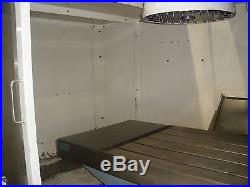

This mini drilling/milling machine with lathe bed can handle most materials. It has a 550watt motor with variable speed drive, The working table with t-slots can enable clamping of workpieces and metric graduated compound scales. The machine also incorporates a tilting column which allows drilling/milling of workpiece at ±90° from vertical. It is supplied with 13mm chuck accessory kit. For adjusting and setting. The lathe bed is made of high grade iron. The rigidity of lathe, the handness and accuracy of the v-slideways are obtained by raw materials, heat hardening and grinding. This machine is DC motor driven. The spindle speed is variable from 20-2500rpm. The feed speed can be adjusted according to the requirements of different workpieces. Replcement of chuck: When replacing the chuck, place a cloth or a piece of wood on the bed way at the bottom of the chuck. This is to avoid damage to the bed way caused by carelessly dropping the chuck. Loosen the 3 set screws to replace the chuck. Replcement of jaws: There are two types of jaws: Internal and external. Please note that the number of jaws fit with the number inside the chuck’s groove. Do not mix them together. When you are going to mount them, please mount them in ascending order 1-2-3, when you are going to take them oit, be sure to take them out in descending order(3-2-1) one by one. After you finish this procedure, rotate the jaws to the smallest diameter and check that the three jaws are well fitted. If you need to reassemble them again as they are not properly assembled. When you are going yo mount the work piece you need only to loosen one jaw. However, we recommend you loosen the three jaws at the same time. In this way you can protect them and will not damage the thread inside. Compound rest adjustment: Loosen the two screws. After you have obtained the angle you desire, please do not forgey to tighten them. Tailstock rest adjustment: When you are going yo change position or replace the tailstock, you need to loosen the nut. Replacement of carbon brushes: Replace the carbon brushed by removing the brush covers both on motor cover. Tool post adjustment: When you are going to asjust the tool post position, you only need to loosen the lever. After you have finished be sure to tighten. If you are going yo replace the work cutter then you need to loosen the screws with the allen wrench provided. Use the chuck to hold the workpiece firmly, and the cutter to start lath’s face cutting(edge of the cutter must be at the same height as the center). By changing the tool post angle and asjustig the compound rest, you can do internal cutting. After asjusting the angle of the compound rest, you can do bevel cutting. Use the chuck to hold the workpiece firmly. Then use the center to fix the other end. If you change the center to drilling chick you can start your drilling immediately. This is a quality mini mill Ideal for the professional engineer or model maker alike. The precision mini lathe is designed to preform various types of processing jobs. Counterface tuming, drilling, threading, and cutting jobs on materials made up of round bar and bar materials can be preformed with this machine. The machine can be used in areas such as mini precision parts processing, sample processing and modeling works. This machine is suitble to use only from 12°C-35°C53.6-95. Head swivels ±90° verticaly. Adjustable gibs on table precision. Adjustable stops on table. Straightforward gear drive mechanism. Extra wide cross table. Chuck Arbor Bolt provides tightening of drilling chuck through the spindle. Rack and pinion feed for drilling operations. Safety guard with microswitch according to EU-requirements. Available in metric leadscrews. START / STOP switch incorporates emergency STOP. Table travel:10/12250/300mm. Cross slide:4″/5″ 100/130mm. Spindle travel:7 180mm. Taper of hole in spindle :MT #3 or R8. Drilling Capacity:1/2 (13mm). End Milling Capacity:5/8 (16mm). Face Milling Capacity:11/8 (30mm). Longitudinal travel: 3.94/10cm. Cross travel: 9.84/25cm. Spindle stroke: 7.87/20cm. Working table size: 18.11″x4.41″/46x11cm. Max distance spindle to table: 8.66/22cm. T-slot: 0.39/1cm. Spindle rotary angle: -45°+45°. Dimension: 14.5″x 26.5″x27/37x67x68cm. 1 X Mini Milling Machine. 1 X Mini milling machine base. 1 X Mini milling machine column. 1 X Tool kit with wrenches. We have warehouses in the USA, UK, DE and AU. For those customers who live in the US, UK, DE, EU and AU, we will send item from the corresponding warehouse. For those customers who live in other countries, we will send item from our foreign warehouses if available, otherwise from China. E-mails are answered Monday through Saturday. Please allow up to 48 hours for a response to your message 3. The item “Mini Milling Drilling Machine With Gear Drive 550W Motor Mill Tool Vertical” is in sale since Saturday, November 11, 2017. This item is in the category “Business & Industrial\Manufacturing & Metalworking\Metalworking Tooling\Equipment Specific Tooling\Milling”. The seller is “warrenau250″ and is located in Ontario, California. This item can be shipped to United States.

- Brand: Unbranded

- MPN: Does Not Apply

- Motor Power: 550W

- Max.table travel: 10″/12250/300mm

- Max.cross slide: 4″/5″ 100/130mm

- Max.spindle travel: 7″ 180mm

- Spindle Speed: L:50-1100rpm H:120-2500rpm

- Taper of hole in spindle: *:MT #3 or R8

- Drilling Capacity: 1/2″ (13mm)

- End Milling Capacity: 5/8″ (16mm)

- Face Milling Capacity: 11/8″ (30mm)

- Longitudinal travel: 3.94″/10cm

- Cross travel: 9.84″/25cm

- Spindle stroke: 7.87″/20cm

- Working table size: 18.11″x4.41″/46x11cm

- Max distance spindle to table: 8.66″/22cm

- Spindle taper: MT3

- T-slot: 0.39″/1cm