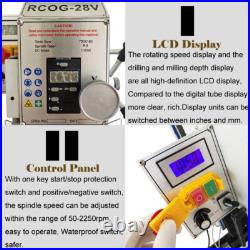

CT125 3-in-1 Micro Multi-function Drilling and milling Lathe Machine Product Description This CT125 3-in-1 Micro Multi-Function Drilling and Milling Lathe Machine adopts cast iron body and all metal gears. It is mainly used for the outer circle, inner hole, end face, taper and metric and inch thread processing of various rotating parts. It is suitable for families, studios, schools, and various small repair workshops. Specification Machine Type: CT125 Power: 180 W Voltage: 110 V Size: 523041 CM/20.511.5816.14IN Wight: 22 KG Package size: 553048 CM/21.711.818.9IN Detailed Product Information 1. Turning Maximum workpiece rotation diameter: 125mm/4.9in Maximum workpiece length: 180mm/7.1in. 180W 180mm Brushless Precision Milling and Drilling Machine 110V Lathe. Ct125 3-in-1 Micro Multi-function Drilling and Milling Lathe Machine. This Ct125 3-in-1 Micro Multi-function Drilling and Milling Lathe Machine Adopts Cast Iron Body and All Metal Gears. It Is Mainly Used for the Outer Circle, Inner Hole, End Face, Taper and Metric and Inch Thread Processing of Various Rotating Parts. It Is Suitable for Families, Studios, Schools, and Various Small Repair Workshops. The Control Panel of the Machine Tool Is Simple and Easy to Operate. The Machine Has High Precision Spindle and Quality Electronic Control System The Bed Saddle Is Easy to Fix Fixtures, Molds, Pliers, and Other Tools. The High-power All-copper Asynchronous Motor Provides Strong Power. Dovetail Rail: the Bed Adopts Dovetail Guide Rail, the Contact Surface Is Larger and More Stable. Three-jaw Chuck: This Machine Has 80mm High Precision Three-jaw Chuck. Drilling and Milling Head: It Can Be Rotated 360°, Raised and Lowered Within a Range of 80mm. Drilling and Milling Gears/Pulleys: Through the V-belt Position, the Drilling and Milling Spindle Can Achieve 10 Kinds Rotate Speed. Compact and Easy to Install. Easy to Operate, No Training Required. This Machine Can Process Various Non-ferrous Metals Such As Titanium, Stainless Steel, Steel, Iron, Aluminum, Copper, and Soft Materials Such As Wood and Nylon. Machine Type: Ct125 Power: 180 W Voltage: 110 V Size: 523041 Cm/20.511.5816.14in Wight: 22 Kg Package Size: 553048 Cm/21.711.818.9in. Maximum Workpiece Rotation Diameter: 125mm/4.9in Maximum Workpiece Length: 180mm/7.1in Maximum Workpiece Rotation Diameter on the Tool Rest: 60mm/2.4in Spindle Through Hole Diameter: 9mm/0.35in Spindle Taper Hole: Mt. 1 Number of Metric Threads Processed: 8 Machining Metric Thread Pitch Range: 0.4-1.5mm/0.02-0.06in Number of Inch Threads Processed: 8 Machining Inch Thread Pitch Range: 0.0028-0.00551 /N Longitudinal Feed Series: 2 Longitudinal Feed of Spindle per Rotary Tool Holder: 0.07-0.14mm/0.003-0.005 Tailstock Sleeve Stroke: 18mm/0.71in Taper Hole of Tailstock Sleeve: Mt. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.