2025

DDCSV4.1 4 Axis Offline Control Box System with MPG Handwheel for CNC Rounter

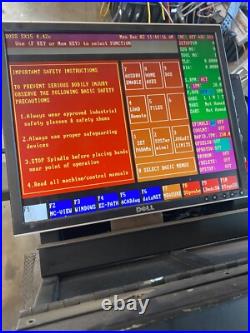

Price Includes: DDCS V4.1 4Axis Offline Control Box as Picture Shown MPG Handwheel as Picture Shown Hardware Configuration inside this Control Box: 1x DDCSV4.1 Controller 1x MC MPG 1x MC Power Supply S800-36V 1x MC Power Supply LRS-75-24 1x MC VFD 2.2KW 110V/220V 4x HBS57S Stepper Driver 1x MC Plug-in Filter CW4L2-20A 1x MC Wire-lead Filter CW1B-10A 1x MC 4-channel relay-24V 1x MC Fan 8025-24V 2x MC Fan 6010-24V 1x MC DB37 Terminal Block Tips: Most Internal cables and modules inside this control box have been pre-connected, just follow our instruction to simply plug this box and it can work for your machine! DDCSV4.1 4 Axis Offline Control Box System with MPG Handwheel for CNC Rounter. DDCS V4.1 4Axis Offline Control Box System with MPG Handwheel. The BulkMan3D B-PRO DDCSV4.1 Industrial-gradeController Box is a high-performance control system specially designed to meet the needs of industrial manufacturing. Its rugged exterior and state-of-the-art technology ensure precise control of all CNC machine functions. The DDCS V4.1 is a standalone/offline controller, supports comprehensive Fanuc G code set file and can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller, no size limited of the G-code file. The G-code design supports various software of CAD/CAM, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on. Meet the needs of various CNC machines: Engraving machines, Milling machines, Routers, Cutting. Etc. We Recommend this DDCSV4.1 offline Control Box for our OXMAN. And Ultiamte Bee CNC. DDCS V4.1 4Axis Offline Control Box as Picture Shown. MPG Handwheel as Picture Shown. Hardware Configuration inside this Control Box. 1x DDCSV4.1 Controller. 1x MC Power Supply S800-36V. 1x MC Power Supply LRS-75-24. 1x MC VFD 2.2KW 110V OR 220V. 4x HBS57S Stepper Driver. 1x MC Plug-in Filter CW4L2-20A. 1x MC Wire-lead Filter CW1B-10A. 1x MC 4-channel relay-24V. 1x MC Fan 8025-24V. 2x MC Fan 6010-24V. 1x MC DB37 Terminal Block. Tips: Most Internal cables and modules inside this control box have been pre-connected, just follow our instruction to simply plug this box and it can work for your machine! 220V Offline Control Box Product Details. 110V Offline Control Box Product Details. Terms of Sale (VAT). Return must include all original package and accesorries, item must in good condition. We will work with you to until you are satisfied. We will try our best to solve your problem to your satisfaction. We are always here with you! Our working time is 8 :30AM – 6:30PM from Monday – Friday.

Comments Off