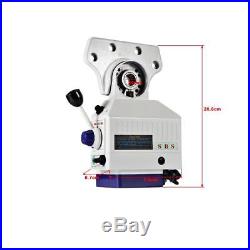

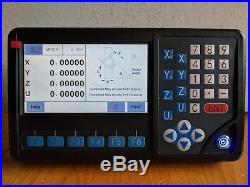

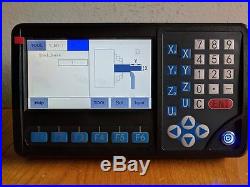

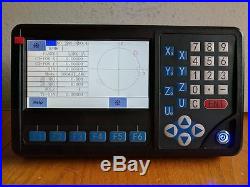

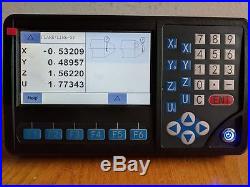

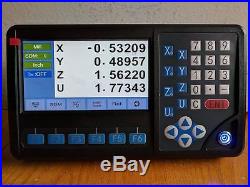

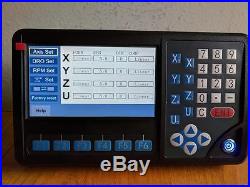

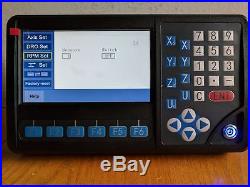

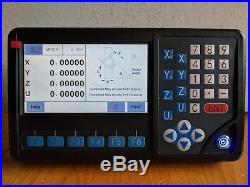

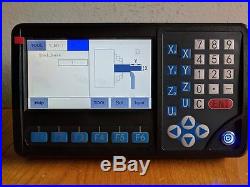

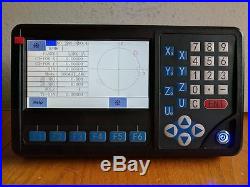

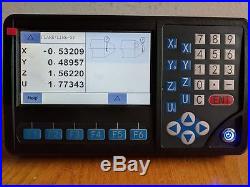

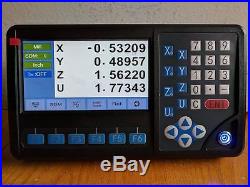

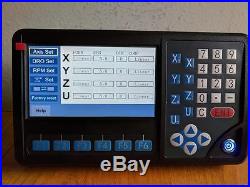

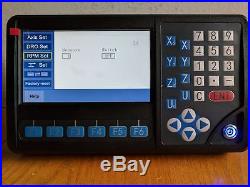

Replaces most top name DRO Displays. Welcome to some of the most user friendly, reliable and affordable DRO you will find anywhere! For the price you will find that these will stand up with any of the. Big name Brands on the market today, at half the cost. They have stood up to the test of time – with many satisfied customers already. These units are simply the best in terms of quality, value and functionality. Check out Toolmann Machinery Sales Store for. Kits that come complete with high precision Glass Linear Scales and mounting hardware. Kit can be set up at this price for machines from: 2″ to 40″travels on Machine Tools. All in one model can be switched between Mill, Lathe, and Grinder. Let us put a Kit together for you today, just send travels & machine type. Display supports 0.1um-10 um scales as well. Can be switched between Mill, Lathe, Grinder and EDM. Supports both English and Metric units (in/mm display). Absolute and Incremental measuring mode. Center line (1/2) function – Sub datum (200 points). Tool library (200 points). Linear drilling function Mill Mode. Bolt circle (PCD) machining in Mill Mode. Incline and oblique plane machining Mill Mode. Simple and Smooth Radius machining Mill Mode. Asymptotic machining of inner cavity (cambering) Mill Mode. Radius/Diameter function in Lathe mode. Taper function in Lathe mode – Axis summing in Lathe mode. Filter in Grinder mode. Linear and non-linear error compensation. Auto Zero/reference function – Calculator with trigonometric functions. Sleep Mode – Power Off memory. 100-240V, 50/60Hz universal AC power. Mounting Arm and hardware included. Toolmann is a US company and we stand behind our products. This item is GUARANTEED against DOA. Defective items will be replaced upon receipt and completion of manufacturers inspection process. Defects caused by improper installation, abuse, physical damage, and normal tear and wear are not covered. The item “DRO readout Display 4-axis replacement unit interfaces with other mfg” is in sale since Tuesday, May 23, 2017. This item is in the category “Business & Industrial\Heavy Equipment Parts & Accs\Manufacturing Equipment Parts\Digital Readouts”. The seller is “toolmannmachinery” and is located in Oshkosh, Wisconsin. This item can be shipped to United States, Canada, United Kingdom, Denmark, Romania, Slovakia, Bulgaria, Czech republic, Finland, Hungary, Latvia, Lithuania, Malta, Estonia, Australia, Greece, Portugal, Cyprus, Slovenia, Japan, China, Sweden, South Korea, Indonesia, Taiwan, South africa, Thailand, Belgium, France, Hong Kong, Ireland, Netherlands, Poland, Spain, Italy, Germany, Austria, Israel, Mexico, New Zealand, Philippines, Singapore, Switzerland, Norway, Saudi arabia, Ukraine, United arab emirates, Qatar, Kuwait, Bahrain, Croatia, Malaysia, Chile, Colombia, Costa rica, Panama, Trinidad and tobago.

- Brand: Protech

- Type: Digital Readout

- Model Year: 2017

- Equipment Type: Machines

- Equipment Make: Protech

- Axis: 4 Axis

- MPN: 0700-02

- Compatible Equipment Type: EDM

- Compatible Equipment Make: ACURITE

- Model: P700-4V