2024

1SET CNC Milling Machine Part R8 Spindle +Bearings Assembly For BRIDGEPORT Tool

Name: Milling R8 spindle+. Suitable for most milling machines.

Comments Off

Name: Milling R8 spindle+. Suitable for most milling machines.

Comments Off

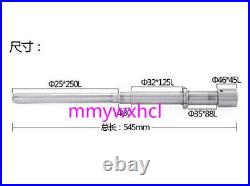

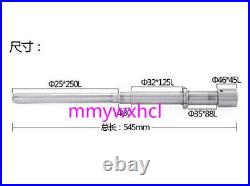

Mill Machine Parts R8 Spindle + Bearings Assembly Fit BRIDGEPORT Milling US Product description: This product is a high quality R8 spindle + bearing for 3#4# milling machine. After the spindle is replaced, it can change the surface or side of the milling workpiece caused by the tool wear caused by the long wear of the spindle and the bearing clearance. Smooth, rough and uneven! Product specifications: Name: Milling R8 spindle + bearing Total length of the spindle: 545mm Head outer diameter: 46mm Spline outer diameter: 25mm D:25mm D1:20mm B:6mm Bearing position: 35mm and 30mm Packing size: 561010cm Weight: 4.2kg Scope of application: Most milling machines (3#4# milling machine) The package includes: 1X R8 spindle + bearing. Manual Mill Machine Parts R8 Spindle Bearings Assembly For Bridgeport Milling. Mill Machine Parts R8 Spindle + Bearings Assembly Fit Bridgeport Milling Usa. This Product Is a High Quality R8 Spindle + Bearing for 3#4# Milling Machine. After the Spindle Is Replaced, It Can Change the Surface or Side of the Milling Workpiece Caused by the Tool Wear Caused by the Long Wear of the Spindle and the Bearing Clearance. Smooth, Rough and Uneven! Name: Milling R8 Spindle + Bearing. Total Length of the Spindle: 545mm. Head Outer Diameter: 46mm. Spline Outer Diameter: 25mm. Bearing Position: 35mm and 30mm. Scope of Application: Most Milling Machines (3#4# Milling Machine). 1x R8 Spindle + Bearing. Dear friend, Welcome to my store. Wish you have a nice day and happy shopping. If you have any questions or more information about promotion, please leave me a message and we will reply to you as soon as possible. Thanks for your patience. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Unique Appearance, Great Durability. Compact Design, Convenient Use. Easy installation, Compact Design. Stable performance, Safe to Use. Milling R8 spindle + bearing. Total length of the spindle. Most milling machines (3#4# milling machine).

Comments Off

Mill Machine Parts R8 Spindle + Bearings Assembly Fit Milling US Product description: This product is a high quality R8 spindle + bearing for 3#4# milling machine. After the spindle is replaced, it can change the surface or side of the milling workpiece caused by the tool wear caused by the long wear of the spindle and the bearing clearance. Smooth, rough and uneven! Product specifications: Name: Milling R8 spindle + bearing Total length of the spindle: 545mm Head outer diameter: 46mm Spline outer diameter: 25mm D:25mm D1:20mm B:6mm Bearing position: 35mm and 30mm Packing size: 561010cm Weight: 4.2kg Scope of application: Most milling machines (3#4# milling machine) The package includes: 1X R8 spindle + bearing. 1 Set Bridgeport Milling Machine Parts R8 Spindle + Bearings Assembly Kit. Mill Machine Parts R8 Spindle + Bearings Assembly Fit Milling Usa. This Product Is a High Quality R8 Spindle + Bearing for 3#4# Milling Machine. After the Spindle Is Replaced, It Can Change the Surface or Side of the Milling Workpiece Caused by the Tool Wear Caused by the Long Wear of the Spindle and the Bearing Clearance. Smooth, Rough and Uneven! Name: Milling R8 Spindle + Bearing. Total Length of the Spindle: 545mm. Head Outer Diameter: 46mm. Spline Outer Diameter: 25mm. Bearing Position: 35mm and 30mm. Scope of Application: Most Milling Machines (3#4# Milling Machine). 1x R8 Spindle + Bear. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Milling R8 spindle + bearing. Total length of the spindle. Most milling machines (3#4# milling machine).

