2024

Moon Side Milling Cutter 3 x 3/4 x 1 Arbor HSS TiN Straight 32T

Number of Teeth: 32. Tooth Angle: 45 deg.

Comments Off

Number of Teeth: 32. Tooth Angle: 45 deg.

Comments Off

10 X 53 TABLE. POWERFEED ON THE HEAD. NICE, CLEAN RUNNING MACHINE. PRICE TO LOAD ON TRUCK…..

Comments Off

MiniMill CNC Mechanical Kit This is the Bulk-Man 3D kit of the popular Open Source MiniMill CNC Machine. The MiniMill was originally designed and published on Openbuilds. It is a super strong, accurate and easy to assemble CNC machine. Based on C-Beam, V-Slot, Xtreme Solid V-Wheels and TR8x8(P2) Leadscrews it is strong, accurate and reliable. It has been carefully designed and can accurately cut foams, woods, plastics and aluminium to 0.1-0.2mm accuracy or better. Functional engineering parts, toys, signs or anything else that can be imagined, can be made on the MiniMill Machine. MiniMill CNC Mechanical Kit. This is the Bulk-Man 3D kit of the popular Open Source MiniMill CNC Machine. No Motors, 3 x Nema23-1.26N. M Stepper Motors (Optional). All Extrusions are M5 Tapped as where it is necessary. Electronic parts as wire, Cable kits, Bosch Colt Router Spindle, Drive board, Power supply, working table etc and other. Electronic kits are NOT included with this kit. Compatible Material for Cutting/Milling/Engraving. Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam. Nema 23 Stepper Motors. Step angle: 1.8°±5%. Phase number: 2. Insulation resistane: 100M? Min. Insulation class: Class B. Rotor inertia: 280g. Mass: 0.72kg. Rated voltage: 3.36V. Rated current: 2.8A. Resistance per phase: 1.2? ±10%. Inductance per phase: 2.3mH±20%. Holding torque: 1.26N. Detent torque: 45mN. “V-Slot” and ” C-Beam” are registered trademarks of OpenBuilds LLC as released under the Creative Commons Licence Attribution-Share. All our components are designed to work and are fully compatible with the products produced by OpenBuilds. Terms of Sale (VAT). Return must include all original package and accesorries, item must in good condition. We will work with you to until you are satisfied. We will try our best to solve your problem to your satisfaction. We are always here with you! Our working time is 8 :30AM – 6:30PM from Monday – Friday.

Comments Off

X Axis Power Feed Table Milling Machine FOR Bridgeport Type Mill Power feed 220V. X Axis Power Feed Table Milling Machine Fit Bridgeport Type Mill Power feed 220V. Please provide the machine type picture before placing the order to judge whether the product meets your needs. The hole diameter of the gear is 16mm. The size of the center hole to the bottom is about 220mm. Set the fix stand on work table, set table bearing bushing on the axis screw, then set the power table feed on the fix stand, take out the gear housing. Use one hand to hold the center transmission shaft. Set the bevel gear on axis screw with the other hand. Then check if the backlash between gears is between 0.1-0.2mm. Add shims (1.0t, 0.25t, 0.1t) if the backlash is too large. Repeat step 2-3 until reaching satisfying backlash. Tighten the handle to start setting socket parallel key and bevel gear. Rotate the handle slightly to feel if any interfere occurs in between. If do, please repeat step 3-4 to add more shims. If not, go to next step. Take out the handle, add proper shim (? 43x? 33), adjust the backlash between dial & bevel gear and lock with fix ring. Set the handle and tighten, slightly rotate the handle. Normally it should be smooth without any interfere. Finally, set the gear housing and limit switch. Power supply switch and reset switch. The right side of power switch is “ON”. The left side is OFF. Red light will show when machine is on. The red round button on right side is reset switch. Reset button will jump up to cut off the power if the machine overloads. The operator must reduce cutting load, then press reset switch to continue operating. Feed knob and rapid button. Rotate feed knob after power is on. Turn left for left side feeding and vice versa. The button in the middle is “rapid button”. Tool will travel rapidly to left side if you keep pressing the button. Release to make power table feed will back to normal speed. Speed can be adjust according to operator’s requirement, ranging from 0-9. Normally, jog switch should be at “FEED” position. For jog movement, just switch to “0″ position. Kept holding the switch until it travels to requires position. NOTE: To stop jog operating, you must first turn “FEED KNOB” TO “0″(OFF) position. Then move “JOG SWITCH” to “FEED” position. Be sure to follow the procedure for jog operation to avoid any damage caused by wrong movement. Gear cover must be open every 6 month to check whether lubrication for spiral gear is sufficient. Graphite type lubrication is suggested rather than silicon type. Carbon brush cap should be open every 6 month to check if the brush has wore out. Brush should be replace immediately if its length is under 5mm (front and back brush should be replaced together). Add an auto power table feed to your milling machine! A simple and inexpensive way to increase productivity! Small volume and easy installation. Excellent speed control in the entire range. Jog function operates at any feed speed. Power table feed won’t vibrate or strain in low speed. Direction control knob for easy and rapid operation. Safety feature to protect transmission gear and electronic components. 1 x APF-260 Power Feed. 1 x X-Axis Fix Stand with Bushing. 1 x Bevel Gear with Fix Ring. 1 x Handle Washer. 2 x Stop Blocks. 2 x Stop Set. 2 x Socket Screws (M8P1.2535). 2 x Socket Screws (M8P1.025). 6 x Small Shims (? 26.2? 16.20.25t). 2 x Small Shims (? 26.2? 16.20.1t). 3 x Small Shims (? 26.2? 16.21.0t). 4 x Large Shims (? 43.4? 33.40.25t). 2 x Spring Pins. 1 x Cable Clamp. 1 x User Manual. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Stable performance and high quality?

