2025

5 Axis CNC Kit, Nema 23 57 Closed Loop Step Motor Driver, For machining/Engraving

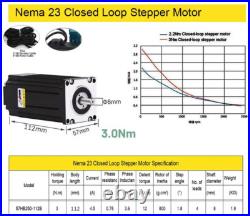

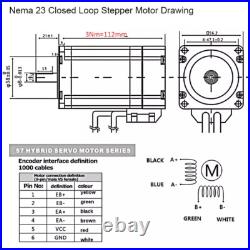

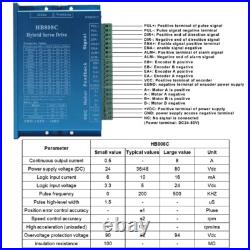

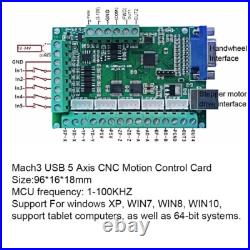

Precision Closed-Loop System: Never Lose Steps:closed-loop stepper motors with 1000-line encoders ensure flawless accuracy, even under heavy loads. High Torque:3Nm holding torque per motor for demanding industrial applications. Advanced DSP Drivers: HB8080C:Nema 23 Closed-Loop Drivers with 13A peak current and 200KHz response frequency for ultra-responsive control. Wide Compatibility: Supports 24-80VDC input, PUL/DIR or CW/CCW signals, and 200-25,600 microsteps for silky-smooth motion. Stable Power Supply: for Nema23:350W 24V DC Output with 90%+ efficiency, over-current/voltage/load protection, and dual AC input (110V/220V switchable). Industrial-Grade Build: Nema 23 closed loop motor size : 3Nm:(57×57×112mm / 2.24×2.24×4.41in). 5 Axis CNC Kit, Nema 23 57 Closed Loop Step Motor Driver, For machining/Engraving. Water Tank Liquid Level Meter. 5 Axis CNC Kit. 5 Closed loop Nema23 stepper Motor. 5 3M Encoder Cable. 5 3M Power Cable. 2 350W 24V power supply. Axis USB Port Mach3 Motion Control Board. 1 x USB cable. 1 x CD disk. Never Lose Steps:closed-loop stepper motors with 1000-line encoders ensure flawless accuracy, even under heavy loads. Holding torque per motor for demanding industrial applications. HB8080C:Nema 23 Closed-Loop Drivers with 13A peak current and 200KHz response frequency for ultra-responsive control. For Nema23: 350W 24V DC Output with 90%+ efficiency, over-current/voltage/load protection, and dual AC input (110V/220V switchable). Nema 23 closed loop motor size. 3Nm:(57×57×112mm / 2.24×2.24×4.41in). Functions of the 5-axis Mach3 Control Board. It supports 5-axis linkage control at most. Strong anti-interference and high reliability. It supports over-current protection, over-voltage protection, position outside the tolerance protection. Perfectly matched components for CNC machines, 3D printers, or automation projects-no compatibility hassles. Durability & Safety. Industrial-grade build with heat-resistant materials and long-term performance stability. Precision milling, engraving, cutting, and lathe operations. Robotic arms, conveyor systems, and assembly lines. 3D Printing & Laser Cutting. High-resolution positioning for flawless layer transitions. Ideal for hobbyists upgrading to professional-grade motion control. Packaging, textile machinery, and rotary indexing systems. Why Choose This Kit? Unmatched Accuracy – Closed-loop technology eliminates step loss. Unlike traditional open-loop systems, which rely solely on command signals without feedback, the closed-loop kit provides real-time position feedback. Resulting in improved accuracy, reliability, and stability. The closed loop stepper motor driver kit boasts features such as precise position control, real-time feedback, and automatic error correction. It ensures reliable and accurate motor performance even in challenging environments. Easy Setup – Pre-matched components save hours of troubleshooting. What are the key features of the closed loop stepper motor driver kit? What are the applications of the closed loop stepper motor driver kit? The closed loop stepper motor driver kit finds applications in various industries requiring precise and reliable motion control, such as CNC machining, 3D printing, robotics, automation, and medical equipment. How does the closed loop stepper motor driver kit compare to traditional open-loop systems? Unlike traditional open-loop systems, which rely solely on command signals without feedback, the closed-loop kit provides real-time position feedback, resulting in improved accuracy, reliability, and stability. We regret that we can not be responsible for any wrong or undeliverable addresses. If you are satisfied with our product, please do the same for us, leave. For us, which means a lot to us, thanks in advance. Do not leave Negative or. Neutral Feedback before Contacting us. We always reply messages. We guarantee against any defective products. We will work on resolving your particular case ASAP.

Comments Off