2025

3 Flute Carbide End mills Bit ZrN Coating 6mm 8mm 10mm 12mm Shank Milling cutter

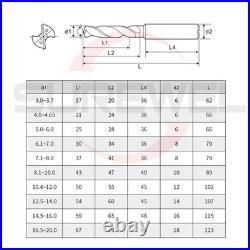

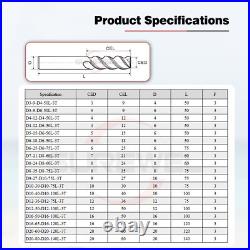

High Efficiency Milling Cutter For Aluminum Color: yellow Specifications: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 16mm Coating: ZrN Applicable materials: copper, aluminum alloy, magnesium alloy, zinc alloy Applicable machines: CNC machining centers, engraving machines, engraving machines and other high-speed Large U-shaped groove, high-efficiency aluminum, rough machining artifact, no knife pattern, non-stick knife, good high-gloss effect ZrN coating increases life by 5 times Using a new composite film coating technology, it is more lubricated, so that it can achieve stable processing even at high temperatures in high-speed operation, and increase the wear resistance of the tool 50° helix angle Large chip flute, 50° helix angle for faster chip removal, smoother cutting and better machining e. You are welcome to visit the SUREWEL TOOLS store! High Efficiency Milling Cutter For Aluminum. Specifications: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 16mm. Applicable materials: copper, aluminum alloy, magnesium alloy, zinc alloy. Applicable machines: CNC machining centers, engraving machines, engraving machines and other high-speed. Large U-shaped groove, high-efficiency aluminum, rough machining artifact, no knife pattern, non-stick knife, good high-gloss effect. ZrN coating increases life by 5 times. Using a new composite film coating technology, it is more lubricated, so that it can achieve stable processing even at high temperatures in high-speed operation, and increase the wear resistance of the tool. Large chip flute, 50° helix angle for faster chip removal, smoother cutting and better machining efficiency. 0.2um micro-particle tungsten steel raw material, with higher wear resistance and strength, is a special milling cutter for high-hardness high-speed cutting applications.

Comments Off