Comments Off

You may also like. 1Pcs New For LAPPING linear guide slider LSA30R. 1PCS New HGW45CC Flange Block Linear Guideway Block. 5PCS/Lot New MGW9H Linear Guideway Block. 1Pcs New For CSK Linear Guide Slider LMG25H. 10PCS/Box New WDXT186012-G CNC Blade ACP300. 10PCS/Box New CNGA120412 CNC Blade A66N. We are professional industrial parts supplier of accessories and replacement parts. In the Greater China Area. We apply comprehensive quality check and testing before dispatching. This item could be used to r. Which is broken, damaged, cracked or unusable. Asia and Other Countries. We appreciate your comprehension that there might be delay during the national holidays and traditional festivals.

Comments Off

Mill Machine Parts R8 Spindle + Bearings Assembly Fit BRIDGEPORT Milling US Product description: This product is a high quality R8 spindle + bearing for 3#4# milling machine. After the spindle is replaced, it can change the surface or side of the milling workpiece caused by the tool wear caused by the long wear of the spindle and the bearing clearance. Smooth, rough and uneven! Product specifications: Name: Milling R8 spindle + bearing Total length of the spindle: 545mm Head outer diameter: 46mm Spline outer diameter: 25mm D:25mm D1:20mm B:6mm Bearing position: 35mm and 30mm Packing size: 561010cm Weight: 4.2kg Scope of application: Most milling machines (3#4# milling machine) The package includes: 1X R8 spindle + bearing. NEW 1 SET BRIDGEPORT Milling Machine Parts R8 Spindle + Bearings Assembly Kit. Mill Machine Parts R8 Spindle + Bearings Assembly Fit Bridgeport Milling Usa. This Product Is a High Quality R8 Spindle + Bearing for 3#4# Milling Machine. After the Spindle Is Replaced, It Can Change the Surface or Side of the Milling Workpiece Caused by the Tool Wear Caused by the Long Wear of the Spindle and the Bearing Clearance. Smooth, Rough and Uneven! Name: Milling R8 Spindle + Bearing. Total Length of the Spindle: 545mm. Head Outer Diameter: 46mm. Spline Outer Diameter: 25mm. Bearing Position: 35mm and 30mm. Scope of Application: Most Milling Machines (3#4# Milling Machine). 1x R8 Spindle + Bearing. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. Creative Design, Durable Material, Beautiful Appearance. Stable characteristic, High reliability. Easy installation, Compact Design. Stable performance, Safe to Use. Milling R8 spindle + bearing. Total length of the spindle. Most milling machines (3#4# milling machine).

