2026

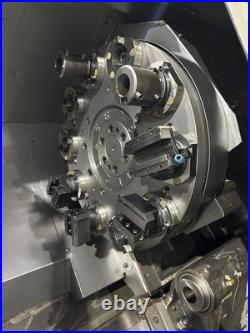

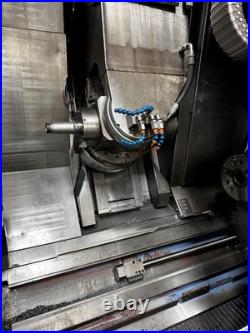

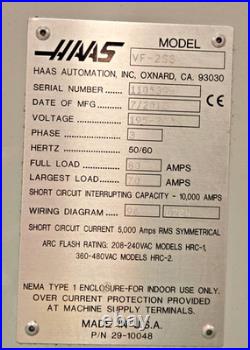

ROEDER RFM600 PRECISION / HIGH SPEED VERTICAL MACHINING CENTER 42k Spindle

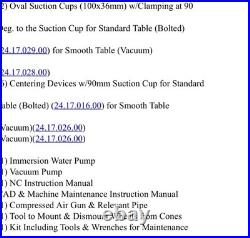

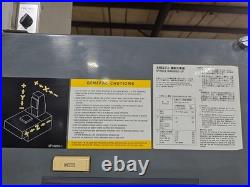

ROEDER RFM600 PRECISION / HIGH SPEED VERT. ALWAYS SERVICED BY ROEDER. FISCHER 42K SPINDLE. HSK E40 TAPER. BLUM LASER TOOLSETTER. UPDATED SPINDLE CHILLER. X & Z BALL SCREWS REPLACED. X, Y, Z – 24″, 20″, 12. TABLE: 28″ X 20″. RMS 6 CONTROL.

Comments Off