2017

Sieg X2 CNC Fusion Mini Mill with Brushless Spindle, Quick Change Tooling + MORE

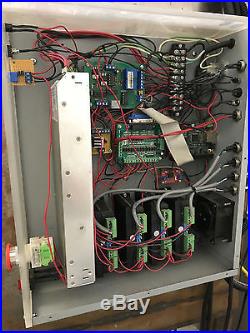

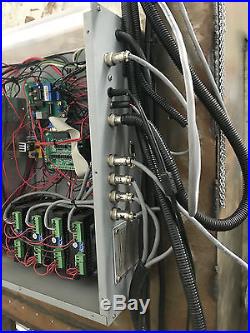

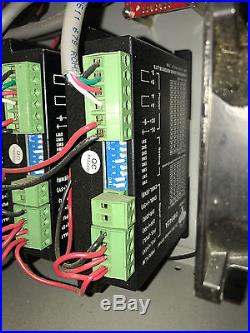

The CNC conversion was done with a CNC Fusion ballscrew kit. The X axis is a 425oz in, Y is 280 oz in, and Z is 420oz in driven by DM542A digital stepper motor drivers. There is a 4th axis driver installed and wired for use with a 4th axis (not included). The spindle is a 500w brushless motor from the LittleMachineShop mini mill/Sieg SX2 and has a pneumatic quick change tool with C3/4 Tormach collet for use with TTS collets or 3/4 shank tools. This is by far the best way to use a CNC machine in my opinion. No messing around with wrenches changing R8 collets. Just push a button and the TTS collet drops out so you can swap it out easily and tool free. Includes rolling enclosure that is set up for flooded coolant. There are two loc line nozzles attached to a magnetic base connected to a submersible pump in a reservoir below the machine. The coolant drains out through a screen back into the reservoir with a secondary catch basin for contaminants/chips. The control box was custom made with an ethernet smoothstepper, 4 DM542A digital stepper motor drivers, a MeanWell 1000W 48V PSU, CNC4PC C6 Spindle control board, and some voltage regulators. There is also a fan installed. There is an e-stop switch on the front as well as a button to release the collet (there’s another button on the spindle head), and a spindle control switch. The spindle can be controlled manually with a knob on the control box or switched to be controlled with the computer through mach. The ethernet smoothstepper is one of the best aspects of this as it means this machine can be used with any computer and there is no need to use one with a parallel port and it supports Mach4. This includes a Windows 7 computer w mach3/cad/cam all ready to go and configured to get using it immediately. Also included is a 1/2″ drill chuck on TTS shank, a 4″ vise with rotating base, USB pendant for jogging etc, clamp kit, and a parallels set. There is also a 38000 rpm pencil grinder attachment on the left side of the spindle for high speed engraving etc. I also installed a tachometer on the face of the spindle to see the RPM of the spindle but never finished it. I can finish it at the buyers request if needed. Feel free to ask any questions you may have. The item “Sieg X2 CNC Fusion Mini Mill with Brushless Spindle, Quick Change Tooling + MORE” is in sale since Saturday, July 15, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “laeauctions” and is located in Los Angeles, California. This item can’t be shipped, the buyer must pick up the item.

Comments Off