2024

Mori Seiki 2010 NH4000 DCG 21-Pallet (RPP) Vertical Pallet Stocker System

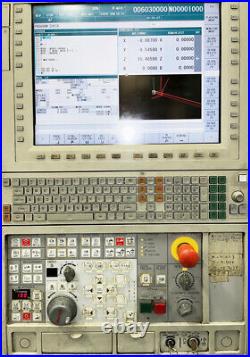

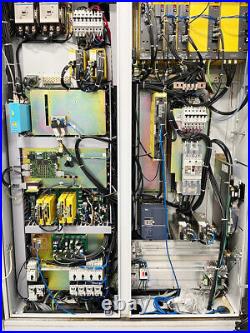

USED 2010 MORI NH4000 DCG 21-Pallet (RPP) Vertical Pallet Stocker System with MSX-501IIIIMB MAPPS I Control in excellent condition. Control: MORI SEIKI MSX-501IIIIMB MAPPS I. Tool Storage Capacity: 360 – Matrix Type ATC. NC System: FS-31IA (MAPPS 4). Pallet Changer: 21 RPP – Vertical Pallet Stocker Cell. Customer Factory Voltage (V): 220 V. Spindle 20,000 RPM. Spindle Hole Taper (CAT #40): 7/24 Taper (Two-Face Contact) #40. Retention Knob Standard (#40): 90 Degree. Rapid Traverse Rate (M/Min): 50 M/Min. Linear APC Setup Station Arrangement: On Machine. Control System: Interface Only. Steps of Pallet Stand: 2 Steps Style. Number of Machines For Linear APC: 1 Machine. Number of Setup Stations For Linear APC: 1 Setup Station. Pallet Size: 400 Square. Full 4th Axis Rotary Table. Chip Disposal Direction: Rear Disposal Type. Chip Conveyor Outside Machine: Provided. Type of Chip Conveyor Outside Machine: Scraper (Drum Filter Type). Through-Spindle Coolant System: Side Through. Through-Spindle Coolant System (Unit): Interface Only. Through-Spindle Coolant System Interface Type: Ogura Clutch/Shinano Kikou I/F. Shower Coolant Discharge Pressure: Standard. In-Machine Work Measuring System (Spindle): Optical Type Probe Sensor (Renishaw). In-Machine Work Measuring System (Table): Table Mount Sensor (Renishaw). Part Program Strage (Byte): 512 Kbyte (1280 M). Remote Communication Function: Fast Data Server (100Base-TX). User Memory Area(Built-In MAPPS): 1 GB. Number of Tool Offset Pairs: 400. Number of Work Coordinate System Pairs: 300. Number of Custom Macro Common Variables: 600. Tool Life Management: Provided. Additional Number of Tool Life Management: Provided (Max: 1024 Pairs).

Comments Off