2025

Colorful Single Edged Milling Cutter Hycnc Engraving Machine Accessories

Comments Off

USED TABLE ONLY IF YOU NEED OTHER PARTS WE CAN DISCOUNT. NEEDS CLEANING IN EXCELLENT SHAPE.

Comments Off

Well Index 700 2HP Vertical Knee Milling Machine 230/460V 3PH No Powerfeed. Please reference this SKU number when making inquiries. Tested and works as it should. 48″ x 9″ Overall Table. Does not have any motors for powerfeed axis. Has almost zero play on all the axis Very tight controls. BULLSEYE INDUSTRIAL SALES, LLC. Bullseye Industrial Sales is proud to be a dedicated supplier to the manufacturing industry. We are a leading source for quality new and used equipment. We understand that keeping your equipment running is vital keeping your customers happy and we can provide equipment or replacement parts to get your machine or next project back on schedule. We get hundreds of items in daily, if we don’t have it today check back tomorrow. Next Day & Second Day Air Services are available. We choose the carrier. Will there be a dock or forklift. Please make sure that we have the BOL. Prefer to pick it up yourself? You are welcome to do so, by appointment. We will load it free of charge unless otherwise stated in the listing. After the return period has ended, you can no longer return the product. Unless otherwise specifically agreed to in writing by. All goods are so “AS IS’ and “WITH ALL FAULTS meaning, without limitation, that. Which extend beyond the description of the goods on the face hereof; and.

Comments Off

THE GOOSENECK SECTION IS ABOUT 36 APPROX. THERE ARE MEASUREMENTS IN THE PICTURES. CHECK OUT MY OTHER LISTINGS. NO WARRANTIES GIVEN OR IMPLIED. International Buyers – Please Note. I do not mark merchandise values below value or mark items as “gifts” – US and International government regulations prohibit such behavior.

Comments Off

For sale is an unusual Sheldon milling machine attachment as shown. It shows signs of its age but appears to be in good condition and the spindle and drive shaft spin smoothly with no play in the gears. If there are additional tests or measurements that would be helpful just ask. Check out my other listings for more tooling.

Comments Off

As shown in pictures. The bar in the last picture is 3 3/4″L x 3/8″W.

Comments Off

Right Angle Curved Plate Machining Fixed Plate 90 Degree Right Angle Machine. Otherwise we can’t guarantee the package would arrive smoothly. Return accepted in 30 days after you receive the item. Return package must be in the original packaging, item must be in new condition.

Comments Off

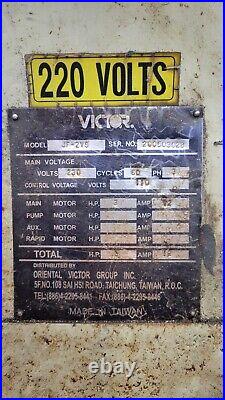

Model JF-2VS, Serial # 200503028, 220V 3 phase power required. This is a running mill removed from production to add a bigger mill. Riser block has been added for extra height. This part can be easily removed if not wanted. Comes equipped with a DRO and rapid travel. Uses R8 collets same as Bridgeport. She could use a deep cleaning but I do not want to invest the time in order to keep the sell price as low as possible. Currently inside shop in Pineville NC. Overhead bridge crane for easy loading on trailer.

Comments Off

See all pictures for the best description. Check out my other listings as well. Thank you for looking.

Comments Off

RCOG-25V Brushless Motor Drilling Milling Machine R8 Multi-function Drilling Machine. RCOG-25V multi-functional drilling and milling machine has rich functions, can meet the metal, wood, plastic, Buddha beads and other finishing, all copper brushless motor, strong power, simple operation, durable, high processing accuracy, is the home DIY processing of various parts of the necessary machine. Powerful function: This is a multi – functional drilling and milling machine, can complete drilling and milling operations. Also can be used for precision parts processing, sample processing and model. Three axis grating ruler: Three axis grating ruler includes zero clear, preset, inch/metric display, relative/absolute switch, automatic sub-centers, calculator, power failure memory, RI and other functions, greatly improve the processing efficiency and accuracy! – All metal: It USES an integrated spindle and brass gear, which makes it not only precise but also durable. Variable-Speed: Weather you need high speed or lower speed spindle operations this machine can handle it. Boasting a 50-2250 RPM spindle speed for the extreme precision your project needs. It is important to note that this lathe has only a metric scale. ±90°(The nose can actually rotate 360 degrees). Distance from spindle to table. The Range of spindle speeds. 27.2″7.1″(690mm180mm). Milling machine:276.7LB(125.5kg)/342.8LB(155.5kg) Supporting base:17.6LB(8kg)/22.0LB(10kg). Axis X power feed voltage. Axis X power feed Power. Axis X power feed speed range. Precision of grating ruler. Product Features & Advantages. Workbench is equipped with a bench clamp, the bench clamp is fixed on the workbench, Can be used to clamp a variety of workpiece processing, clamping effect is good, save time and effort. Motor power up to 1100W!! Adopt high quality brushless motor, with overload and overheating protection function; Belt drive, high efficiency, low energy consumption, low noise;Long service life. The head of the machine can be tilted to the left and to the right by loosening the fixing screws of the head of the machine. The tilt Angle range is up to 90°which is easy for drilling and milling special angles. The rotating speed display and the drilling and milling depth display are all high-definition LCD screens, which are clearer and richer than the previous digital tube display and convenient to operate. Spindle micro feed locking handle, convenient manual control of drilling and milling depth, release the hand can automatically return to the starting position. The processing table is designed behind the drainage hole, through the connection of the hose can be discharged at any time in the process of cooling liquid and excess oil. Axis X Power Feed. Equipped with axis X power feed, can achieve positive and reversereversing and stepless speed regulation, running more stable, less noise; Greatly improve the machining accuracy and efficiency. Equipped with a three-axis digital display grating ruler, can realize the Angle or length measure mentand control, The accuracy reaches 0.005mm, Greatly improve work efficiency and machining accuracy. With one key start/stop protectionswitch and positive/negative switch, the spindle speed can be adjustedwithin the range of 50-2250rpm, easy to operate, Waterproof switch, safer. With drilling, plane milling, milling groove, chamfering and otherfunctions, suitable for all kinds ofmetal, wood and other materialsfine processing, Widely used in allwalks of life DIY. Drilling and milling machine 1. Axis X power feed 1. Milling chuck set 1. Drill chuck retaining pin 1. Drill chuck wrench 1. You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.

Comments Off

Tags: brushless, drilling, drilling110v, machine, milling, motor, multi-function, rcog-25v