683865444"]. Title:after{content:’1100W Brushless Precision Milling and Drilling Machine 110V Lathe Metal Wood’}[data-lid="265683865444"]. Coupon:before{content:’10%’} [data-lid="266047594701"]. Title:after{content:’Brushless Motor Precision Milling Drilling Machine Metalworking Wood Lathe 110V’}[data-lid="266047594701"]. Coupon:before{content:’10%’} [data-lid="264856945613"]. Title:aftercontent:’Techtongda Milling and Drilling Machine 7\\.

Comments Off