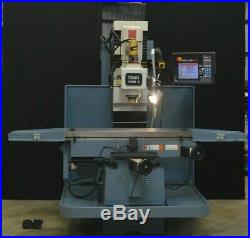

THIS LISTING COMES WITH A STAND. IF YOU WOULD LIKE A MACHINE WITHOUT THE STAND, PLEASE SEE OUR OTHER LISTING. Variable Speed Head, with all Hardened and Ground Steel Gears for. This machine uses 120V Standard Power! Highlights Of This Machine. Variable Spindle Speeds to perfectly match the speed to the job. Wide speed range, 40-3000 RPM. All Hardened and Ground Steel Gears in head, for much heavier. Cutting capability, particularly when compared with plastic gear equipped models. Compact Size for smaller work shops, but has more weight and power to. Remove material when needed. 001 on X and Y with a true Inch Pitch. Leadscrew, leads to easier operation when tolerances matter. Main Column is attached to the base with 4 bolts from the top, with. A very wide mounting surface for much more rigidity over other. Models in this size range. Only Requires Standard 120V Single Phase Circuit, so it can be. Set up virtually anywhere, without needing additional circuits. Installed in your work shop. Compact, Accurate, Economical Machine. Great for those who are looking for a compact machine for a smaller work shop, yet need the ability to take heavier cuts compared with other machines in this size range Spindle is Supported by High Precision Tapered Roller Bearings Mill Head May be Tilted ±90° (both left and right) Precision Manual Fine Down Feed is standard Adjustable Tapered Gibs for longer life Positive Locks are standard for Table, Head, Quill, and Column Easy Reading Dials Have Satin Chrome Finish, Graduated in. 001 Quill DRO is Standard, Accuracy of the Display 0.0005, Selectable from mm/inch Generous 18-1/4 Spindle To Table Max Distance for taller work 8-1/2 Y Axis Travel, More than other machines in this class. 3-Axis Digital Readout Installed. Average time delivered is 2-7 days depending on how far from Pittsburgh you are, it could be a little longer in remote places but normally is very fast. 1060 Montour West Industrial Park. We are machinists here too, so we know what we sell. This is really a top quality machine, and will last a long, long time. AND we are here for support too. We sell these machines regularly, we know them inside and out, and have been in business for many years, so if there is any question, we can help. End Milling Capacity: 1. Face Milling Capacity: 3. Table Size: 27-1/2 x 7-1/8. Cross Travel (Y Axis): 8-1/2. Longitudinal Travel (X Axis): 15. Table Leadscrew Pitch 10 TPI. Vertical Travel (Z Axis): 16. Max Distance Spindle to Table: 18-1/4. Taper of Spindle: R-8, w/7/16-20 Drawbar Thread. Spindle (Quill) Travel: 3. T Slot Size: 1/2T Slots are slightly less than 1/2, actual size 12mm, our 1/2 kit. Is sized for this machine. Range of Spindle Speeds: 40-3000 RPM, 6 STEPS and Variable. Head Tilt: Left & Right ±90°. Net Weight: 575 LBS. Power Required: 110/120V, 20 Amp Circuit. Dimensions: 39W x 70H x 30D. NO extra charge for residential or anything on these, as long as a truck can get to you, its covered. If you have ANY questions, feel free to message us. Check out our other auctions for more lathes and mills. The item “PM-727V VERTICAL BENCH TOP MILLING MACHINE WithSTAND DIGITAL READOUT FREE SHIPPING” is in sale since Thursday, November 14, 2019. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “qualitymachinetools” and is located in Pittsburgh, Pennsylvania. This item can be shipped to United States, Canada.

- Country//Region of Manufacture: China

- Non-Domestic Product: No

- Modified Item: No

- Custom Bundle: No

- MPN: PM-727V w/DRO AND PM-727V STAND

- Brand: Precision Matthews