Comments Off

High Precision 1um 2/3 Axis Digital Readout Linear Glass Scale TTL DRO Display for Milling Lathe Application : This kind of DRO is commonly fitted to machines, especially for metal working – lathes, cylindrical grinders, milling machines, surface grinders, boring mills and other machine tools – to allow the operator to work faster and with greater accuracy Supply Voltage range : AC 80V260V; 5060Hz, US Plug Power consumption: 15VA Operating temperature: 045 degree centigrade Storage temperature: -3070 degree centigrade Relative humidity: Less than 90% Readout allowable input signal: TTL square wave Allowable input signal frequebcy: Less than 5MHz Max resolution of digital display length: 1µm (0.001mm/0.0001) Min resolution of digital display angle :0.0001/pulse. 1? M (0.0001) High Precision DRO DRO must be set to completely match the linear scale accuracy. Circumference holes processing, linear holes processing, ARC processing. Oblique processing, slope processing. Chamber processing, R function, the tool diameter compensation function, digital. Pin 1 to 4 connects +5V, 0V, A, B. Pin 5-9 is blank. DOUBLE SEAL & SIGNAL ABLE. Signal cable uses multilayer shielded wire steel and metal shell to provide extra protection. Deafult offer 3meters (9.84feet long) cable connecting with linear scale. Sensor adopts the precision metrology grating as the measurement standard. And the sliding parts have excellent repeatable positioning performance. Full set of installation accessories (L type cover, backplate and screws) included inside the linear scale, each scale equipped with some extra screws to avoid unsccessful installation. Applications: Milling Machine, Lathe, EDM, Grinder etc. Relative humidity: Less than 90%. Readout input signal: TTL square wave. Input signal frequency: Less than 5M Hz. 1µm (0.001mm/0.0001). Min resolution of DRO angle :0.0001/pulse. DRO Dimensions: 11.6″X6.7″X2.56. Linear Scale Interface: DB9(RS232). SDM 200 sets memory, power-off memory for 10years, circumference drilling, oblique line drilling, 1/2 centering. The simple R function. Chambering (applicable to: Milling machine, Boring machine). Tool conpensation (for lathe). Machining of oblique plane. 1pc DRO Or 1pc Linear Scale 1um (100/150/200/250…2000MM) 1Set Installation Accessories. 2AXIS DRO LCD SCREEN. 3AXIS DRO LCD SCREEN. FAQ: Q1 : are the length 100, 150, 200…. Answer : all are travel length Q2: if i need 250mm , 1000mm scales with 2axis digital readout, how should i do? Answer : Please contact ToAuto Team to get the video. (press 6 times after DRO powers on). Q5 : Can i cut the scales by myself? Answer : Technically NO, it maybe unavailable after cutting. Q6: How can i change the 5? M to 1? M display? Q7: Is it easy to install these scales and DRO? Please contact ToAuto to get the video. Answer : Please must check the scale pin definition (1,2,3,4,5,6,7,8,9), which is very important!!!

