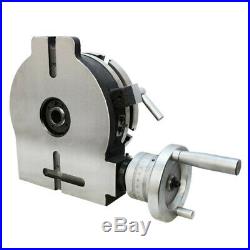

1985 Aciera F1 Precision Universal Milling Machine. In absolute excellent condition both working & cosmetically. One of the rarest and cleanest “barn find” Acieras we’ve ever come across. Original paint and comes loaded with attachments. Absolutely beautiful precision, hard to find Swiss made gem. You will not find another one like this! The spindle is quiet throughout the speed ranges, ways are beautiful & very minimal backlash on the screws. Full description with complete tooling list below. Everything on this machine is in 100% working condition and comes loaded with features. This machine was well taken care of. Backed by our 30-day return privilege. Check out the short video below of the machine under power. ACIERA F1 Precision Universal Milling Machine Demo. Aciera F1 Universal Precision Milling Machine. Longitudinal travel of the table 3.94. Vertical Travel of the Table 5.90. Transverse movement of the headstock 2.95. Graduated feedscrew drums, 1-div. Movement of quill in its housing 1.97. Pitch of feedscrews (mm or tpi) 2mm (10 tpi). Headstock movement , 1-turn of crankhandle. Long movement, 1-turn of crankhandle. Vert movement, 1-turn of crankhandle. Cutter spindle clamping collet, shank dia. Plain Table – horizontal spindle axis. 39″ (Min) to 6.3″ (Max). Plain table – Vertical Spindle Nose distance 0-6.89 max. Plain Table Clamping Area 8.66″ x 3.94″. Collet clamping range, bore dia 1/16″ to 3/8″. Vertical & Horizontal Capability. Welded Steel Cabinet Base with Storage. Standard Vertical Support Spindle. 4.72 Rotary Table Attachment. Rotating 2.16 Vise Attachment. Simple Dividing Head (No indexing arbor). Spindle Dividing Head Center Support. 5C Collet Indexing Head (Non-Aciera). 5C Collet Clamping Fixture (Non-Aciera). Various Table clamping Tools. The milling head is a single unit, including the motor, gear box and cutter spindle. It can be mounted horizontally, or vertically by means of one of the vertical supports; these supports can swivel to left or right and one of them also tilts forwards and backwards. The machine is therefore universal in the true sense of the word. The cutter spindle, with provision for W 12 collets and spindle inserts, is hardened and ground and runs free from play in high precision pre-loaded bearings. The feedscrews are of special steel and have a ground thread. The 3 slides have ground and scraped prismatic-section slideways and any play is taken up by tapered gib-strips. These are some of the features which permit the “toolmaker’s accuracy” of +/. The work-holding accessories, such as the plain table and, by the intermediary of the swivel support, the universal table, the rotary table, the vices and the dividing heads, are mounted on a dove-tail section on the horizontal slide, which permits their displacement along it, and also effectively doubles the horizontal traverse. Fine Feed by Feedscrew or Rapid Feed by Lever. The slides may be traversed either by feedscrews or levers, dependent on the application of the machine. The changeover from one method to the other is effected by clamping or unclamping the feedscrew nuts. The graduated drums read to 0.01 mm. Vertical Compensation by Spring. The vertical slide is equipped with an adjustable compensating spring, which guarantees lightness of vertical traverse irrespective of the load on the table. The above information is to the best of our knowledge from sources deemed reliable, but should be verified at the time of inspection to confirm accuracy. We will help load small items at no charge. Hours: M-F 7:30AM – 4:30PM Saturday by appointment only. By Purchasing equipment from Rohner Machinery Sales, Inc. All Prices are in U. All proposals and acceptances of orders are made with the mutual understanding that orders are not subject to cancellation, and that a deposit is REQUIRED within 7 calendar days or this invoice is invalid. If a hold is desired, a 10% deposit is required to hold machines for up to 30-days. Deposit is non-refundable 14-days after receivable. In no event shall RMS be responsible or liable for special or consequential damages. MACHINE USE & SAFETY. S forms which are different or in addition to the terms herein. S accepting or retaining possession of the goods described on this invoice. The free listing tool. The item “ACIERA F1 Swiss Precision Universal Milling Machine. Loaded. Rare Barn Find” is in sale since Monday, December 16, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “rohnermachinery” and is located in Fullerton, California. This item can be shipped to United States.

- Model: F1

- Country/Region of Manufacture: Switzerland

- Machine Type: Milling Machine

- Model Year: 1985

- Power Source: Electric

- Brand: Aciera

- Control: Manual

- Voltage: 220 V