2021

Haas Vf-3b Vertical Machining Center Tsc Gear Head 4th Axis Cnc MILL Vf Ss

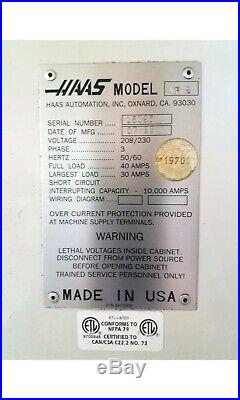

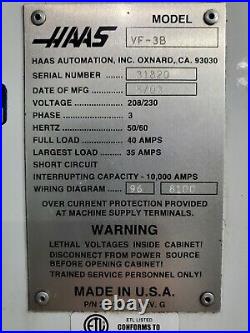

Financing Available at Low Rates. New & Used CNC Machines. CNC LATHE / TURNING CENTERS. HAAS VF- 3B VERTICAL MACHINING CENTER. We are a stocking dealer of New & Used Machine Tools located in Southern California & are members of the MDNA. We have thousands of different Manual, CNC Machines and Tooling in stock for both fabrication & metal cutting. All specifications are approximations, and are subject to verification. 7500 RPM Gear Head Spindle. 24 Side Mount Automatic tool changer. 1000 inch per minute rapids. Brushless-type servo drive motors on all axis. Rapid Traverse Rates: 1000 Inch Per Minute. Cutting Feed Rates: 630 Inch Per Minute. Spindle Nose to Table Min. Number of Std T-Slots: 5. Max Weight on Table: 3500 lbs. Speed Range:7500 RPM. Spindle Power: 20 HP. Max Tool Weight: 12 lbs. Max Tool Dia: 3.6. Max Tool Length: 11. Tool Changing Time: 2.2 Seconds. Air Required: 100 psi, 4 scfm. Power: 220v / 66FLA / 3-Phase. Overall Dimensions: 120″ x 96″ x 100 High. No Charges for loading at list Price. Comes as shown in pictures. MachineStation is a full service CNC Machinery Dealership located in Chino, California, USA. Talk to one of our Machinery experts to get a price quote and more information. We pay cash for your used CNC machinery and Equipment. We are looking forward to being of service to you and your esteemed Organization. Leasing/Loan can be arranged through our financing partners & Banks. For Transportation of the CNC Machinery and Heavy Equipment Flat Bed Service. We load all the machines free of charge from our Warehouses. We can setup LTL or Dedicated trucking loads for at the most competitive prices. We load onto flatbed air ride trucks free of charge at our location. We crate or containerize your machine according to your requirement for Exports. This service is extra depending on the size of Equipment or the number of machines loaded into the container. MachineStation Usa is a global trading company located in California, USA. Used Machine Dealer focused in All Kinds of CNC & Manual Metalworking machines. The item “HAAS VF-3B VERTICAL MACHINING CENTER TSC GEAR HEAD 4TH AXIS CNC MILL VF SS” is in sale since Tuesday, June 22, 2021. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “machinestationusa” and is located in Houston, Texas. This item can be shipped to United States.

- Model: HAAS VF-3B

- Spindle Horsepower: 30 hp

- Country/Region of Manufacture: United States

- Machine Type: Machining Center

- Table Length: 40 in – 59.9 in

- Max Spindle Speed (RPM): 7501 – 10000

- Model Year: 2004

- Power Source: Electric

- X-Axis Travel Bed: 36 in – 40 in

- Y-Axis Travel Bed: 16 in – 20 in

- Z-Axis Travel Bed: 16 in – 20 in

- Spindle Taper: CAT 40

- Function: Drilling

- Brand: Haas

- Table Width: 15 in – 19.9 in

- Control: CNC

Comments Off