2020

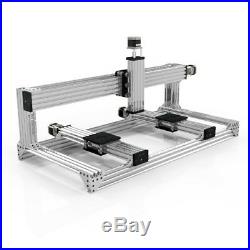

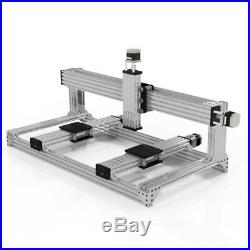

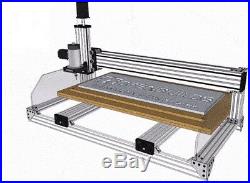

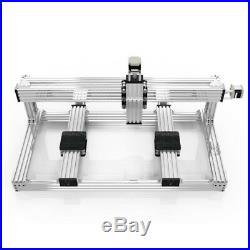

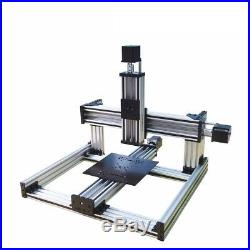

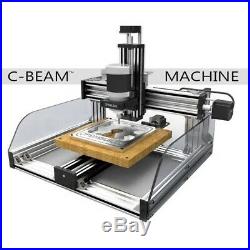

Vico C-Beam Smart 3 Axis CNC Machine Mechanical Kit Screw driven

Vico C-Beam Smart 3 Axis CNC MachineMechanical Kit. Inmany projects it happens, that an off the shelf plate does not suit your needs, a C-Beam machine is the solution to this problem. A C-Beam machine offers thefreedom to create the custom plates you need, right away, no long waits, noextortionate prices. X Axis Travel 350mm – (13.5). Y Axis Travel 280mm – (11). Z Axis Travel 160mm – (6″) Actual working depth is1.250″. Compatible Material for Cutting/Milling. Compared to other Hobby CNC mills and plate makers on themarket, the C-Beam machine is relatively in-expensive. As in the name, the C-Beam machine makes full use of the C-Beam linear rail, which in turn uses the proven to work v-slot profile. Combining the C-Beamlinear rail with other standard parts, allows for easy ACME lead screw linearactuators to be created. Three c-beam linear actuators are used on the C-Beammachine to drive the X, Y and Z axes. With the use of precise ACME lead screws, and anti-backlash nut blocks, highly accurate parts can be manufactured withthe C-Beam machine. To make the CNC kit build even easier, we systematically bagthe parts and label them with their name, quantity and most importantly whatsection of the build they are used on. We have had great feedback using thissystem on our other kits, and it has proven to be well worth the time. What is in the Kit. Our C-Beam mechanical kit includes everything needed tocomplete the mechanical portion of the C-Beam machine. In addition to this wehave the option to include 3 x NEMA23 Stepper Motors. You can be confident onthe quality of the parts we supply in the CNC kit because they are all genuineOpenbuilds. The main components not included, which are needed to get theC-Beam machine cutting and running is MDF boards, Power supply, Controller board, and Router. The C-Beam and V-Slot linear rails are pre-cut. And the ACMELead screws provided are to the correct length. The item “Vico C-Beam Smart 3 Axis CNC Machine Mechanical Kit Screw driven” is in sale since Saturday, September 15, 2018. This item is in the category “Business, Office & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “vico-cnc” and is located in Hull. This item can be shipped worldwide.

- Brand: Vico C-Beam Smart

Comments Off