2017

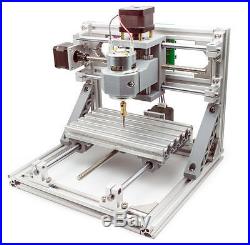

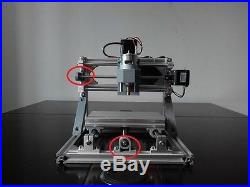

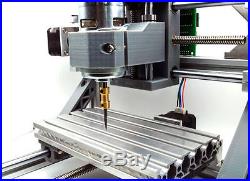

DIY CNC 3 Axis Engraver Machine PCB Milling Wood Carving Router Kit Arduino Grbl

DIY CNC Engraver Machine. The mini CNC engraving machine laser engraving machine is suit for make non- metal processing such as plastic , wood , acrylic , pvc, pcb, wood or the similar material , etc. And airframe adopt profiles + plastic small size, light weight , USB interface , open source GRBL control. The repeat positioning accuracy is with in 0.1mm under no-load, usually is about 0.05mm. Laser is considered no-load. If you use graver, the precision is depending on the hardness of the material. Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328. The controller is written in highly optimized C utilizing every clever feature of the AVR-chips to achieve precise timing and asynchronous operation. It is able to maintain up to 30kHz of stable, jitter free control pulses. It accepts standards-compliant g-code and has been tested with the output of several CAM tools with no problems. Arcs, circlesand helical motion are fully supported, as well as, all other primary g-code commands. Macro functions, variables, and most canned cycles are not supported, but we think GUIs can do a much better job at translating them into straight g-code anyhow. Grbl includes full acceleration managementwith look ahead. That means the controller will look up to 18 motions into the future and plan its velocities ahead to deliver smooth acceleration and jerk-free cornering. The engraver machine couldn’t carve 3 dimensional objects. The different hardness of the material, the different thickness of the carving, and the maximum carving thickness is 30mm. The kit includes xyz stepping motors. Static moment2.2 kg-cm. Motor weight 0.22kg. Body length: 66.7. Front step diameter: 17.4. Front step height: 4.7. Motor Total length: 98. Diagonal assembly hole distance: 28.8. Long assembly hole distance: None. Assembly hole size: M4. Assembly fix hole: 2. And the head travel dimensions of the mini CNC engraving machine laser engraving machine as follow. X: 13cm Y: 10cm Z:7.5cm. Engraver Machine base and Assembly instructions. BAssemble Please note to reserve the nut previously, and kindly refer to below instruction view. CThe aluminum profile are connected as below. DFinal effect: If feel the assembling is smooth, please tighten the screw as possible, so as to keep it fix and stable. Try to assemble on flat place, working table is preferred. BDirect optic axis pedestal assemble instruction: axis separation distance 120mm, which also could be adjusted as users mind. No need to tighten the screw too much, as it has to be adjusted slightly later. ETable assemble instruction view: No need to tighten the screw too much. The nut seat direction could be random. For slide block direction, please refer to below view. FFinal effect: The axis distance could be adjusted according to actual situation. Y axis motor and lead screw assembly. BMotor assembly instruction: Please fix the coupling with the motor, as the motor shaft entering coupling for 12.5mm, then fix by the fastening screw. Fix the motor on motor assemble board, and fix the motor assemble board to the machine. Please note that no need to tighten the screw too much, for convenient adjust later. CScrew assemble instruction. DAssemble screw and coupling. The screw and coupling connecting should be concentric, as the fastening screw should be side by side, and be tightened alternatively. After fix it, manually turn the screw with even speed, and try to feel if the resistance is even. EPlease refer to final effect as below. Portal frame assemble: aPart. BFinal effect: Reserve one nut on the back, for the purpose to assemble the control board, please refer to below view. BInstall XZ assembly. Please refer to below view. Align the edge of optic axis supporting pedestal with top side of aluminum profile, with axis distance 68mm. The assembly requirement is the X axis could move evenly left and right. CPlease refer to final effect as below view. B Please refer to below view for assembly: The distance between portal frame and pedestal tail should be 6mm, the reason for which is the spindle axis and Y axis could coincide. DInstall the assemble board of control board. Open the Device Manager to view the CNC port number: My computer assign is COM3. Console print out the message indicate that the “CNC” is connected successfully. Test whether the X, Y, Z axis movement is normal or not by clicking the control panel on the right side. Note: (1) Please dont set the step too high, otherwise it will be over travel. (2) Please run the program in the machine without engraving knife to get familiar with the operation procedures before installing it. Dont install the engraving knife at first. The engraving knife installation will be explained in following instruction. Open one engraving file for test, and place an acrylic plate on the CNC platform for engraving, which should be fixed well. Start the Spindle of motor, adjust Z axis down, the Step value could be a little higher at the moment. When the engraving knife is going to touch the engraving object, must decrease step Step 0.1, when engraving knife just touch the object surface, set Z axis to be 0. Note: The Spindle must be started before the knife down, otherwise the engraving knife is easily to be broken. At the moment just touch the surface of acrylic, Stop the knife. The work about knife is almost finished. The engraving is finished. The effect after color is added. Control Software is used to control the machine. The item “DIY CNC 3 Axis Engraver Machine PCB Milling Wood Carving Router Kit Arduino Grbl” is in sale since Thursday, August 11, 2016. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “skyluo2013″ and is located in , . This item can be shipped worldwide.

- Brand: Openhapp

- Country/Region of Manufacture: China

- CNC Engraver Machine: 3 Aixs

Comments Off