Comments Off

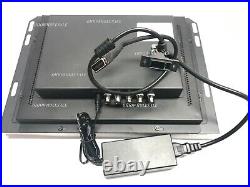

Direct fit, no need to drill and tap holes for mounting the LCD monitor. The package includes following items. 1 piece of 14 inch industrial LCD screen with mounting bracket. 1 piece of video signal adapter cable. Power supply with power cord. It is time to replace your old CRT monitors with the new high quality LCD industrial monitors. If the monitor you need is not in my store, just ASK! UPS overnight service is available, choose UPS overnight when you check out. Thank you for supporting American small business!

Comments Off

The pre-cut mounting slots ensure that the installation WILL be easy and straight forward. The package includes following items. 1 piece of 14 inch industrial LCD screen with mounting bracket. 1 piece of video signal adapter cable. Power supply with power cord. It is time to replace your old CRT monitors with the new high quality LCD industrial monitors. If the monitor you need is not in my store, just ASK! Thank you for supporting American small business!

Comments Off

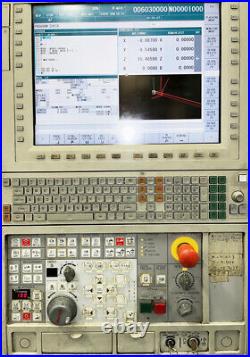

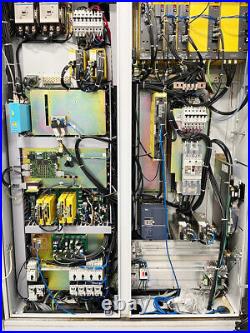

USED 2010 MORI NH4000 DCG 21-Pallet (RPP) Vertical Pallet Stocker System with MSX-501IIIIMB MAPPS I Control in excellent condition. Control: MORI SEIKI MSX-501IIIIMB MAPPS I. Tool Storage Capacity: 360 – Matrix Type ATC. NC System: FS-31IA (MAPPS 4). Pallet Changer: 21 RPP – Vertical Pallet Stocker Cell. Customer Factory Voltage (V): 220 V. Spindle 20,000 RPM. Spindle Hole Taper (CAT #40): 7/24 Taper (Two-Face Contact) #40. Retention Knob Standard (#40): 90 Degree. Rapid Traverse Rate (M/Min): 50 M/Min. Linear APC Setup Station Arrangement: On Machine. Control System: Interface Only. Steps of Pallet Stand: 2 Steps Style. Number of Machines For Linear APC: 1 Machine. Number of Setup Stations For Linear APC: 1 Setup Station. Pallet Size: 400 Square. Full 4th Axis Rotary Table. Chip Disposal Direction: Rear Disposal Type. Chip Conveyor Outside Machine: Provided. Type of Chip Conveyor Outside Machine: Scraper (Drum Filter Type). Through-Spindle Coolant System: Side Through. Through-Spindle Coolant System (Unit): Interface Only. Through-Spindle Coolant System Interface Type: Ogura Clutch/Shinano Kikou I/F. Shower Coolant Discharge Pressure: Standard. In-Machine Work Measuring System (Spindle): Optical Type Probe Sensor (Renishaw). In-Machine Work Measuring System (Table): Table Mount Sensor (Renishaw). Part Program Strage (Byte): 512 Kbyte (1280 M). Remote Communication Function: Fast Data Server (100Base-TX). User Memory Area(Built-In MAPPS): 1 GB. Number of Tool Offset Pairs: 400. Number of Work Coordinate System Pairs: 300. Number of Custom Macro Common Variables: 600. Tool Life Management: Provided. Additional Number of Tool Life Management: Provided (Max: 1024 Pairs).

Comments Off