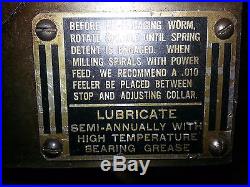

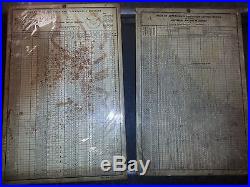

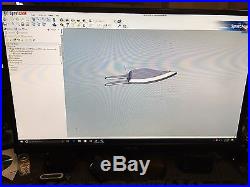

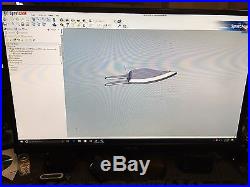

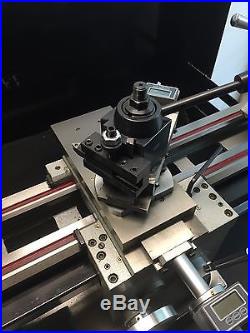

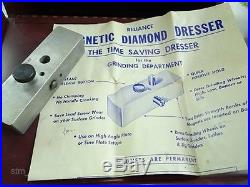

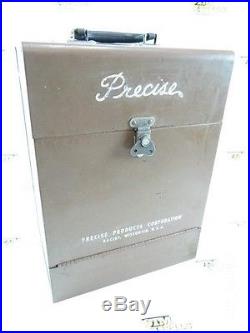

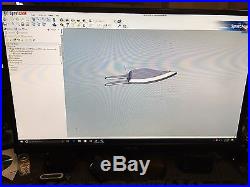

Up for sale we have a Tormach series 3 cnc mill. I’m going to describe it to the best of my ability. Full surround, compressor with hoses, path pilot controller, Sprutcam 10, monitor keyboard mouse jog controller, 1 tormach machinists vise 5 inch, 1 tormach vice set 5 inch (2 vices), Pallet jack, 5 sets of 5x2x1 soft jaws, hard jaws, auto oiler, relocation kit(not installed) custom vent fan, fog buster, height gauge digital, parallel set x2, angle set, adjustable parallel set, 12 er20 tts tool holders, 4 er16 tts tool holders, 2 er32 tool holders some unopened, 123 blocks, 1/2 5/8 indexable endmills shars, 45 degree indexable facemill 2×3/4 shars, flycutter, jobber drill bit set, edge finder, passive touch probe, passive touch probe and tool height custom made, dial indicators, drill chucks various sizes, multiple sets of collets in various sizes, boring bars/heads, inserts for indexable parts (y0101, ybg202, ybc302), clamp set, tts tool racks. Here is the tricky part, the tooling. Carbide endmills and some hss sets. Various size carbide endmills from 3/64-1/2 2 flute , some 3 flute and 4 flute, square end, ball end, 45 degree chamfers, very hard to count them all, a full drawer of just tooling. Tool cart is included as well. All manuals are included, I’m sure I’m missing some things, so ask questions please. I cannot find the time to use it unfortunately. I have already been in contact with tormach, they will need to know when the machine transfers to the new owner. I learned to mill basic things in roughly 2 months time. No prior cnc experience. Great machine and great user help lines. Lots of things on YouTube to help you. I will help disassemble parts to move out of the garage. Once outside, it is yours. A lift gate and a box truck is perfect for this and tie it down. Pallet jack is included so makes it easier. Have roughly 23k investment into everything here. Or cashiers check during bank hours of operation and must clear before loading. If picking up on a Sunday, cash only. I have many more photos if interested in them. Had a good question about if any issues or crashes. I have crashed a few endmills (plunged) but caught before spindle crash. I did however have the spindle door open and went up with the mill, put a dent in upper part of enclosure on the flap not on the main shell. Very minor, thanks for the question. Have a picture if needed. Last picture is a sample of what I milled with the machine. Aluminum stock, flymill finish, engraved with a 3/64 ball end. 45 degree chamfer edges. The item “Tormach CNC Mill 1100 Pathpilot Sprutcam Surround Tooling Endmill Vises Extras” is in sale since Saturday, April 08, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “buzelligolf” and is located in Beecher, Illinois. This item can’t be shipped, the buyer must pick up the item.