2018

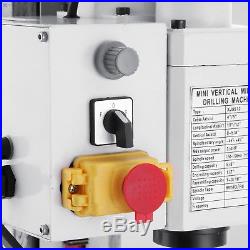

Robust construction MINI DRILLING & MILLING MACHINE 550W VARIABLE SPEED MT3

550W Variable Speed Milling Mill Machine Precision Vertical Turret Milling Machine. This mini drilling/milling machine with lathe bed can handle most materials. It has a 550watt motor with variable speed drive, The working table with t-slots can enable clamping of workpieces and metric graduated compound scales. The machine also incorporates a tilting column which allows drilling/milling of workpiece at ±90° from vertical. It is supplied with 13mm chuck accessory kit. For adjusting and setting. The lathe bed is made of high grade iron. The rigidity of lathe, the hand. Ness and accuracy of the v-slideways are obtained by raw materials, heat hardening and grinding. This machine is DC motor driven. The spindle speed is variable from 20-2500rpm. The feed speed can be adjusted according to the requirements of different workpieces. When replacing the chuck, place a cloth or a piece of wood on the bed way at the bottom of the chuck, which helps to avoid damage to the bed way caused by carelessly dropping the chuck. Loosen the 3 set screws to replace the chuck. There are two types of jaws: Internal and external. Please note that the number of jaws fit with the number inside the chuck’s groove. Do not mix them together. When you are going to mount them, please mount them in ascending order 1-2-3, when you are going to take them out, be sure to take them out in descending order(3-2-1) one by one. After you finish this procedure, rotate the jaws to the smallest diameter and check that the three jaws are well fitted. If you need to reassemble them again as they are not properly assembled. When you are going yo mount the work piece you need only to loosen one jaw. However, we recommend you loosen the three jaws at the same time. In this way, you can protect them and will not damage the thread inside. Loosen the two screws. After you have obtained the angle you desire, please do not forgey to tighten them. When you are going yo change position or replace the tailstock, you need to loosen the nut. Replacement of carbon brushes. Replace the carbon brushed by removing the brush covers both on motor cover. Tool post adjustment: When you are going to a. Just the tool post position, you only need to loosen the lever. After you have finished be sure to tighten. If you are going yo replace the work cutter then you need to loosen the screws with the allen wrench provided. Use the chuck to hold the workpiece firmly. Then use the center to fix the other end. If you change the center to drilling chick you can start your drilling immediately. Use the chuck to hold the workpiece firmly, and the cutter to start lath’s face cutting(edge of the cutter must be at the same height as the center). By changing the tool post angle and a. G the compound rest, you can do internal cutting. Justing the angle of the compound rest, you can do bevel cutting. This is a quality mini mill Ideal for the professional engineer or model maker alike. The precision mini lathe is designed to preform various types of processing jobs. Ming, drilling, threading, and cutting jobs on materials made up of round bar and bar materials can be preformed with this machine. The machine can be used in areas such as mini precision parts processing, sample processing and modeling works. This machine is suit. Ble to use only from 12°C-35°C. Head swivels ±90° vertical. Adjustable gibs on table precision. Adjustable stops on table. Straightforward gear drive mechanism. Extra wide cross table. Chuck Arbor Bolt provides tightening of drilling chuck through the spindle. Rack and pinion feed for drilling operations. Safety guard with microswitch according to EU-requirements. Available in metric leadscrews. START / STOP switch incorporates emergency STOP. Drilling capacity: 13mm /0.51. Face milling capacity: 30mm /1.18. End milling capacity: 16mm/0.63. Longitudinal travel: 100mm/3.94. Cross travel: 250mm /9.84. Spindle stroke: 200mm /7.87. Working table size: 460X 112mm/18.11″x4.41″. Max distance spindle to table: 220mm /8.66. T-slot: 10mm /0.39. Spindle speed: 20 – 2500rpm. Spindle rotary angle: -45°+45°. Dimension: 368X673X685mm /14.5″x 26.5″x27. Size: 460110mm/18.11″x4.33″. Mini milling machine powertrain. 1 X Tool kit with wrenches. 1 X Mini milling machine base. Mini milling machine column. Sign up to newsletter. As a leading and emerging company in manufactory and exporting business, we are specialized in Business and Industrial Products, Sporting Goods, Pet Products, Home and Garden products for more than 10 years. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. If you have any changes, pls inform us. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Leave a Message if. You want to cancel an order. If you need further assembly instructions for a product. Any other unspecified questions or concerns. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. A: The item ships from Rancho Cucamonga, CA, United States. A: Please log on your account. Q: How do I return an item? Please contact our customer service before you return an item. The item “Robust construction MINI DRILLING & MILLING MACHINE 550W VARIABLE SPEED MT3″ is in sale since Tuesday, August 21, 2018. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\CNC & Metalworking Supplies\Equipment Specific Tooling\Milling”. The seller is “rapidly-666″ and is located in gz. This item can be shipped worldwide.

- Brand: VEVOR

- MPN: LXQIC00241505877746

- Model: MINI MILLING DRILLING MACHINE

- Country/Region of Manufacture: China

- Motor power: 550W

- Drilling capacity: 13mm /0.51 inch

- Face milling capacity: 30mm /1.18 inch

- End milling capacity: 16mm/0.63 inch

- Longitudinal travel: 100mm/3.94 inch

- Cross travel: 250mm /9.84 inch

- Spindle stroke: 200mm /7.87 inch

- Working table size: 460X 112mm/18.11 x4.41 inch

- Max distance spindle to table: 220mm /8.66 inch

- Spindle taper: MT3

- T-slot: 10mm /0.39 inch

- Spindle speed: 20 – 2500rpm

- Spindle rotary angle: -45 ~+45 degrees

- Dimension: 368X673X685mm /14.5x 26.5×27 inch

- X-Axis Travel Bed: 300mm/11.81 inch

- Y-Axis Travel Bed: 140mm/5.51 inch

- Z-Axis Travel Bed: 220mm/8.66 inch

- Table Size: 460*110mm/18.11×4.33 inch

- Weight: 80kg/176lbs

Comments Off