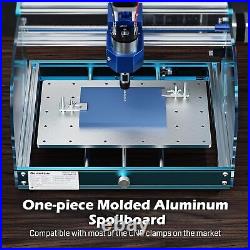

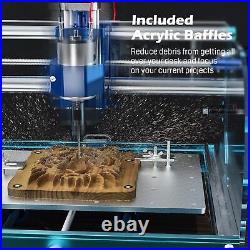

OXMAN CNC Engraver Manchine Full Kit-Ball Screw with 2.2Nm Close Loop Motors. The OXMAN CNC Router is an industrial Grade CNC Newly designed with SFU16 (16mm) Ball Screws and Double Dual Extended HG&MGN Linear Rails trammission on each axis. All key components of the entire machine are installed with precision locaing pins, and all axes are protected by sheet metal and rein-forced aluminum. It is 100% fully self-developed, designed by BulkMan3D International R&D Team and copyrighted by BulkMan3D. The main difference between the 3 versions of OXMAN is the workbench, we recommend OXMAN ULTRA as it comes with complete deluxe workbench. This Full Kit Includes. 1500x1500mm OXMAN CNC Frame Kit (OXMAN or OXMAN PRO or OXMAN ULTRA for choice) (X axis and 2Y axis=SFS1610 Ball Screw, Z axis=SFU1204 Ball Screw) New Design Cable Drag Chain System 1x XYZ Probe (Free Gift) 1x Drill Bits (Free Gift) Wiring Shielded Cable Kit. Spindle Bundle Kit with Dust Cover-80mm – 2.2KW 220V Water-Cooled (Only with DDCS4 V4.1 OFF-LINE Control Box Option) – 2.2KW 110V/220V Water-Cooled Spindle Bundle (High Speed 7 Series 4 Bearings) – 2.2KW 110V/220V Air-Cooled Spindle Bundle (High Speed 7 Series 4 Bearings). Controller Bundle Kit with Stepper Motors – DDCSV4.1 OFF-LINE Control Box with 2.2N. M Closed Loop Stepper Motors – UC300 Mach3 with 2.2N. M Closed Loop Stepper Motors – DDCS4V3.1 OFF-LINE with 2.2N. M Closed Loop Stepper Motors. The Ball screw nut fixing and dismounting requires professional tools or done by professional stuffs! Never rotate the ball screw nut over the ball screw end! The OXMAN CNC excels at Cutting and 3D Carving through plastics, foam, softwood, hardwood and even soft metal such as aluminium and brass. Compatible Material for Cutting/Milling/Engraving : Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam and so on. Drill Bits & Milling Cutters. The OXMAN CNC can create intricate 3D carvings like wood artware, inlays, adverting logo, plaques, furniture, amazing art works and so much more. All the widely used applications can be achived here! DDCSV4.1 OFFLINE Control Box With 4pcs (57HSE2.2N) 2.2N. BulkMan 3DB-PRO DDCSV4.1 Industrial-gradeController Box is a high-performance control system specially designed to meet the needs of industrial manufacturing. Its rugged exterior and state-of-the-art technology ensure precise control of all CNC machine functions. The DDCS V4.1 is a standalone/offline controller, supports comprehensive Fanuc G code set file and can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller, no size limited of the G-code file. The G-code design supports various software of CAD/CAM, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on. Meet the needs of various CNC machines: Engraving machines, Milling machines, Routers, Cutting. Etc. If you choose this controller bundle, the spindle options can only choose 1.5KW 220V water-cooled spindle bundle, and this spindle bundle does not include VFD. DDCS V4.1 4Axis Offline Control Box System with MPG Handwheel. This Control Box Includes. DDCS V4.1 4Axis Offline Control Box as Picture Shown. MPG Handwheel as Picture Shown. 4pcs (57HSE2.2N) 2.2N. Hardware Configuration inside this Control Box. 1x DDCSV4.1 Controller. 1x MC Power Supply S800-36V. 1x MC Power Supply LRS-75-24. 1x MC VFD 2.2KW/220V Or 2.2KW/110V. 4x HBS57S Stepper Driver. 1x MC Plug-in Filter CW4L2-20A. 1x MC Wire-lead Filter CW1B-10A. 1x MC 4-channel relay-24V. 1x MC Fan 8025-24V. 2x MC Fan 6010-24V. 1x MC DB37 Terminal Block. Tips: Most Internal cables and modules inside this control box have been pre-connected, just follow our instruction to simply plug this box and it can work for your machine! DDCSV3.1 OFFLINE Controller Bundle With 4pcs (57HSE2.2N) 2.2N. This DDCS4 V3.1 Controller Bundle contains all the hardware for powering and controlling your OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC, Ox CNC. Or other CNC machine. DDCS V3.1 numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation. The internal operating system is Linux based. The panel layout structure of the CR8-500 is very rational to save space. All operations are controlled by only 17 keys and a comprehensive G code set is supported. This controller bundle comes with 2.2N. UC300 Mach3 Controller Bundle With 4pcs (57HSE2.2N) 2.2N. This MACH3 Controller Bundle contains all the hardware for powering and controlling your OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC, Ox CNC or other CNC machine. This UC300 system is an upgrade to our NVUM system. This Controller Bundle will allow you to use a Digital Dream UC300 Controller with a 4-axis machine CNC machine using MACH3 software. 2.2KW(110V/220V) Water Cooled Spindle Bundle. The 2.2KW Water Cooled Spindle is a heavy duty router, and due to the water cooled system, is comfortably capable of running for a long time without stopping, which makes it ideal for long, complicated jobs or applications. The VFD Inverter in this bundle are high quality from a well respected brand; Huanyang – an industry leader in CNC machining. It contains all the hardware for mounting a 2.2kW Water Cooled Spindle on a OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC Machine or other CNC machine. 2.2KW Spindle Size: ø 80 x 238mm (Diameter: 80mm x Length: 238mm). Material: The cover is made of 304 stainless steel, and the water jack is high compression casting aluminium tube, red copper coil. Voltage: 2.2KW for 110V or 220V. AC Rated Current: 8 A. Max Rotation Speed: 24000 R/min. Water Cooled Run out: 0.01 mm. Bearing: 7005 bearings (3pcs), 7002 bearing (1pc). Coaxality: 0.025 mm (2.5 microns). Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4. Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. Number 4 is connected to the Earth wire Lubrication: High temperature resistance grease lubrication. 2.2KW Water Cooled Spindle Bundle comes with ER20 Collets from 1 mm to 13 mm. 28pcs:1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm. 2.2KW (110V/220V) Air Cooled Spindle Bundle. The 2.2KW Air Cooled Spindle Kit is a very powerful Spindle we offer, which is a must have for anyone who takes their CNC machine serious. The VFD Inverter in this kit are high quality from a well respected brand; Huanyang – an industry leader in CNC machining. It contains all the hardware for mounting a 2.2KW Air Cooled Spindle on a OX-MAN CNC, Ultimate Bee, QueenBee Pro, WorkBee, Lead CNC Machine or other CNC machine. 2.2KW Spindle Size: ø 80 x 195mm (Diameter: 80mm x Length: 195mm). Material: The cover is made of 304 stainless steel. Power: 2.2 KW. Runout: less than 0.005 mm. Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4 Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. 2.2KW Water Cooled Spindle Bundle comes with ER20 Collets from 1 mm to 13mm 28pcs:1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm. Terms of Sale (VAT). Return must include all original package and accesorries, item must in good condition. We will work with you to until you are satisfied. We will try our best to solve your problem to your satisfaction. We are always here with you! Our working time is 8 :30AM – 6:30PM from Monday – Friday.