2025

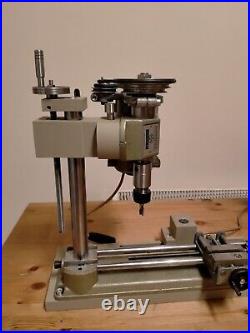

Pm-833t Ultra Precision Bench Top Vertical Milling Machine Free Ship! Taiwan

100% MADE IN TAIWAN. (No stand is included in this listing, if you would like a machine with the stand, please see our other listing). This machine uses 220V Power! Highlights Of This Machine. Very High Quality Milling Machine, 100% Made in Taiwan. Built For Those Users Who Are Looking For Higher Quality In A Dovetail Type Mill Configuration. Very Large Y and Z Travels Compared With Other Models In This Class, over 11? Of Y axis Travel. One Shot Lube System Standard. Very High Grade Castings Used Throughout Machine. Head Swivels 90 degrees Left and Right for angled milling / drilling operations. Hand Scraped way Surfaces for better oil retention and fit, which leads to ultra smooth. One Shot Lubrication system is standard equipment, which also extends machine life, and. High precision Inch Pitch lead screws, for ease of use and greater accuracy (10 TPI Screws). High Precision Spindle with +/. 0002 or less runout for greater tool life and accuracy. Balanced gears in head for smooth and quiet operation, Hardened and Precision Ground for long. Life, and extremely quiet running for a geared head machinE. Precision Honed Quill Bore for tighter tolerance fit, which leads to improved accuracy when. Drilling and precision boring. The Quill is Precision Ground, for higher accuracy. No belts to change, simply stop and move levers for speed changes, quick and easy. Tolerance Test check, each machine is checked for accuracy through a careful inspection. That exceeds their expectations. Question 2: Is there any other difference in the machines, besides what is described above? All accessories such as power feeds, stands, DRO, etc. Are the same between both models. Answer 3: It really depends what you are doing or think you will be doing. The 833T is still fine with cutting Aluminum and similar materials, no problem with that, you just have a lower spindle speed, so you may just have to go a little bit slower with feed rates, but it will still do the job just fine. So the 833T-V is a better choice if you are doing more higher speed aluminum cutting and want to get maximum feed rates, but it still has plenty of power at lower speeds for any type of general purpose work in steel, stainless steel, cast iron, etc. Just not quite as much power as the 833T at lower speeds. Either machine can do any materials that you can machine on a mill just fine, some things are just more suitable for one of the particular models. Table T Slot Size / Spacing Between. Z Axis Travel (Head). Distance, Spindle to Table. 4-3/4, 2.952? (75MM). Precision Ground ACME Leadscrew W/ Backlash Adjustments on. X and Y Axis. 100 (10 Threads Per Inch). High Precision Tapered Roller Bearings, Fully Adjustable. Overall Height, to reach Maximum top of Z Axis Travel. Height with head at normal working height. Height of Table Working Surface, mounted on optional stand. Front to back, rear of machine to front of Y Axis Handle. Chip Tray Size (At top of base). Width X Axis Table Handles, Tip to Tip. 900 LBS (Without Stand) 1030 (With Stand). 220 Volt Single Phase Power. NO extra charge for residential or anything on these, as long as a truck can get to you, its covered. If you have ANY questions, feel free to message us. Check out our other auctions for more lathes and mills.

Comments Off