Comments Off

Dovetail Cutter, 1-1/4, Carbide Tipped. Dovetail Cutter, 60 Degrees Included Angle, 1/2 in Cutter Thickness, Carbide Tipped. Carbide-tipped dovetail milling cutters have carbide cutting edges that provide excellent hardness and heat resistance and retain their hardness better than high-speed steel or cobalt steel cutting edges. The body of the milling cutter is made from a material that can tolerate more vibration and shock than carbide. The cutters have a flat on their shank for securing them to a milling machine with a set screw. Dovetail milling cutters have a tapered cutting head that is wider at the tip of the cutting head than at the point where the cutting head meets the shaft. They are designed to create dovetail slots, or tapered grooves, in a workpiece. Parts can be slid or pressed into the dovetail slot to join them to the workpiece, and the tapered shape of the dovetail slot prevents the mated part from becoming dislodged. Dovetail milling cutters are used in manufacturing and production facilities. Grainger Part #:33UX35. Add to Favorite Sellers. Sign up to Newsletter. View more great items. DAYTON 1LPW2 DC Gearmotor, 21 rpm, 90V, TENV. GRAINGER APPROVED 6GLC5 Glove Drying Rack, Steel, Black. NITE IZE NPXL-03-01 Clip Pock-its XL Utility Holster, Nylon. CARLING TECHNOLOGIES CMB-053-27G3N-W-A/05 Circuit Breaker, 5A, Thermal, 125/250VAC. These items are intended to be used in North America. Power adapters and other modifications may be necessary for proper operation in other countries. GRAINGER STANDARD TERMS AND CONDITIONS. Please read these terms and conditions carefully. They contain important information concerning customer? Legal rights, warranties, obligations and available dispute resolutions remedies. They also provide that if Grainger is unable to resolve any matter to Customer? S satisfaction, Customer will exclusively use arbitration to decide the dispute and Customer will bring its claim solely on an individual basis and not in a class action or representative proceeding. Grainger reserves the right to revise these Terms and Conditions at any time. Product Compliance and Suitability. Jurisdictions have varying laws, codes and regulations governing construction, installation, and/or use of products for a particular purpose. Certain products may not be available for sale in all areas. Grainger does not guarantee compliance or suitability of the products it sells with any laws, codes or regulations, nor does Grainger accept responsibility for construction, installation and/or use of a product. It is Customer’s responsibility to review the product application and all applicable laws, codes and regulations for each relevant jurisdiction to be sure that the construction, installation, and/or use involving the products are compliant. S acceptance of any order is subject to Customer? S assent to all of the terms and conditions set forth herein. Customer’s assent to these terms and conditions shall be presumed from Customer’s receipt of Grainger? S acknowledgment, or from Customer? S acceptance of all or any part of the products ordered. No additions or modifications of Grainger? S terms and conditions by Customer shall be binding upon Grainger, unless agreed to in writing by an authorized representative of Grainger. Grainger reserves the right to accept or reject any order. The terms and conditions in: (i) Grainger? S forms; (ii) acknowledgments; (iii) quotations; (iv) invoices; (v) web sites; (vi) catalogs; and (vii) extension of credit are incorporated herein by reference, and constitute the entire and exclusive agreement between Customer and Grainger. Business Customers hereby agree to indemnify and hold Grainger harmless against any breach of this representation. ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS. IN ADDITION TO THE STANDARD TERMS AND CONDITIONS IN SECTION I, EXPORT SALES OF GRAINGER PRODUCTS WILL BE GOVERNED BY THE FOLLOWING ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS? IN THE EVENT OF A CONFLICT BETWEEN GRAINGER? S STANDARD TERMS AND CONDITIONS IN SECTION I AND THE ADDITIONAL EXPORT TERMS IN SECTION III, THE ADDITIONAL TERMS IN SECTION III SHALL PREVAIL FOR EXPORT SALES OF GRAINGER PRODUCTS. Customer acknowledges that no order shall be deemed accepted unless and until it is verified and accepted by Grainger, or any of its U. Affiliates and divisions, at a continental U. Facility or at any of its websites. Customer further consents that submission of its order shall subject Customer to the jurisdiction of the federal courts of the U. And of the State where acceptance occurred in the U. Grainger is required to charge U. Export Controls and Related Regulations. Customer represents and warrants that it is not designated on, or associated with, any party designated on any of the U. Government restricted parties lists, including without limitation, the U. Commerce Department Bureau of Industry and Security? Denied Persons List; Entity List or Unverified List; the U. Treasury Department Office of Foreign Assets Control? Specially Designated Nationals and Blocked Persons List; or the U. State Department Directorate of Defense Trade Controls? Customer shall comply with all applicable U. Economic sanctions and export control laws and regulations, including without limitation, the regulations administered by OFAC, the Export Administration Regulations? Administered by BIS, and the International Traffic in Arms Regulations administered by DDTC. It is specifically agreed that Customer shall be the foreign principal party in interest? In the event a license is required for export from the U. Agent of the FPPI the exporter of record for purposes of meeting EAR requirements. Country of Importation and Anti-diversion. Customer represents that it is purchasing products from the U. And importing them to the country for the use of the ultimate consignee specified in the Customer and Grainger documentation. Customer agrees that the products will not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U. Government or as otherwise authorized by U. Any commodities, technology and software will be exported from the U. In accordance with the U. Export Administration Regulations and other applicable laws or regulations. Diversion contrary to U. Customer further agrees to inform Grainger at the time of order of any North American Free Trade Agreement or other special documentation, packaging or product marking or labeling, but Grainger shall not be responsible for providing any such documentation, packaging, marking or labeling other than such documents that are necessary under U. Export laws and regulations for export, unless Grainger expressly agrees to do so. Permits, Export, and Import Licenses. Customer shall be responsible for obtaining any licenses or other official authorizations that may be required by the country of importation. When the Customer is designated as the U. Principal Party of Interest, the Customer shall be responsible for obtaining licenses under the EAR, International Traffic in Arms Regulations, Toxic Substances Control Act, or other applicable laws or regulations. If the Customer is the FPPI, then the terms contained in subsection 6 of this Section III shall apply. The rights and obligations of the parties under these terms and conditions shall not be governed by the provisions of the 1980 United Nations Convention of Contracts for the International Sale of Goods or the United Nations Convention on the Limitation Period in the International Sale of Goods. Rather, these terms and conditions shall be governed by the laws of the State of Illinois, U. Including its provisions of the Uniform Commercial Code, but excluding its conflict of law rules.

