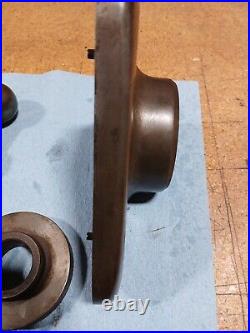

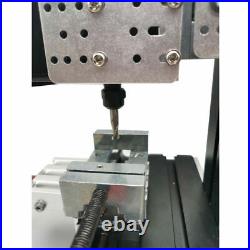

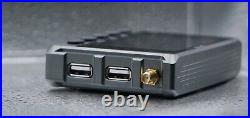

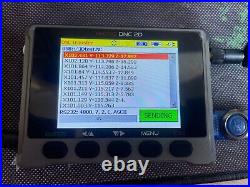

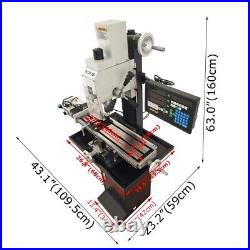

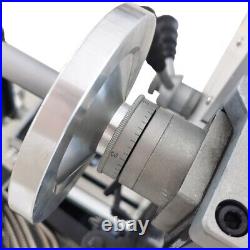

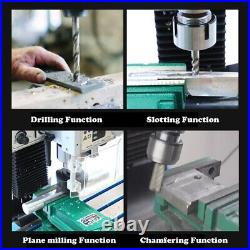

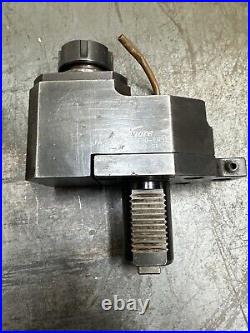

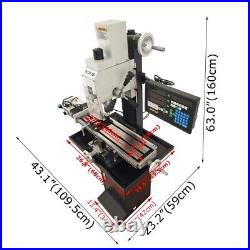

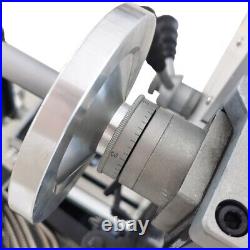

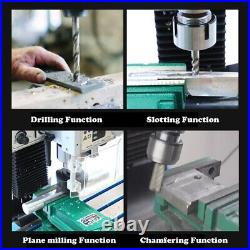

1300W RCOG-28V Brushless Precisi. 110V 1300W RCOG-28V Brushless Precision Milling and Drilling Machine (Including Axis X Power Feed and Three – axis Grating Ruler). RCOG-28V multi-functional drilling and milling machine has rich functions, can meet the metal, wood, plastic, Buddha beads and other finishing, all copper brushless motor, strong power, simple operation, durable, high processing accuracy, is the home DIY processing of various parts of the necessary machine. ±90°(The nose can actually rotate 360 degrees). Distance from spindle to table. The Range of spindle speeds. 27.5″7.1″(700mm180mm). 320.8LB(145.5kg)/386.9LB(175.5kg). Product Features & Advantages. Workbench is equipped with a bench clamp, the bench clamp is fixed on the workbench, can be used to clamp a variety of workpiece processing, clamping effect is good, save time and effort. Motor power up to 1300W!! Adopt high quality brushless motor, with overload and overheating protection function; Belt drive, high efficiency, low energy consumption, low noise; Long service life. The head of the machine can be tilted to the left and to the right by loosening the fixing screws of the head of the machine. The tilt Angle range is up to 90°, which is easy for drilling and milling special angles. The rotating speed display and the drilling and milling depth display are all high-definition LCD screens, which are clearer and richer than the previous digital tube display and convenient to operate. Spindle micro feed locking handle, convenient manual control of drilling and milling depth, release the hand can automatically return to the starting position. The processing table is designed behind the drainage hole, through the connection of the hose can be discharged at any time in the process of cooling liquid and excess oil. Axis X Power Feed. Equipped with axis X power feed, can achieve positive and reverse reversing and stepless speed regulation, running more stable, less noise; Greatly improve the machining accuracy and efficiency. Equipped with a three-axis digital display grating ruler, can realize the Angle or length measurement and control; The accuracy reaches 0.005mm, greatly improve work efficiency and machining accuracy. With one key start/stop protection switch and positive/negative switch, the spindle speed can be adjusted within the range of 20-2250rpm, easy to operate; Waterproof switch, safer. With drilling, plane milling, milling groove, chamfering and other functions, suitable for all kinds of metal, wood and other materials fine processing, widely used in all walks of life DIY. Powerful function: This is a multi-functional drilling and milling machine, can complete drilling and milling operations. Also can be used for precision parts processing, sample processing and model. Three axis grating ruler: Three axis grating ruler includes zero clear, preset, inch/metric display, relative/absolute switch, automatic sub-centers, calculator, power failure memory, RI and other functions, greatly improve the processing efficiency and accuracy! – All metal: It USES an integrated spindle and brass gear, which makes it not only precise but also durable. Variable-Speed: Weather you need high speed or lower speed spindle operations this machine can handle it. Boasting a 20-2250 RPM spindle speed for the extreme precision your project needs. It is important to note that this lathe has only a metric scale. Drilling and milling machine 1. Axis X power feed 1. Milling chuck set 1. Drill chuck retaining pin 1. Drill chuck wrench 1. You can make order with no worry. Any concern just feel free to let us know, we’ll reply in 24 hours in normal condition. Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method. Hope for your understanding. Please contact with us at first for more details. Defective & Damaged Products. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it’s much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. Payments via eCheck do not clear immediately. Usually you will wait 5-7 days after checkout for it to clear.