2025

US? 3D Trigger Edge Finder To Find CNC Three-Coordinate Touch Probe Tool Setting

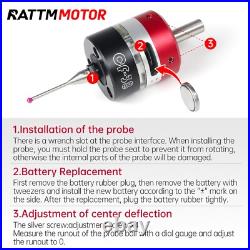

US? 3D Trigger Edge Finder To Find CNC Three-Coordinate Touch Probe Tool Setting. 1 x 3D Precision Tool Setting. Ps: our package does not include the. CR1632 3V button battery. Product Name: Trigger 3D Edge Finder. Item model number: CF-38. Repeat positioning accuracy:? 0.005. Probe direction: ±X ±Y +Z. Probe safety stroke: X. Y plane ±20°, Z direction +2.5mm. Trigger life:? 3 million times. With multiple waterproof and dustproof designs for the product, making it more reliable to use. Equipped with tungsten steel probe and ruby probe tip. Key components are treated with gold plating to extend their service life. Installation of the probe. There is a wrench slot at the probe interface. When installing the probe, you must hold the probe seat to prevent it from rotating, otherwise the internal parts of the probe will be damaged. Adjustment of center deflection, the silver screw is the adjustment screw × 4. Use a dial gauge to measure the runout of the probe ball and adjust the runout to 0. Compact size and good packaging. The 3D trigger edge finder is a high-precision and multifunctional measuring instrument, with a very compact structure and extremely convenient operation. Small size to meet more customer equipment needs. The shockproof cotton in the packaging box effectively protects the probe, and the probe tip is separately packaged in a transparent box to prevent damage during transportation. 1x V5 3D touch probe edge finder. 1x Stainless steel probe tip. 1x Storage box for storing probe. ? Function? The DIYO three-coordinate probe can realize quick centering, edge finding, center finding, shape measurement and other functions by connecting the CNC to the knife edge, which greatly;Repeatability Accuracy: 0.01 mm/ 0.0004 in. Solves the trouble of positioning the workpiece during the second clamping during the machining process. ? Supported software? Adapt to various control panels such as grbl control panel and Mach3. ? 3 wires? NPN-NO 3 wires: Red-VCC (DC5-24V power);Yellow: IO/ Signal Output;Black- GND(DCM); Indicator light: green light when power on, red light after triggering. ? Material of the probe? The shell is made of fine frosted black oxidized aluminum alloy with a flat surface anti-roll design. ? Material of the stylus? The probe tip/stylus is machined from stainless steel up and down, and the ball head is made of tungsten steel ball, which has the advantage of wear resistance. Please measure and adjust it by yourself after receiving the goods. Be sure to use ER11 spring chucks of AAA or above, otherwise the concentricity of the probe tip will be affected. The feature of waterproof and dustproof greatly extends the service life of the probe. Our product comes with a storage box. The shockproof cotton in this storage box protects the probe well, and also avoids collisions and scratches during transportation. The probe tip is machined from stainless steel up and down, and the ball head is made of tungsten steel ball, which has the advantage of wear resistance. NPN-NO 3 wires: Red-VCC (DC5-24V power);Yellow: IO/ Signal Output;Black- GND(DCM). Repeatability Accuracy: 0.01 mm/ 0.0004 in. Approach Direction: ±X, ±Y, +Z. Over Travel Protection Distance: X- ± 4mm/0.16 in, Y- ±4mm/ 0.16 in,, Z- 2mm/ 0.08 in. Lifetime: > 3 million triggers. Yellow: IO/ Signal Output. Indicator light: green light when power on, red light after triggering. Software Recommendation for 3D Probe (We do not provide software). If you are using a mach3 system, it is recommended to use the open source Probe Wizard. If you are using the grbl system, it is recommended to use Grblgru. Need to turn on the spindle speed? Never, never, never, definitely no. How to distinguish the three wires? The red wire is VCC, the black wire is GND, and the white wire is IO. Why is the concentricity different every time the probe is installed? Because your ER chuck spring clip cannot ensure 100% uprightness. Every time the probe is installed, even if the concentricity is adjusted to 1 wire, there will still be deviations when the probe is removed and installed again. Problem&Feedback Please give us the opportunity to resolve any problem when you have, we concern your problem and we will try our best to resolve it. Item must be in it’s original condition and no physical damage.

Comments Off