Comments Off

Dovetail Cutter, 1/2, Carbide Tipped. Dovetail Cutter, 45 Degrees Included Angle, 7/32 in Cutter Thickness, Carbide Tipped. Carbide-tipped dovetail milling cutters have carbide cutting edges that provide excellent hardness and heat resistance and retain their hardness better than high-speed steel or cobalt steel cutting edges. The body of the milling cutter is made from a material that can tolerate more vibration and shock than carbide. The cutters have a flat on their shank for securing them to a milling machine with a set screw. Dovetail milling cutters have a tapered cutting head that is wider at the tip of the cutting head than at the point where the cutting head meets the shaft. They are designed to create dovetail slots, or tapered grooves, in a workpiece. Parts can be slid or pressed into the dovetail slot to join them to the workpiece, and the tapered shape of the dovetail slot prevents the mated part from becoming dislodged. Dovetail milling cutters are used in manufacturing and production facilities. Grainger Part #:33UX29. Add to Favorite Sellers. Sign up to Newsletter. View more great items. DAYTON 1LPW2 DC Gearmotor, 21 rpm, 90V, TENV. GRAINGER APPROVED 6GLC5 Glove Drying Rack, Steel, Black. NITE IZE NPXL-03-01 Clip Pock-its XL Utility Holster, Nylon. CARLING TECHNOLOGIES CMB-053-27G3N-W-A/05 Circuit Breaker, 5A, Thermal, 125/250VAC. These items are intended to be used in North America. Power adapters and other modifications may be necessary for proper operation in other countries. GRAINGER STANDARD TERMS AND CONDITIONS. Please read these terms and conditions carefully. They contain important information concerning customer? Legal rights, warranties, obligations and available dispute resolutions remedies. They also provide that if Grainger is unable to resolve any matter to Customer? S satisfaction, Customer will exclusively use arbitration to decide the dispute and Customer will bring its claim solely on an individual basis and not in a class action or representative proceeding. Grainger reserves the right to revise these Terms and Conditions at any time. Product Compliance and Suitability. Jurisdictions have varying laws, codes and regulations governing construction, installation, and/or use of products for a particular purpose. Certain products may not be available for sale in all areas. Grainger does not guarantee compliance or suitability of the products it sells with any laws, codes or regulations, nor does Grainger accept responsibility for construction, installation and/or use of a product. It is Customer’s responsibility to review the product application and all applicable laws, codes and regulations for each relevant jurisdiction to be sure that the construction, installation, and/or use involving the products are compliant. S acceptance of any order is subject to Customer? S assent to all of the terms and conditions set forth herein. Customer’s assent to these terms and conditions shall be presumed from Customer’s receipt of Grainger? S acknowledgment, or from Customer? S acceptance of all or any part of the products ordered. No additions or modifications of Grainger? S terms and conditions by Customer shall be binding upon Grainger, unless agreed to in writing by an authorized representative of Grainger. Grainger reserves the right to accept or reject any order. The terms and conditions in: (i) Grainger? S forms; (ii) acknowledgments; (iii) quotations; (iv) invoices; (v) web sites; (vi) catalogs; and (vii) extension of credit are incorporated herein by reference, and constitute the entire and exclusive agreement between Customer and Grainger. Business Customers hereby agree to indemnify and hold Grainger harmless against any breach of this representation. ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS. IN ADDITION TO THE STANDARD TERMS AND CONDITIONS IN SECTION I, EXPORT SALES OF GRAINGER PRODUCTS WILL BE GOVERNED BY THE FOLLOWING ADDITIONAL TERMS AND CONDITIONS RELATED TO EXPORT OF GRAINGER PRODUCTS? IN THE EVENT OF A CONFLICT BETWEEN GRAINGER? S STANDARD TERMS AND CONDITIONS IN SECTION I AND THE ADDITIONAL EXPORT TERMS IN SECTION III, THE ADDITIONAL TERMS IN SECTION III SHALL PREVAIL FOR EXPORT SALES OF GRAINGER PRODUCTS. Customer acknowledges that no order shall be deemed accepted unless and until it is verified and accepted by Grainger, or any of its U. Affiliates and divisions, at a continental U. Facility