2026

Electric Lab Crusher Machine 220V Disk Grinder Ore Pulverizer Precision Laborato

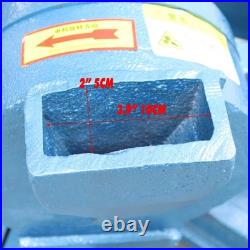

Grinding Disc Crusher Grinding machine. The small disc mill crusher is a piece of high-efficiency equipment specifically designed for grinding and crushing ore materials. By means of its compact structure, flexible operation and stable performance, it is widely used in the scenarios such as laboratory sample preparation, small-scale mining processing and building material testing. It can precisely crush various kinds of ore (such as iron ore, limestone and granite) to meet material processing requirements with different fineness demands. Material of grinding disc: Manganese steel Voltage: 220V 50/60Hz 1PH Motor power: 1500W Driving mode: Belt driving (including a belt cover) Finished product collecting mode: Bottom collecting box Grinding fineness adjusting mode: Use the handwheels to adjust the gap between the grinding discs. Is integrally made of cast iron, stably supports the whole machine, ensures there is no obvious shake during operation and guarantees the grinding precision. Manganese steel grinding disc assembly. Comprises upper and lower manganese steel grinding discs rotating relatively, and is a core part for material crushing. The manganese steel material improves the grinding efficiency and wear resistance. Is composed of a 1.5KW 220V motor, belt pulley and driving belt. After the motor runs, the grinding discs are driven by the belt to rotate so as to grind the material. The belt cover is arranged outside the driving system to avoid the phenomenon that the belt is exposed to cause potential safety hazards. Is composed of an adjusting handwheel, adjusting screw rod and other components. The handwheel can be rotated to drive the screw rod to adjust the gap between the grinding discs, and then the material crushing fineness can be controlled. Is located on the top of the machine. The funnel design is adopted, facilitating material feeding. Meanwhile, the feeding speed can be controlled to avoid the phenomenon that due to too fast feeding, the machine is overloaded. Finished product collecting box. Is installed at the bottom of the machine and abuts against the discharging outlet below the grinding discs. The crushed material automatically falls into the collecting box. The collecting box adopts the pull-out or flip type design, so it is conveniently taken out and cleaned. Installation of collecting box. Operator requirements: Operators must be familiar with the contents of this manual and master the equipment operation methods and safety precautions before they can start working. Non-professionals are strictly prohibited from operating the equipment without authorization, and children are prohibited from touching and operating the machine. Power safety: The equipment must use the 220V single-phase AC power supply that meets the requirements, and the leakage protection device must be installed. It is strictly prohibited to operate the power switch with wet hands to avoid electric shock accidents. When the device is running, it is forbidden to plug or unplug the device. Protective measures: When the equipment operates, the belt cover must be installed in place, and it is strictly prohibited to start the equipment under the condition that the belt cover is not installed or is damaged. It is strictly prohibited to stretch hands or other objects into the feeding inlet, the gap between the grinding discs, and belt driving part to prevent the personal injury. During operation, wear a protective face mask to prevent splashing. Material safety: It is strictly prohibited to feed the too hard materials such as metal blocks and stones, or flammable, explosive or corrosive materials to avoid damaging the equipment or causing safety accidents. The material should be fed slowly and evenly to avoid material blockage in the feeding inlet. After the equipment is completely stopped, the fault should be checked and dealt with. The equipment must not be restarted before the fault is not solved. Equipment placement: The equipment should be placed on a flat and solid ground to avoid tilting and prevent the equipment from falling down during operation. The adequate space should be reserved around the equipment (it is recommended that the space should be no less than 0.5m) for convenient operation, maintenance and heat dissipation. Item included:Grinding Disc Crusher Grinding machine 1 Item Number: 134181. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off