2021

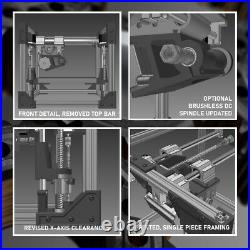

Ghost Gunner FLEX V2.2′Build Kit’ DIY & Open Source CNC Machining Center

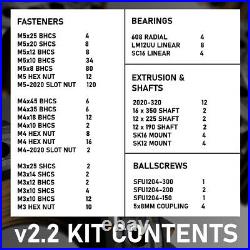

Customer service and technical requests/questions may also experience delayed or extended response times. The FLEX team has begun working with several established commercial suppliers to keep up with orders, but our manpower is still entirely made up of volunteers working in Open Source Tech spaces and we’re doing our best to help out everyone we can in a timely fashion! This listing is for a DIY’Builder Kit’ for the Ghost Gunner FLEX. These’Builder Kits’ contain the framing, fasteners, and linear motion components required to build the FLEX. In order to build a complete, functional CNC machine from this kit, users need to add/source the following items. Printed Parts (link) – We offer high quality, community-sourced printed parts as they come available, but also highly encourage users to print their own parts to get the most out of the project! A Mechatronics/Controls Suite (link) – Consisting of the stepper motors, their drivers, and a controller (with optional USB/SD slot and/or LCD screen) we have several supported choices to choose from. The Toolhead (link) – Since modularity is a huge focus for the FLEX project, it’s no surprise that we have several different supported options available. The standard choices are either trim router spindles or a brushless DC motor and spindle, but there are also 3D printing heads, grinding heads, laser engravers, and other options available and in various stages of development for the machine. Additionally when planning their build (or further down the road, with a completed machine) users may wish to check out the Optional Parts & Upgrades (link) that we have available for the FLEX. NOTE REGARDING VERSION UPDATES: The FLEX project is currently being expanded to take advantage of an advanced 32-bit controls suite and firmware. Doing so will provide space to integrate advanced toolhead options, the 4th and 5th axes, and a variety of more advanced reliability and functionaliy features. This 32-bit suite is not’plug-and-play’ with the original factory DDCut software and projects, so users who want the most streamlined setup possible (and don’t mind the’legacy’ controller suite/power) should source parts from our specific list of DDCut Compatible Hardware. The’legacy’ controls suite will not be supported in future’advanced features’ development. This Build Kit itself remains relatively unchanged between the v. 2.0/2.1 and newer v2.2 and can be used interchangeably with only a couple fasteners and two ballscrews needing to be swapped. The FLEX is a fully open source fork of the Ghost Gunner project by Defense Distributed which seeks to use more affordable and readily available materials commonly used in the open source tech space (3D printed parts, T-slot aluminum extrusion, and standard linear motion components). The launch iteration of the FLEX retains functional interchangeability of electronics and linear motion components with production Ghost Gunner 1 and 2 models, while future iterations will provide alternative construction methods and a wide variety of new features. If so, the option will be presented at Checkout. The item “Ghost Gunner FLEX V2.2′Build Kit’ DIY & Open Source CNC Machining Center” is in sale since Wednesday, May 12, 2021. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Metalworking Equipment\Machining Centers & Milling Machines”. The seller is “eem-llc” and is located in Fairfax, Virginia. This item can be shipped to United States.

- Model: V2.2

- Country/Region of Manufacture: United States

- Machine Type: Desktop Machining Center

- Table Length: 235mm

- X-Axis Travel Bed: 115mm

- Y-Axis Travel Bed: 200mm

- Z-Axis Travel Bed: 60mm

- Function: Grinding

- Brand: EEM-LLC

- Table Width: 60mm

- Control: CNC

Comments Off