or at any of its websites. Customer further consents that submission of its order shall subject Customer to the jurisdiction of the federal courts of the U. And of the State where acceptance occurred in the U. Grainger is required to charge U. Export Controls and Related Regulations. Customer represents and warrants that it is not designated on, or associated with, any party designated on any of the U. Government restricted parties lists, including without limitation, the U. Commerce Department Bureau of Industry and Security? Denied Persons List; Entity List or Unverified List; the U. Treasury Department Office of Foreign Assets Control? Specially Designated Nationals and Blocked Persons List; or the U. State Department Directorate of Defense Trade Controls? Customer shall comply with all applicable U. Economic sanctions and export control laws and regulations, including without limitation, the regulations administered by OFAC, the Export Administration Regulations? Administered by BIS, and the International Traffic in Arms Regulations administered by DDTC. It is specifically agreed that Customer shall be the foreign principal party in interest? In the event a license is required for export from the U. Agent of the FPPI the exporter of record for purposes of meeting EAR requirements. Country of Importation and Anti-diversion. Customer represents that it is purchasing products from the U. And importing them to the country for the use of the ultimate consignee specified in the Customer and Grainger documentation. Customer agrees that the products will not be resold, transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in their original form or after being incorporated into other items, without first obtaining approval from the U. Government or as otherwise authorized by U. Any commodities, technology and software will be exported from the U. In accordance with the U. Export Administration Regulations and other applicable laws or regulations. Diversion contrary to U. Customer further agrees to inform Grainger at the time of order of any North American Free Trade Agreement or other special documentation, packaging or product marking or labeling, but Grainger shall not be responsible for providing any such documentation, packaging, marking or labeling other than such documents that are necessary under U. Export laws and regulations for export, unless Grainger expressly agrees to do so. Permits, Export, and Import Licenses. Customer shall be responsible for obtaining any licenses or other official authorizations that may be required by the country of importation. When the Customer is designated as the U. Principal Party of Interest, the Customer shall be responsible for obtaining licenses under the EAR, International Traffic in Arms Regulations, Toxic Substances Control Act, or other applicable laws or regulations. If the Customer is the FPPI, then the terms contained in subsection 6 of this Section III shall apply. The rights and obligations of the parties under these terms and conditions shall not be governed by the provisions of the 1980 United Nations Convention of Contracts for the International Sale of Goods or the United Nations Convention on the Limitation Period in the International Sale of Goods. Rather, these terms and conditions shall be governed by the laws of the State of Illinois, U. Including its provisions of the Uniform Commercial Code, but excluding its conflict of law rules.

Comments Off

This is a high-quality C2 universal head suitable for most milling machines with J head milling machine RAM adapter M1187 milling machine parts. Material: high quality metal Model: M1187 Bottom diameter: 190mm Height: 225cm Detailed other dimensions are shown in the figure Packing size: 30.533.526CM Gross weight: 13KG Net weight: 11kg. M1187 Milling Machine Parts RAM Adapter Bridge Port Type J Head Milling Machine. Top Quality Bridge Port Type Mill Part, J Head Milling Machine Ram Adapter M1187. This Is a High-quality C2 Universal Head Suitable for Most Milling Machines with J Head Milling Machine Ram Adapter M1187 Milling Machine Parts. 1x M1187 J Head Milling Machine Ram Adapter. Material: High Quality Metal Model: M1187. Packing Size: 30.533.526cm. Detailed Other Dimensions Are Shown in the Figure. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. High quality & Duable. J Head Milling Machine RAM Adapter. Adjust the head angle.

Comments Off